CellarPro AIR HANDLER 6500 HORIZONTAL, 7090 User Manual

Page 20

20

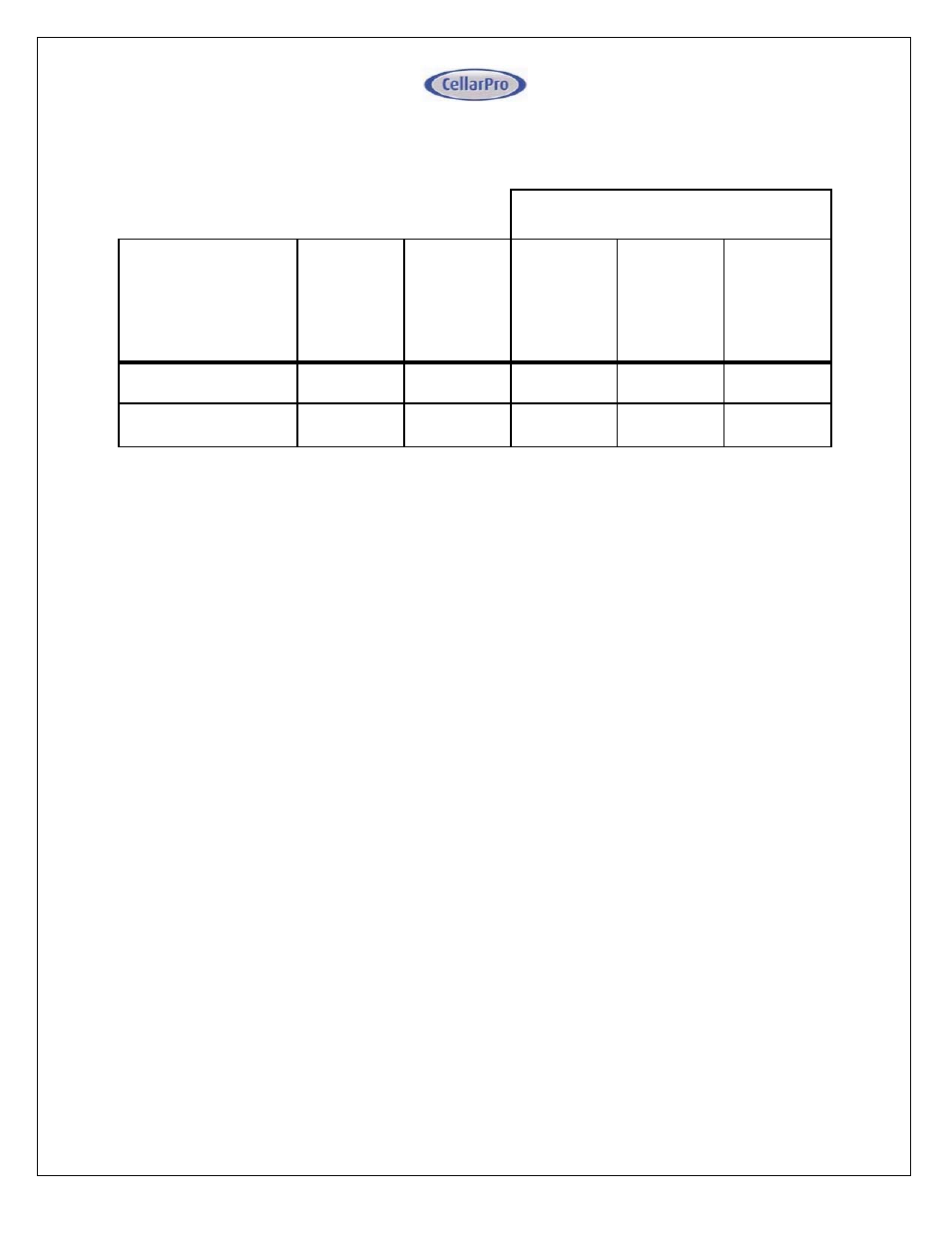

Split System Line Sizing Chart

Suction Line Size by Length ("ODS)

Model

Liquid Line

Size ("ODS)

Up to 100

feet

Minimum

Suction Line

Insulation

Thickness

(in)

Up to 25 feet

Over 25 feet

up to 50 feet

Over 50 feet

up to 100 feet

AH6500S 3/8

1/2

1/2

5/8

5/8

AH8500S 3/8

5/8

5/8

5/8

7/8

Notes:

1) Line lengths are expressed in equivalent feet = actual run length + fitting allowances.

2) Chart includes allowances for Condensing Unit Service Valves, Filter Drier, and Sight Glass.

3) Use only dehydrated refrigeration service tubing and refrigeration grade fittings.

4) Install refrigeration piping in accordance with local codes and ASHRAE guidelines.

Evacuation, Leak Detection, and Charging

Once the piping is installed, the following steps should be performed to ensure a dry

and leak-free system:

1. The Condensing unit is pre-charged with compressor oil. To avoid moisture

contamination of the oil, do not leave the service valves open to atmosphere for

more than 15 minutes.

2. Open the liquid and suction service valves on the condensing unit.

3. Valve Control only: Supply power to the Evaporator only - DO NOT connect

power to the Condensing unit. Turn on the temperature controller, which

will energize and open the liquid line solenoid valve. Verify the solenoid is

powered as indicated by the compressor icon ("snowflake") on the temperature

controller display.

4. Pressurize the system to a maximum of 150PSIG of dry nitrogen. Mark the pressure

and hold for a minimum of 1 hour. If the pressure holds, proceed to the next step,

otherwise locate and repair the leak and repeat this step.

5. Evacuate the system to a minimum of 500 microns. If the vacuum is achieved,

proceed to the next step, otherwise locate and repair the leak and repeat from step 4.