KMC Controls VEZ-4x Series User Manual

Installation guide, Way/3-way, npt, zone control valves, Mounting valve body

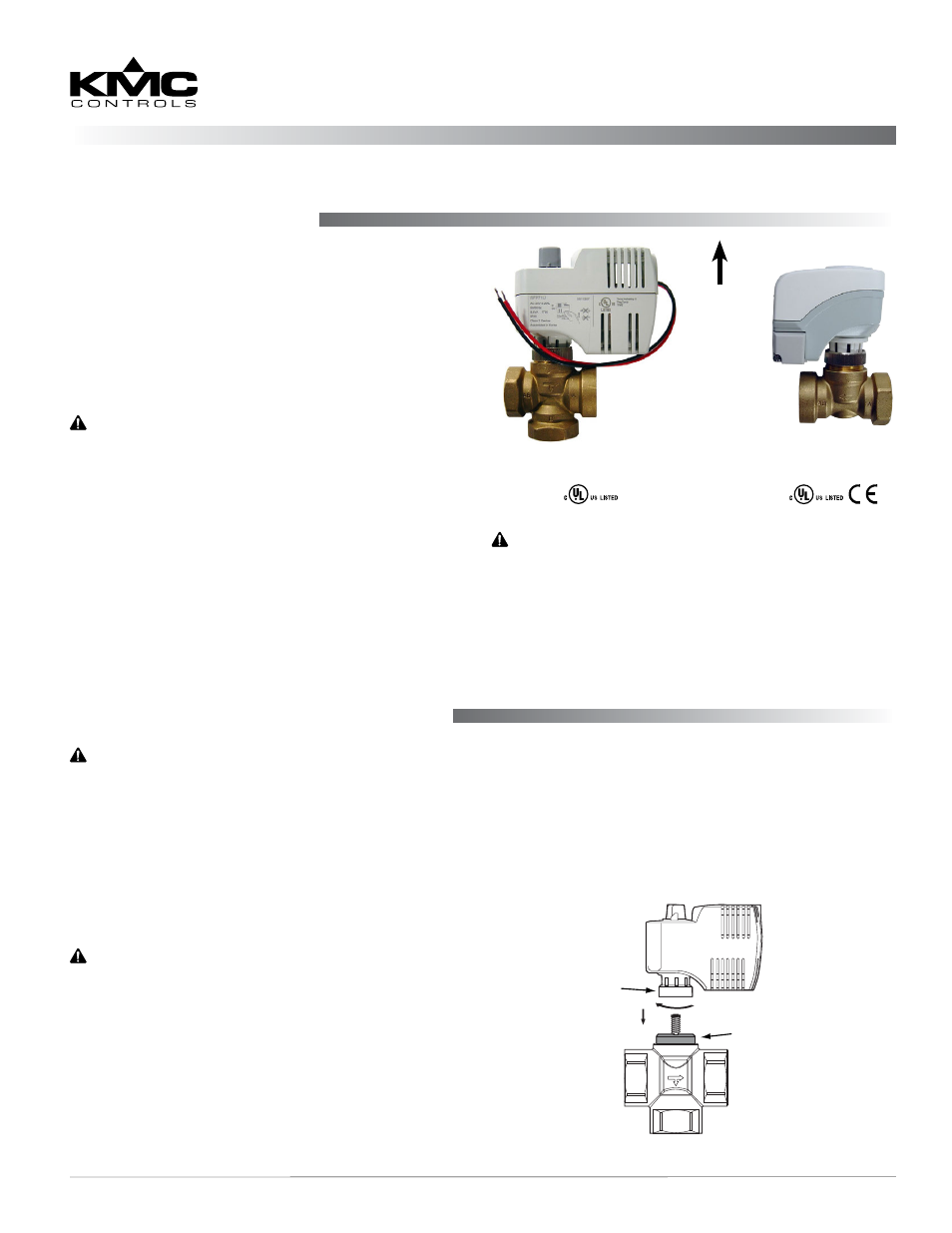

VEZ-4x Series, 2-Way/3-Way, NPT Zone Control Valves (1/2 to 1")

1

Installation Guide

Installation Guide

2-Way/3-Way, NPT, Zone Control Valves (

1

⁄

2

to 1")

VEZ-4x Series

Mounting Valve Body

1. Clean the lines upstream from the valve. Remove

any debris larger than 0.06" (0.015 mm).

2. Align the valve’s flow indicator with the system

flow (see page 4 for 3-way mixing or diverting

applications).

3. Mount the valve so the actuator is positioned over

valve.

CAUTION

To prevent condensation from dripping onto the

actuator housing, mount the valve with the actuator

in the upright position or, at most, at a 45° angle.

4. Seal valves with approved pipe sealant.

5. Using two wrenches, secure the valve to the pipe.

Torque should not exceed 75 ft-lbs. (102 N

•

m).

6. Eliminate air from the system to keep the valves

full of fluid during operation.

NOTE: If the system experiences large amounts of

debris, steps should be taken to keep the

system clean.

Mounting Actuator on Valve Body 1

Wiring 2

Operation 4

Maintenance 4

Select Specifications 4

More Information 4

Important Notices 4

UP

CAUTION

Using mineral oil lubricants or other incompatible

substances in system fluids may damage EPDM

rubber seals in valves. Before using any lubricant or

additive in a water or ethylene glycol base, consult

the substance manufacturer for compatibility with

EPDM (Ethylene Propylene Diene Monomer).

2-Way with Tri-State or

Proportional Actuator

3-Way with 2-Position

Fail-Safe Actuator

1

2

Mounting Actuator on Valve Body

Ring Nut to

Valve Body

Black Plastic

Attachment

Support Ring

CAUTION

If mounting the actuator to a valve already in-line,

close the shut-off valves in the piping (upstream

first, then downstream) or switch off the pump to

allow the differential pressure in the valve to drop.

1. To remove an existing actuator, disconnect

the wiring, turn the ring nut (coupling piece)

counterclockwise until it is loose, and pull off the

actuator.

CAUTION

The black plastic actuator attachment support ring

must be in place on top of the valve bonnet before

mounting the actuator or damage to the actuator

connection may result.

2a. For NO actuators (“A,”“M,” and “P”), place the

actuator on top of the valve body and firmly

hand-tighten (only) the ring nut.

NOTE: The last digit of valve model number

represents the type of actuator.

Mounting Actuator on Valve Body

2b. For NC actuators (“B,”“F,” “N,” and “Q”),

manually rotate and latch open the actuator (or

proper valve close-off may be affected). See the

Manual Override section on page 3. Then place

the actuator on top of the valve body, firmly

hand-tighten (only) the ring nut, and return the

actuator to its normal position.