Note – CDI Torque TORQUE WRENCHES Micro-Adjustable Click Type User Manual

Page 30

Page 26

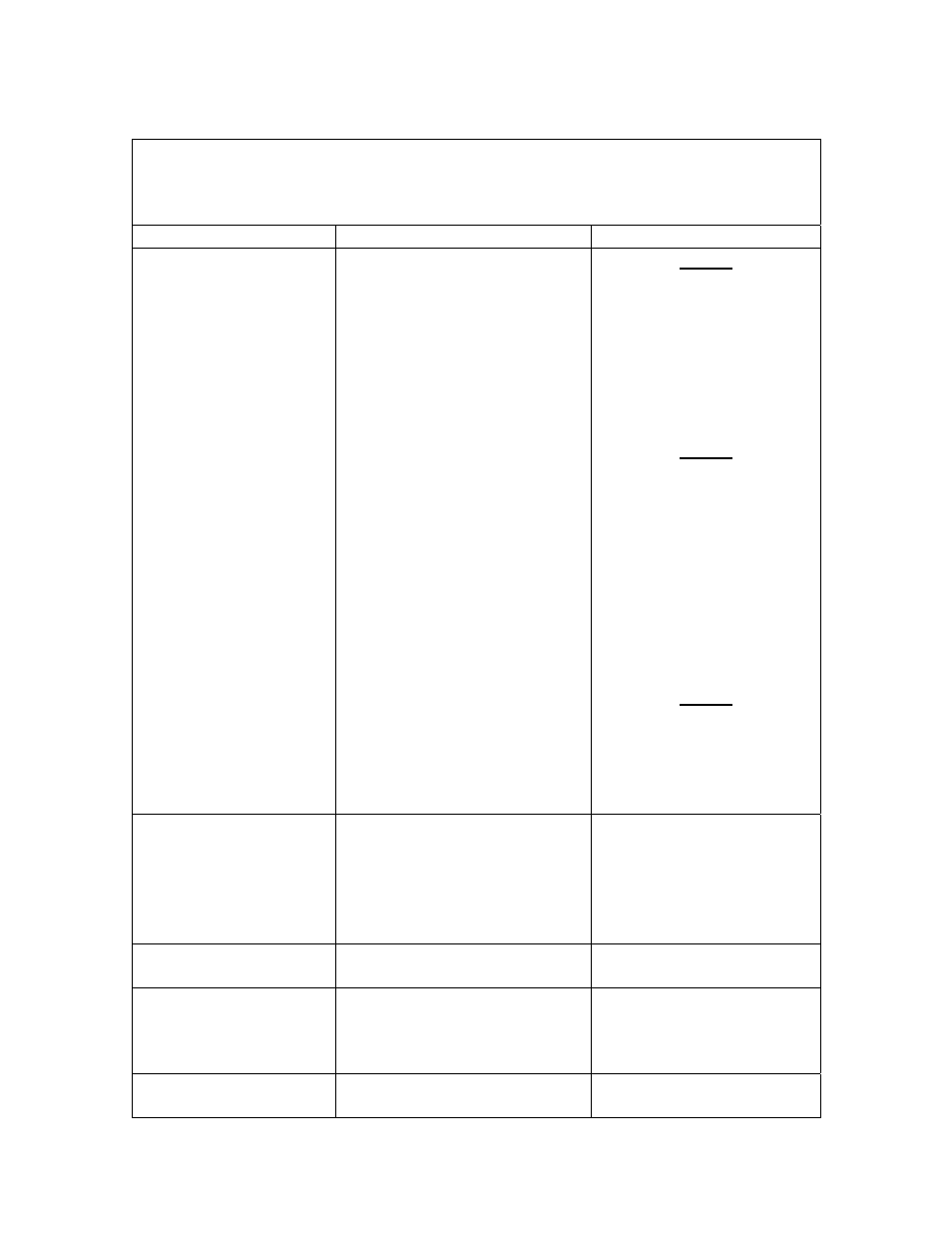

Micrometer Adjustable Torque Wrench

Troubleshooting Matrix

PROBLEM CAUSE(s)

REMEDY

Calibration accuracy at

20% of scale is out of

tolerance.

OR

Calibration accuracy at

20%, 60% and 100% of

scale is out of tolerance.

OR

Calibration accuracy at

60% and 100% of scale

is out of tolerance

Wrench tampered with

(torque seal cracked or

missing)

OR

The handle is unwound

below

the stop point. (torque seal

cracked or missing)

OR

Handle disassembled handle

and reassembled wrong.

(torque seal cracked or

missing)

OR

Pawl and/or pawl slots worn or

damaged.

NOTE

Check handle prior to

adjusting to assure it is

engaged to the adjusting

screw.

Minor calibration

Adjustment.

NOTE

If a minor calibration fails

to bring the 20% of scale

reading into tolerance or if

adjustment causes the 60%

or 100% of scale to fall out

of the tolerance a major

calibration is required.

OR

NOTE

Check pawl and pawl slots

prior to a major calibration.

A major calibration.

When the lock ring is

released the handle goes

up and down the tube

without turning the

handle or the handle

doesn’t turn at all.

The tube insert is stripped

OR

No lubrication on torque load

screw.

Send to authorized repair

facility.

Handle and load screw

disassembled.

See handle/lock ring repair

section to assemble.

Lock Ring Doesn’t

Lock.

The handle was turned without

releasing the lock ring. (the

tube will show groove marks

through the splines)

Send to authorized repair

facility.

Lock ring is jammed or

doesn’t fall into lock

Handle spring problem.

Disassemble the

handle/lock ring and replace