Trouble shooting guide - reverse osmosis systems – Environmental Water Systems RO4-UV User Manual

Page 19

19

www.ewswater.com O: 702.256.8182; M-F 8:30am-4:30pm PST E: [email protected]

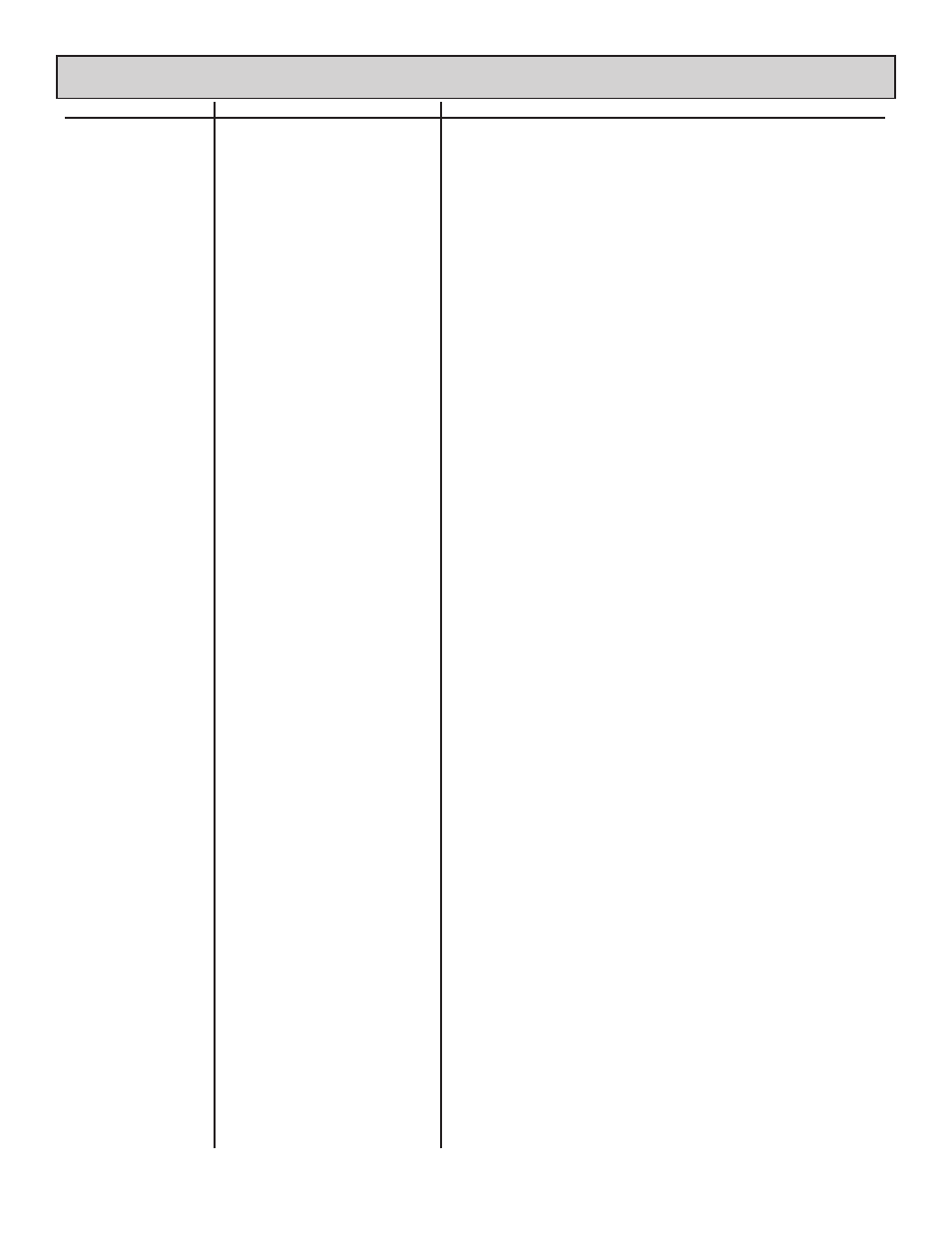

Trouble Shooting Guide - Reverse Osmosis Systems

Air in system, System start-up

Filter or membrane replacement

New installation, changing filters,

Open/close and open of water supply

to home or in home

Hot or High feed water temperature

High feedwater TDS

RO Membrane replace

High feedwater temperature

Post filter elements

Pre- and Postfilters

Pre-Treatment needed

Filter/Membrane/UV issues

Storage tank water issue

Need to replace filters

System was idle, stored or misused

for a long period of time.

