Pyromaster, H33bdvrrn/p – Vermont Casting H33BDVRRN User Manual

Page 6

6

Pyromaster

©

H33BDVRRN/P

10004798

Noncombustible materials such as brick or tile may be

extended over the edges of the face of the fireplace.

DO NOT cover any vent or grille panels.

If a Trim Kit is going to be installed on the fireplace, the

brick or tile will have to be installed flush with the

edges of the fireplace.

Final Finishing

The gas pipeline can be brought in through the rear of

the appliance as well as the bottom. Knockouts are

provided on the bottom behind the valve to allow for the

gas pipe installation and testing of any gas connection.

It is most convenient to bring the gas line in from the

rear right side of the valve as this allows fan installation

or removal without disconnecting the gas line.

The gas line connection can be made with properly

tinned 3/8” copper tubing, 3/8” rigid pipe or an ap-

proved flex connector. Since some municipalities have

additional local codes, it is always best to consult your

local authority and the National Fuel Gas Code, ANSI

Z223.1 in the USA or the CSA-B149.1 installation

code.

Gas Line Installation

When purging gas lines, the front win-

dow frame assembly must be removed.

1. Choose the unit location.

2. Place the unit into position and secure it to the floor

with 1

¹⁄₂

” (38mm) screws, or nails. The holes to

secure the unit to the floor are located just behind

the access door grille on the left and right side of the

unit.

3. Frame in the fireplace with a header across the top.

It is important to allow for the finished wall face when

setting the depth of the frame.

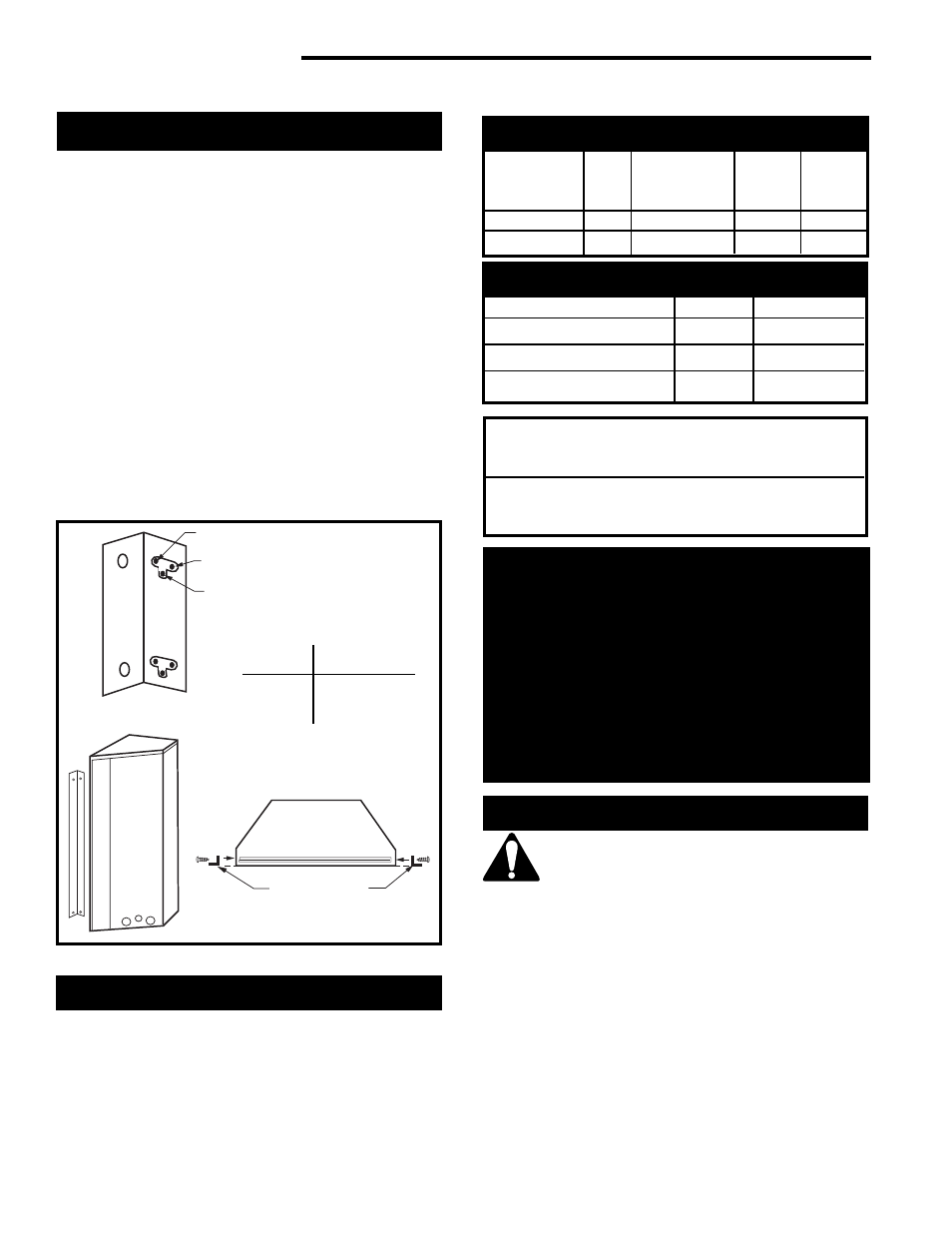

4. Attach the fireplace to the frame using the adjustable

frame drywall strips (located behind the access door

for shipping). Preset the depth to suit the facing

material of the wall. The strips are adjustable to 1/2”

(13mm), 5/8” (16mm), or 3/4” (19mm). (Figs. 3 & 4)

5. Screw through the slotted holes in the drywall strip

and into the pre-drilled holes in the fireplace side.

Measure from the face of the fireplace to the face of

the drywall strip to confirm the final depth.

Framing and Finishing

Natural

LP (Propane)

Minimum Inlet Pressure

5.5” wc

11” wc

Maximum Inlet Pressure

14” wc

14” wc

Manifold Pressure

3.5” wc

10” wc

Gas Inlet and Manifold Pressures

H33BDVRRN/P

Certified To

ANSI Z21.88b-1999 / CSA 2.33b-M99

Vented Gas Fireplace Heaters

High Elevations

Input ratings are shown in BTU per hour and are

certified without deration for elevations up to

4,500 feet (1,370m) above sea level.

For elevations above 4,500 feet (1,370m) in USA,

installations must be in accordance with the

current ANSI Z223.1 and/or local codes having

jurisdiction.

In Canada, please consult provincial and/or local

authorities having jurisdiction for installations at

elevations above 4,500 feet (1,370m).

C

B

A

Adjustable Drywall Strip

(Nailing Flange)

Adjustable 1/2”,

5/8” & 3/4”

Spacing

FP1023

Screw

Drywall

Position

Depths

A

1/2” / 13mm

B

5/8” / 16mm

C

3/4” / 19mm

Fig. 4 Adjustable drywall strip (nailing flange).

Gas Specifications

Max.

Min.

Model

Fuel

Gas Control

Input

Input

BTU/h

BTU/h

H33BDVRRN

Nat

Millivolt

15,000

10,500

H33BDVRRP Prop

Millivolt

15,000

11,250