Rcc-1009/1109 switching/diverting, Rcc-1013 repeating, Rcc-1102 averaging – KMC Controls RCC-1100 Series User Manual

Page 2: Accessories, Maintenance, Important notices, Important notices 2, Caution

RCC-1000/1100 Series

2

Installation Guide

© 2011 KMC Controls, Inc.

100-019-01I

KMC Controls, Inc.

19476 Industrial Drive

New Paris, IN 46553

574.831.5250

www.kmccontrols.com

Important Notices

The material in this document is for information

purposes only. The contents and the product it

describes are subject to change without notice.

KMC Controls, Inc. makes no representations or

warranties with respect to this document. In no event

shall KMC Controls, Inc. be liable for any damages,

direct or incidental, arising out of or related to the

use of this document.

Maintenance

No routine maintenance is required. Each compo-

nent is designed for dependable, long-term reliabil-

ity, and performance. Careful installation will also

ensure long-term reliability and performance.

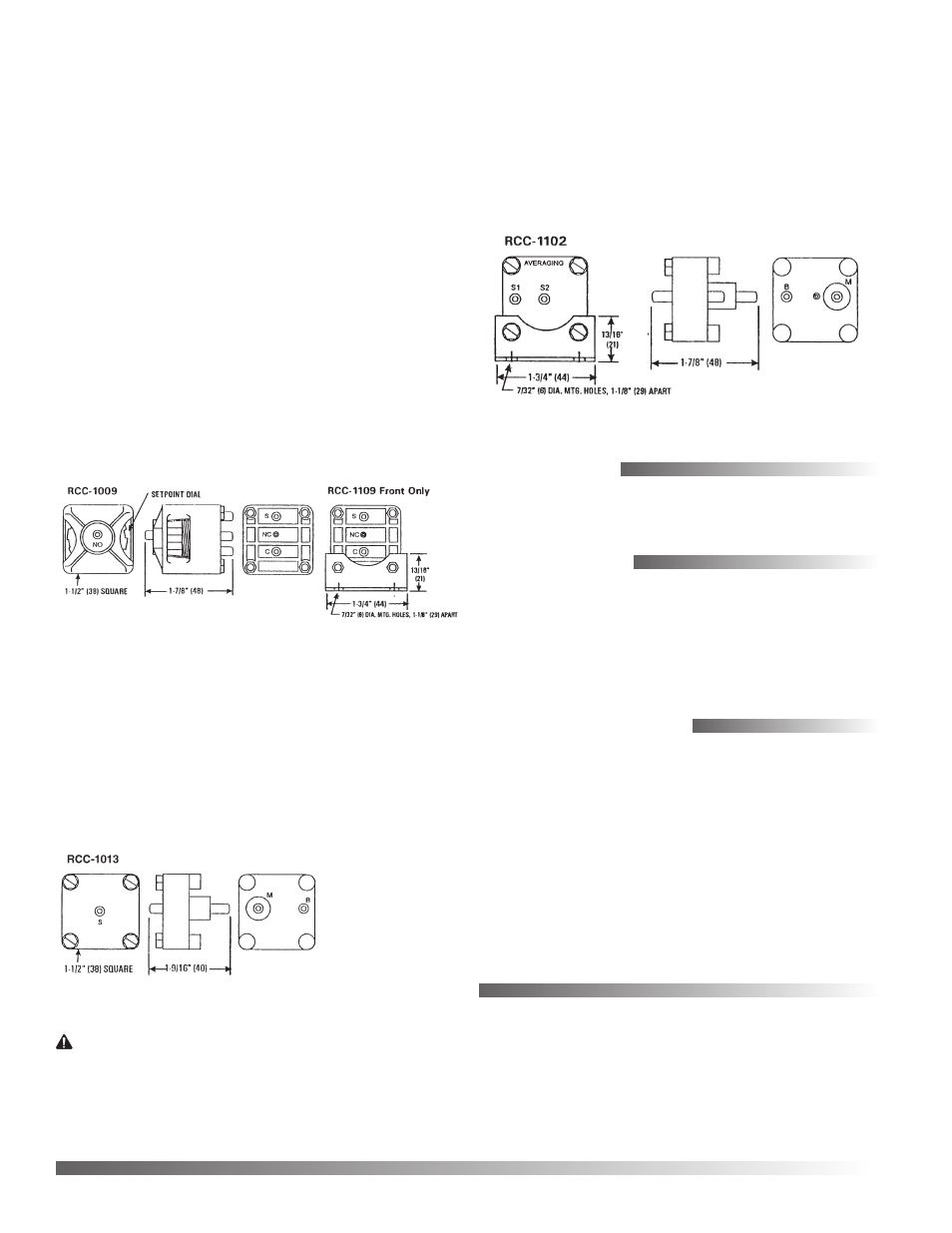

RCC-1009/1109 Switching/Diverting

Each unit is factory set to switch between 18 and 23

psi. This allows the unit to match most two-pressure

main air systems. This device is not “snap-acting” (it

must receive a positive pressure change at its signal

port to switch).

1. Apply air pressure to Port C.

2. Apply the lower switching signal to Port S.

3. With an accurate pressure gauge, check that the

pressure at Port NO is equal to the pressure at

Port C. If not, adjust the setpoint dial until the

pressures are equal and no pressure is detected at

Port NC.

4. Apply the higher switching pressure to Port S.

5. Check that the pressure at Port NC is equal to the

pressure at Port C. If not, adjust the setpoint dial

until the pressures are equal and no pressure is

detected at Port NO.

HMO-4511

Replacement mounting bracket

Accessories

The setpoint dial can be rotated within the body to adjust the switching point. One turn yields

approximately 6 psi change in the switching point. Each unit is factory-set to switch between

18 and 23 psi, which allows it to match most two-pressure main air systems. This device is not

“snap-acting” (it must receive a positive pressure change at its signal port to switch).

RCC-1013 Repeating

1. Apply main air pressure to Port M.

2. Connect Output to Port B.

3. Connect Input to Port S.

No calibration is required

.

Main air is Port M and output is Port B. The input signal to be repeated is connected to Port S.

RCC-1102 Averaging

1. Connect Main air to Port M, 20 psi with 30 psi

maximum.

2. Connect Output to Port B.

3. Connect the inputs for averaging to Port S1 and

S2.

No calibration is required.

Main air is Port M and output is Port B. Inputs to be averaged are applied to S1 and S2.

CAUTION

Pneumatic devices must be supplied with clean, dry

control air. Any other medium (e.g., oil or moisture

contamination) will cause the device to fail.