ETS-Lindgren 2075 MiniMast (Archived) User Manual

Page 14

Electrical Installation

MODEL 2075 MINIMAST™

10

© EMC TEST SYSTEMS, L.P. – MARCH 2002

REV D – PN 399235

branch circuit of adequate current capacity to keep voltage drop to

a minimum during startup and running.

Check that the conductor size is adequate for the motor load and

the distance from the mains source. Improperly sized conductors

will lead to a high voltage drop in the power conductors and cause

reduced starting torque and premature motor failure. For longer

runs, increase the wire size in accordance with the wire selection

guide shown below. Never use smaller than 14 AWG for any

installation.

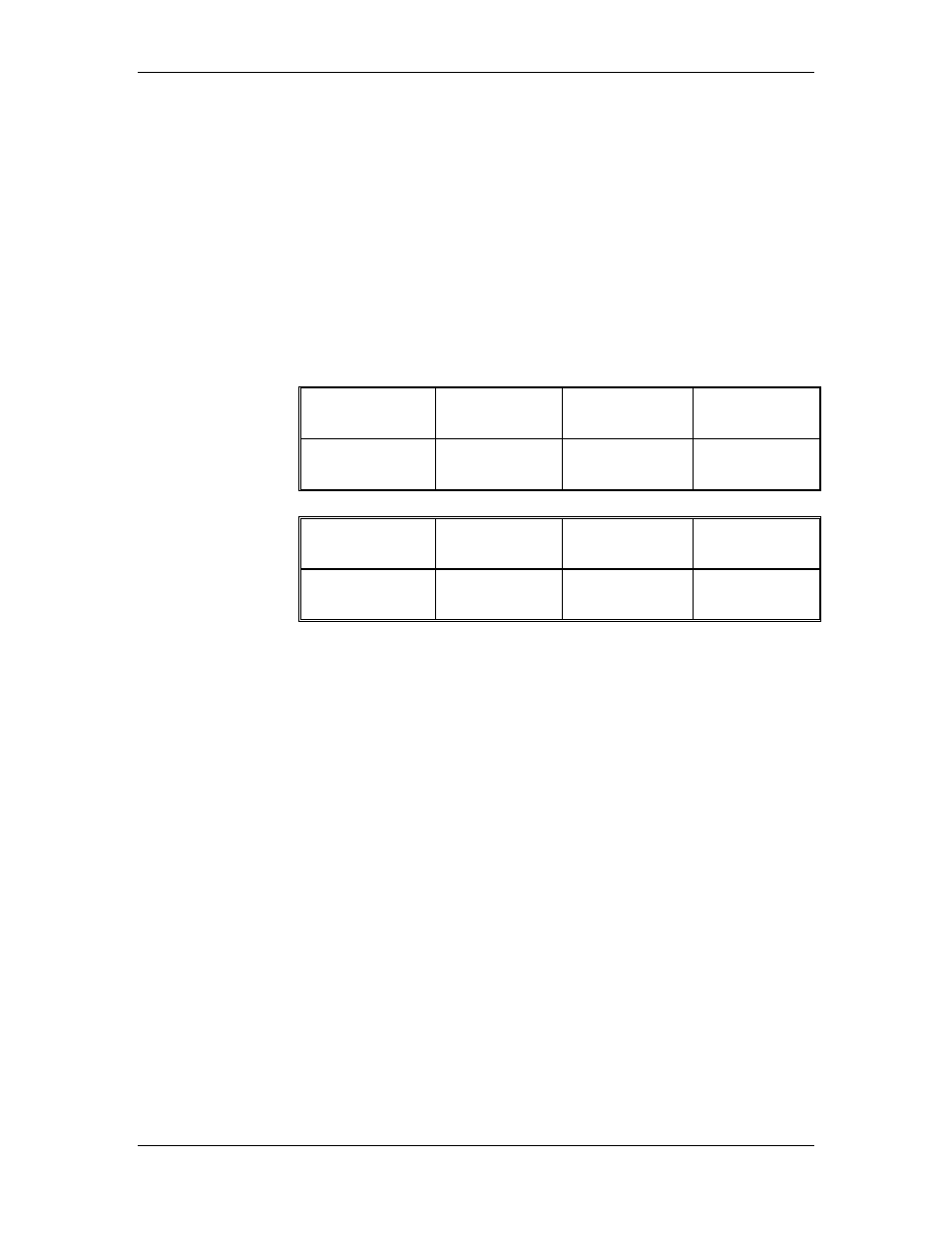

Length of wire

@ 115V

0-15.24 m

(0-50 ft)

15.24-30.48m

(50-100 ft)

30.48-60.96 m

(100-200 ft)

Wire gauge

required

14 AWG

10 AWG

8 AWG

Length of wire

@ 220V

0-15.24 m

(0-50 ft)

15.24-30.48m

(50-100 ft)

30.48-60.96 m

(100-200 ft)

Wire gauge

required

14 AWG

14 AWG

14 AWG

If the power cord needs to be replaced, it is recommended that this

alteration be performed at the factory. However, if it is necessary

to modify the electrical cord on site, a qualified, licensed

electrician should perform this operation.

To remove the power input cord:

1. Disconnect the power cord from the supply mains.

2. Remove the clamps that secure the enclosure cover plate in

place and lift the lid.

3. Loosen the plastic strain relief that is around the power cord on

the exterior of the unit.

4. Using a Phillips head screwdriver locate and remove the ten

screws around the edge of the motor base face plate. Gently

remove the face plate and set it down in front of the opening.

IMPORTANT

Do not pull the faceplate away quickly as there

are wires that connect to the faceplate that should remain intact

during this procedure.

Archived 3/18/10