Pre-set torque wrenches, Repair tools required, Pre-set torque wrench – CDI Torque TORQUE WRENCHES Micro-Adjustable Click Type User Manual

Page 28: Note

Page 24

Handle Locking

Torque Wrench Ranges

Hex Flange Nut Size

Torque Ranges

50 in. lb. to 250 in. lb.

3/8”

35 to 40 in. lb.

75 ft. lb. to 1000 ft. lb.

7/16”

90 to 100 in. lb.

8. An accuracy and minor calibration adjustment must be performed after a handle is

assembled.

CALIBRATION INSTRUCTIONS FOR PRE-SET TORQUE WRENCHES

Pre-Set Torque Wrenches

REPAIR TOOLS REQUIRED

1

3/32” “T” Handle hex

1

CDI Adjusting Tool (see chart for correct part number)

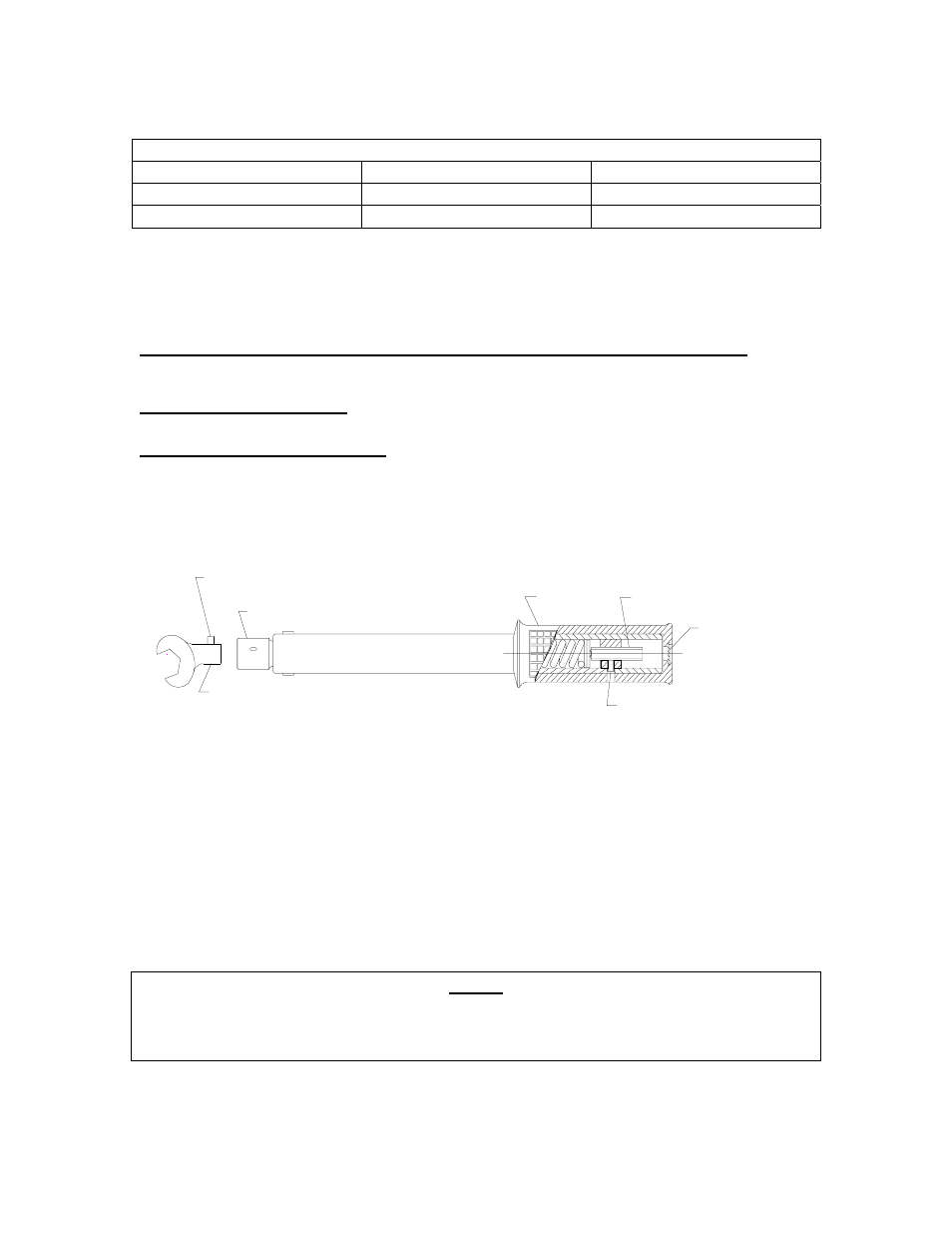

PRE-SET TORQUE WRENCH

1. Loosen locking screw (1) with the 3/32” T handled hex.

2. Remove Button Plug (2) from rubber handle end by bending a corner of the handle

end until the edge of the plug appears. Then remove the plug by lifting the edge.

3. Insert the interchangeable head (5) into the wrench receptacle until the locking pin (6)

is fully engaged with the corresponding receptacle hole (3).

NOTE

Some heads used in pre-set torque wrenches have lengths that vary. It is recommended

that pre-set torque wrenches be calibrated with the head that is to be used to assure the

greatest accuracy in calibration.

LOCKING SCREW (1)

ADJUSTING SCREW (4)

HAND GRIP

BUTTON

PLUG (2)

RECEPTACLE (3)

INTERCHANGEA

BLE HEAD (5)

LOCKING

PIN (6)