CellarPro AIR HANDLER 6500 HORIZONTAL, 7090 User Manual

Page 19

19

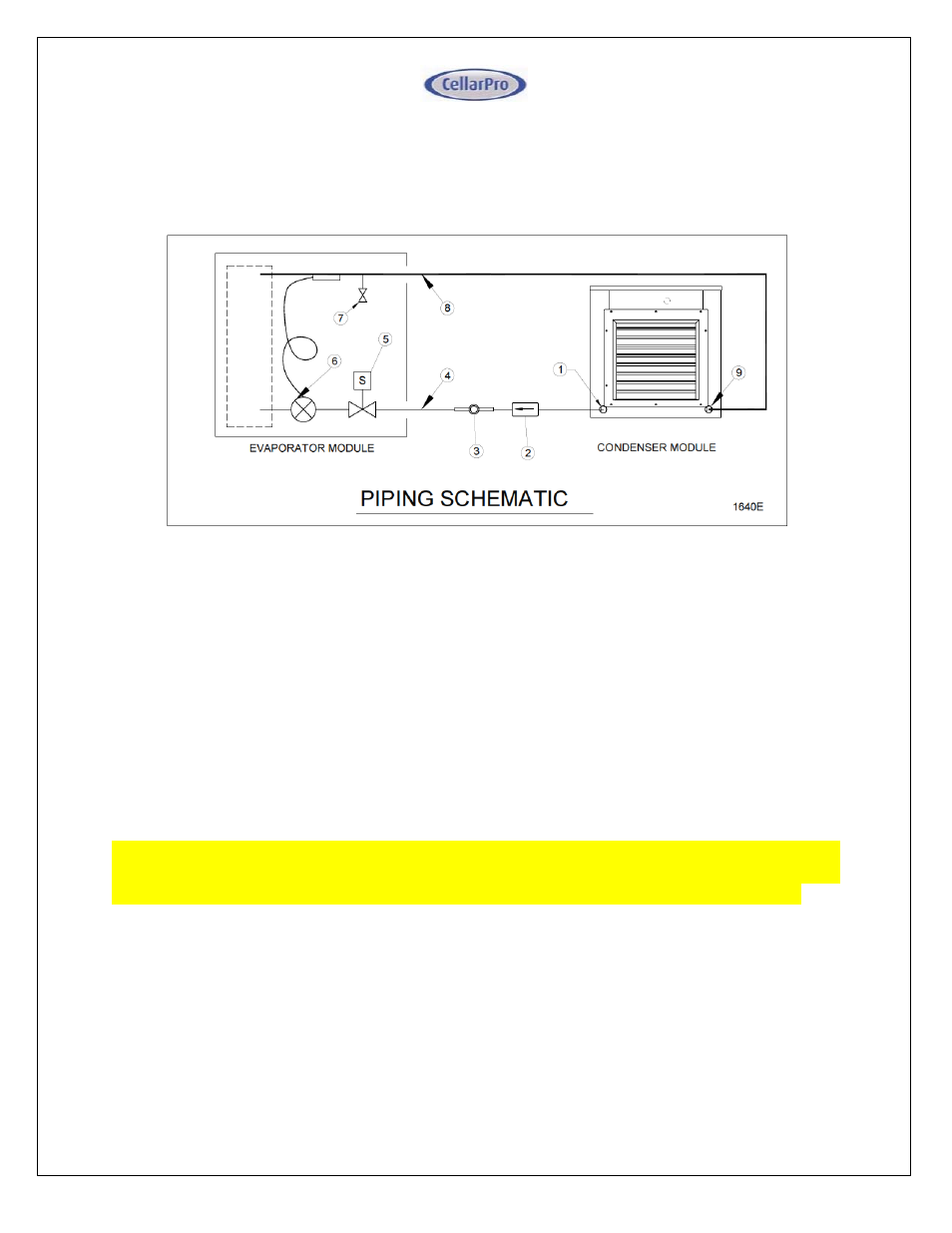

Installing Refrigeration Lines

The Evaporator and Condensing units should be piped according to the following piping

schematic:

Piping Legend

1. The 3/8"ODS liquid service valve located on Condenser Module.

2. Hermetic liquid line filter drier (shipped loose). Install with the directional flow arrow as

shown.

3. Liquid line sight glass with moisture indicator (shipped loose).

4. Liquid line refrigeration piping in accordance with Line Sizing Chart.

5. Factory installed liquid line solenoid valve (normally closed) (Valve Control

configurations only).

6. Factory installed thermostatic expansion valve.

7. Factory installed suction service valve to use for setting expansion valve superheat.

8. Insulated suction line refrigeration piping in accordance with Line Sizing Chart.

9. 5/8"ODS suction service valve located on Condenser Module.

WHEN BRAZING COPPER TUBING TO THE SERVICE VALVES, USE 95/5

SOLDER AND SOLDERING FLUX. DO NOT USE SILVER SOLDER BECAUSE

IT REQUIRES HIGHER HEAT THAT WILL DAMAGE THE SERVICE VALVES.

Line Sizing Chart

Refer to the Line Sizing Chart below for selecting the appropriate tubing size for the

length of the piping run. Note that the recommended line size may not match the

connection ports on the Condensing unit and the Evaporator. Refrigeration grade fittings

must be supplied by the installing technician to make the necessary transitions.

Transitions should be made as close to the unit as possible. Suction line routing

must be designed to ensure oil return to the Condensing unit.