Series 406x storefront installation instructions – EFCO 406X Series User Manual

Page 9

Series 406X Storefront Installation Instructions

EFCO 2014

Page 9

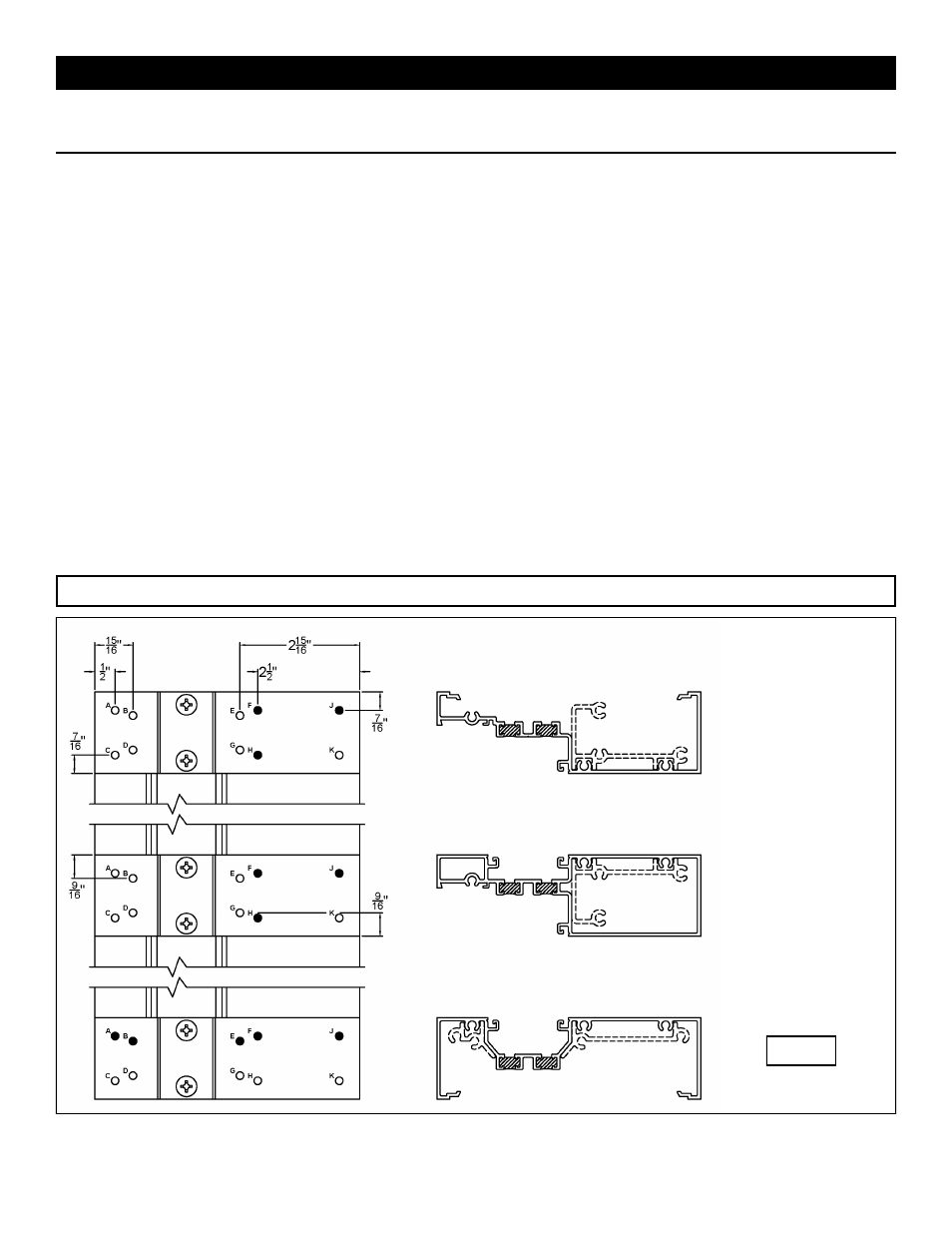

Section 3B. Shear Block Fabrication

The shear block system is a fabrication and erection method that permits the preassembly of single units in the

shop or at the job site. These units are joined with shear blocks and then installed as an assembled unit in the opening

on top of any sill flashing that is used.

Fabrication Steps:

1. Measure the opening to determine the cut lengths of the frame components.

Allow a minimum 1/4” clearance at head and jambs and 3/4” clearance at the sill for shims and caulking.

Allow extra clearances, if necessary, to accommodate building tolerances and building movement.

2. Cut the vertical to frame size.

Verticals must run through.

If the opening has an entrance, see the appropriate frame and door fabrication installation sheets.

Door jambs run to the floor and are cut longer than other verticals.

3. Cut horizontal members to day lite openings. (Between vertical members)

4. Cut the horizontal glass stops to day lite opening minus 1/32”. (DLO - 1/32”)

5. Drill holes for shear block screws on vertical members and prepare attachment holes on horizontal members per one

of the following methods.

Drill jigs are available. (See Page #6)

Layout holes per details #4,5,6 and drill.

Use punch press with appropriate die set.

Drilling Patterns

Outside Glazed

Bead-Down

Shear Block

Verticals

Left Hand Shown,

Right Hand

Opposite

Use Drill Jig

#DJ53

Use a .180” dia.

No. 15 drill bit at

darkened holes

only.

Fig. #4