System under unfavorable conditions

or changing water conditions

Hydrogen sulfide, iron, manganese is

in the household water supply, pres-

ence of iron/sulfur bacteria

System misapplied

TDS “Creep” Tank has never been

completely emptied and filled

Clogged filter(s)

Low water pressure

RO membrane is new

RO membrane issues

RO membrane is expended

Product water and drain water tubing

or connections are crossed

No drain flow

System shut off valve is not closing

New filters not flushed properly

Restricted drain flow

Problem

Water

Quality

Possible

Causes

Solution

Water Cloudy

Salty Taste or Whitish

Ice Cubes

TDS Test less than

75% Rejection

Low Quality Water

Taste, Odor

Unpleasant taste and/

or odor

Metallic flavor

Discoloration

Rotten egg smell from

water

High Total Dissolved

Solids (TDS) in the

Product Water

Low Quality Water

Taste, Odor

and/or

Tank fills too fast

Low Quality Water

Taste, Odor

and/or

Tank fills too fast

Air in system is a normal occurrence with initial start-up of RO system. This milky

or cloudy look will disappear during normal use within 1-2 weeks. Condition can

reoccur after any filter change-out

Empty and fill tank 3 times to reduce air and fines from system and/or filter

replacement start-up

Water supplied to unit must be below 95°F

Feedwater TDS levels above 500 ppm can result in lower quantity and quality

product water. 1 psi loss per every 100 ppm above 500 ppm. Treat the same as

low feedwater pressure. Increase water line pressure or may need booster pump

for system (see Model No. RU500T35/BP for well water)

Membrane replacement should occur when rejection rate has dropped below

70%

Feedwater temperatures above 95°F can produce problems, cool water or find

another supply

New filters can release small air bubbles and small fines which show as addi-

tional TDS in the product water. Follow proper start-up instructions

Pre- and Post filters require replacement

Feedwater pretreatment may be necessary for water supplies with high levels

of iron, hydrogen sulfide, water hardness, etc. which may be exceeding system

tolerance parameters

Replace as needed

Empty tank, sanitize, empty, flush and refill

Replace filters and follow start up procedures

Flush system by running water, replace filters and/or disinfect

Determine what changed in your water supply and Flush, Replace or change

type of water treatment system based on local water conditions. Call your mu-

nicipality or have your well re-tested.

Hydrogen sulfide, iron and manganese must be removed from household water

supply before filter system.

Visit our web site for other systems.

At night before bedtime, open dispenser, close other devices, then empty all the

water from the tank. Allow water to produce overnight. Open other devices after

tank is completely filled. Do this quarterly or as needed.

Replace filter(s)

Feed water pressure must be above 40 psi. Check incoming water at supply

New membrane has a preservative. Follow correct start-up procedure and empty

tank 2 times before usage

If membrane life is unusually short, find and correct the problem.

Replace membrane.

Correct tubing and plumbing connections

Clear or replace drain restrictor. Drain line is clogged or restricted Clear or re-

place air gap line or faucet

Replace shutoff valve

Flush with several full tanks of product water

An increase in feed water TDS will give a corresponding increase in product

water TDS

Blocked brine line will foul membrane, decreasing production and rejection rate.

Check the drain line for obstructions or restrictions blocking the flow into the

drain pipe and air gap (if applicable).

Feedwater below 60 psi will produce lower quantity and quality than the mem-

brane specifications.

Feedwater less than 35 psi should consider using a low pressure boost pump.

Booster pump requirement, inquire with web site or our offices

Feedwater above 75 psi should be regulated to a maximum of 75 psi into the

system