Trouble shooting guide - reverse osmosis systems – Environmental Water Systems RO4-UV User Manual

Page 17

17

www.ewswater.com O: 702.256.8182; M-F 8:30am-4:30pm PST E: [email protected]

Possible

Causes

Solution

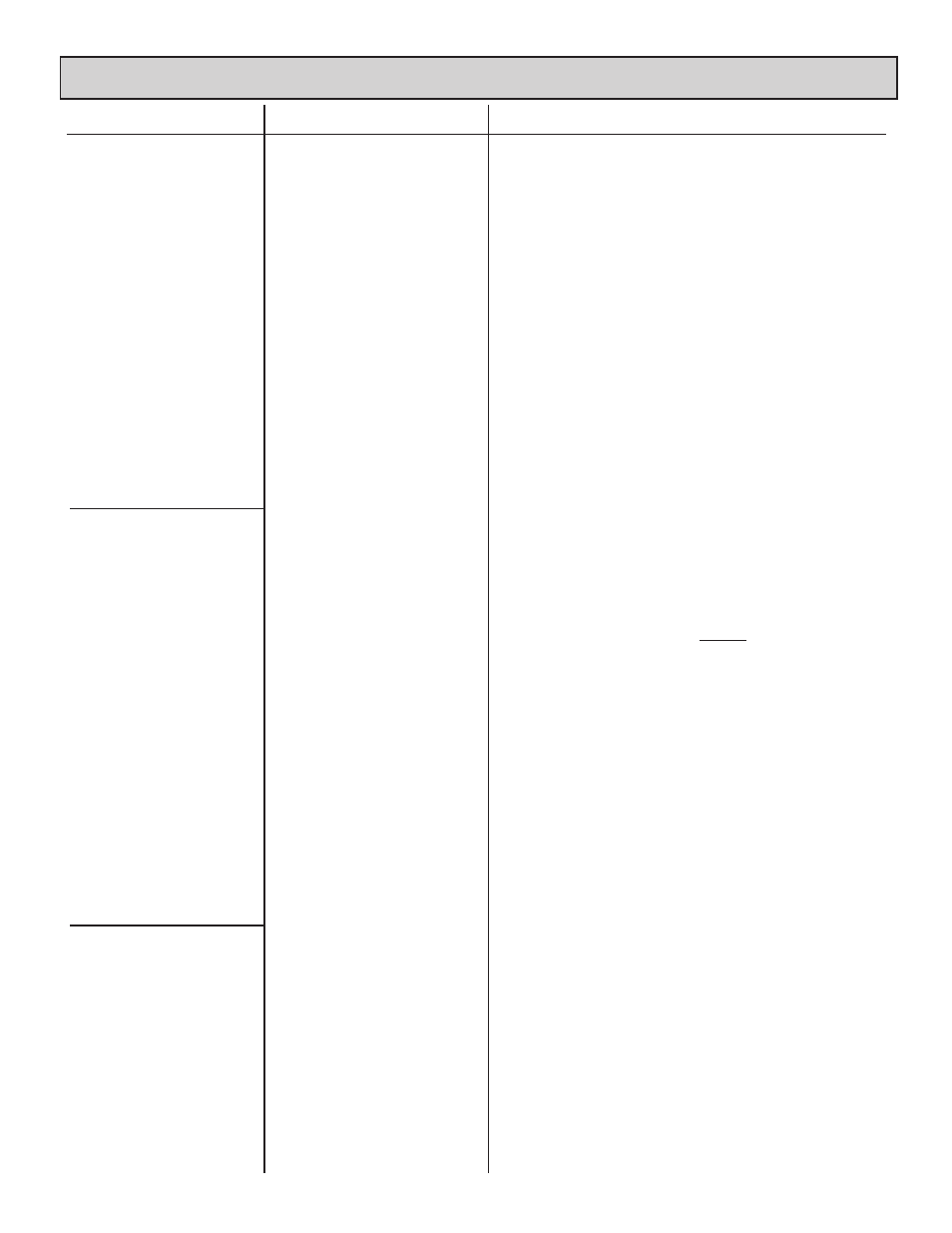

Trouble Shooting Guide - Reverse Osmosis Systems

Problems with Start-Up

&/or Filter Replacements

No water after installing system

No water after replacing filters,

in-line filter, &/or membrane

Problem - Leaks

Connections & Tubing

Any or All Leaks

Leaks at any of the

Tubing Connections:

See colors below:

Red - Incoming Supply

Blue - to Dispenser

Yellow - to Tank

Black - to Drain

Leak at FACTORY INSTALLED

fittings

Leak at plastic compression

fitting at UV Module

(option, if applicanle)

Leak at Inlet Water Supply Con-

nection

Problem Leaks - Faucet

Leak at the supplied faucet spout

Leak at the supplied faucet base

by handle (brass “T”)

Leak at the connection to supplied

faucet

Leak at another Mfg’s faucet or

connection to another device

Water running out of Air Gap adap-

tor of faucet

Improper start-up of the unit upon

installation or filter replacement

It takes hours after a proper install to

have a full tank for use

Filters amd membrane placed in the

wrong order

The interconnection between the inlet,

outlet, drain and tank lines can cause

air in the unit at the shutoff valve. Air

in lines, and at this valve, will not allow

RO to function properly.

Tank valve is closed

Tank pressure is off,

Tank pressure too low or too high

Connections of tubing incorrect

Drain line and/or drain hole restricted

or clogged

Excessive pressure or pressure

surges above 75 PSI

Various causes to inspect

See the Following;

•If cut, is the tubing cut with a straight

end to grab squarely?

•Is the tubing inserted completely into

fitting?

•Broken collect or fitting

•Is there a problem with the collet and

the quick-connect fitting?

•Tubing incorrectly removed

•Damaged in shipping,handling, and/

or delivery

Same as above

Damaged in shipping,handling, and/

or delivery

Various causes to inspect.

Angle Stop valve may not be appli-

cable or installed correctly

Spout needs to be re-inserted

O-ring at inserted brass piece or “T”

that holds and operates handle

Compression fitting & other connec-

tions need to be properly made

All connections need to be properly

made

Black 1/4” & 3/8” tubing misinstalled

or backwards

Drain saddle not allowing water to

drain into trap properly

Start with the start-up procedures and follow them as if the unit was just

installed

Make sure start-up was performed correctly and wait for tank to fill. Fol-

low instructions for proper start-up

Make sure membrane is in middle, Stage 2 and filters are in correct locations

Air in Lines “Burping Procedure”

REPEAT AS NEEDED.

Then close the dispenser, open tank valve, only open (if applicable) water

supply to other connected devices once and only once the tank has filled

completely.

Open valve, in line or parallel with yellow tubing, close other devices and

begin proper start-up procedure.

The tank air pressure should be 5-7 psi without water in tank for proper

operation. Pressure variances due to higher elevations may occur. Under or

over-inflation will prevent proper operation of system. Check with accurate

(0-20) gauge Empty tank and adjust (if needed) using a bicycle or sports

ball pump. Begin proper start-up procedure

Inspect and follow all connections of all tubing

Follow proper instructions for Air Gap installation and connections

Check hole for proper draining and proper drain saddle installation

Check for proper drain location

Pressure reducing valve (PRV) at main water supply to maintain pres-

sure at or below 75 PSI or the addition of a Pressure Limiting Valve

(item# FMP-60) on the inlet tube prior to the point of use unit

•Follow instructions for Connection of Tubing.

Access the filter unit, remove tubing by depressing the collet and pulling

tubing out. Using a utility razor knife, squarely cut 1/2” off tubing from the

end. Make sure end of tubing is not flattened Reinsert the tubing into the

fitting as far as possible. Check for leaks.

•Tug on tubing (do not pull hard) to check fitting and the integrity of the

connection

•Upon inspection, prior to install or a result of proper start-up and inspec-

tion and fitting is damaged,

Replace simple part (call for proper fitting part)

Same as above

Replace simple part (item# fc-uv-jaco)

•Check connections and/or correct.

•Follow the inlet supply water instructions in this manual and/or install

the preferred inlet connection

•Spout pulls out from faucet body that’s why it swivels. Spout has 2 o-

rings at base and is inserted completely into bottom of body to prevent

leaking.

•Replace the supplied faucet (item# depends on any finish option)

•Check connections at various locations and re-connect, re-insert,

tighten and/or correct.

•Consult with Mfg of other product and/or installer to check connections

at various locations and reconnect and/or correct.

Follow proper instructions for Air Gap installation and connections

Check hole for proper draining and proper drain saddle installation

Check for proper drain location