EFCO S5500 Inside Glazed User Manual

Page 29

EFCO CORPORATION 6/2012

PART NO. Y552

Series 5500 Inside Glazed Installation Instructions

Section V: Glazing Installation

IMPORTANT NOTE: EFCO recommends using conventional tubular spacers

only for insulated glass units with the S-5500. This is due to the possible

collapse of the spacer when used with drive-in wedge glazing gaskets.

NOTE: Clean all glazing pockets prior to glazing. This is

necessary to avoid clogging the weep system as well as to

prevent staining of the exterior metal and glass surfaces.

STEP #1 INSTALL GLAZING MATERIALS

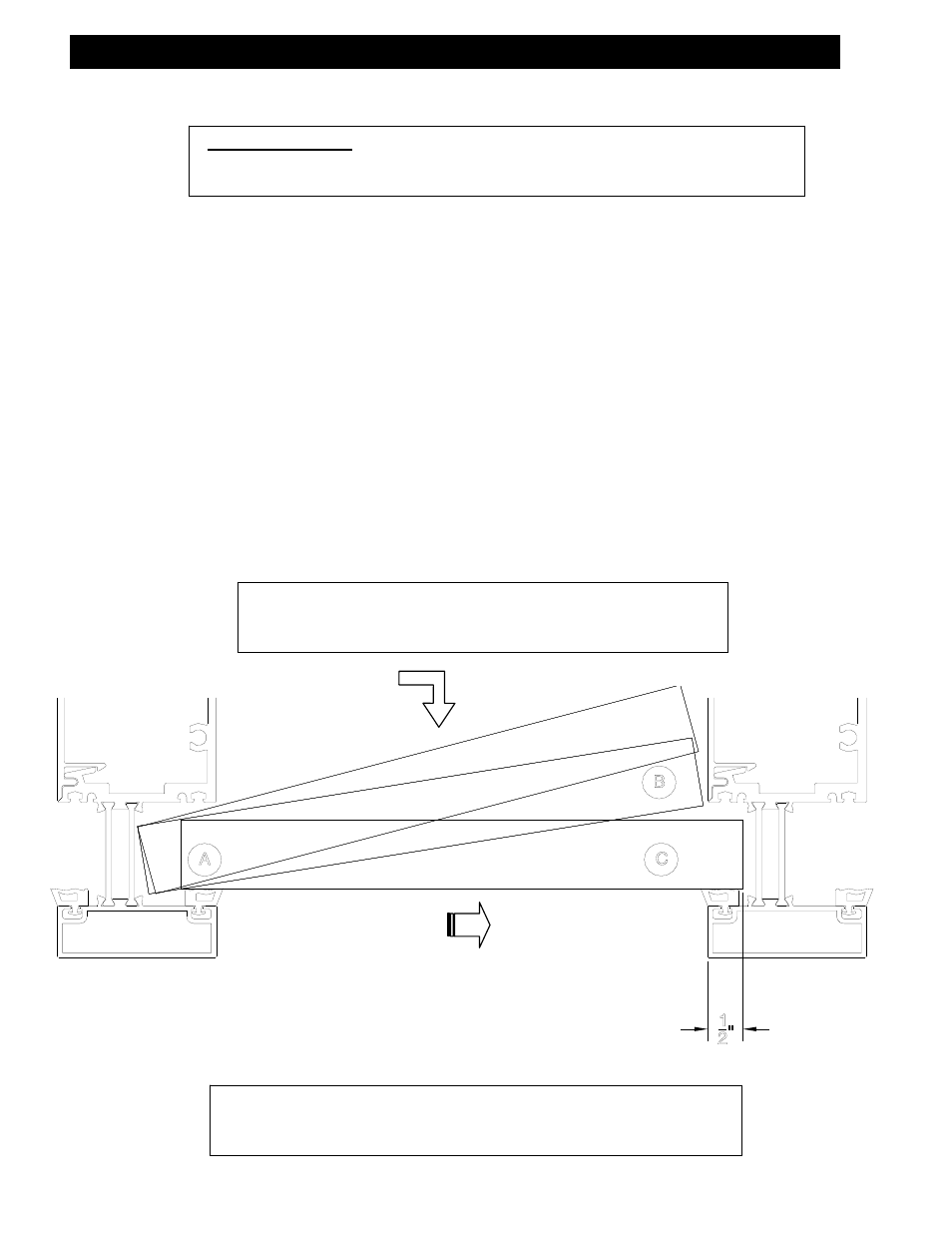

A. Using suction cups, gently insert a glass edge (or other glazing infill) into the deep

pocket of the vertical mullion.

B. Swing the opposite edge of the glazing in plane with the shallow pocket of the ad-

jacent vertical mullion, and lower the glazing onto the setting blocks.

C. Position the glazing in the center of the opening maintaining a 1/2” glass bite

around the entire perimeter, except at I.G. heads, where the glass bite is 3/8”.

D. Lift the infill slightly off the setting blocks, and press the glass firmly against the

exterior glazing gaskets at the sill horizontal.

STEP #2 INSTALL TEMPORARY RETAINER GASKETS

A. Use 2” long pieces of the interior wedge gasket to temporarily compress and hold

the glass in the glazing pocket of the verticals. The gaskets should be placed at the

corners of the glazing and then periodically up the vertical. Remove any excess

sealant at the corners of the glazing, on the exterior side, that may ooze out where

the gaskets were butt sealed.

NOTE: The typical glass bite for the I.G. captured system is 1/2”,

except at I.G. heads, where the glass bite is 3/8”. Glass sizes are

based on horizontal D.L.O. plus 1” and vertical D.L.O. plus 7/8”.