Major calibration and repair – CDI Torque TORQUE WRENCHES Micro-Adjustable Click Type User Manual

Page 12

Page 8

9. Pull the lock ring down, while applying a light force towards the wrench (to prevent

handle disengagement) and turn handle until handle “0” mark is aligned to the

centerline of the scale.

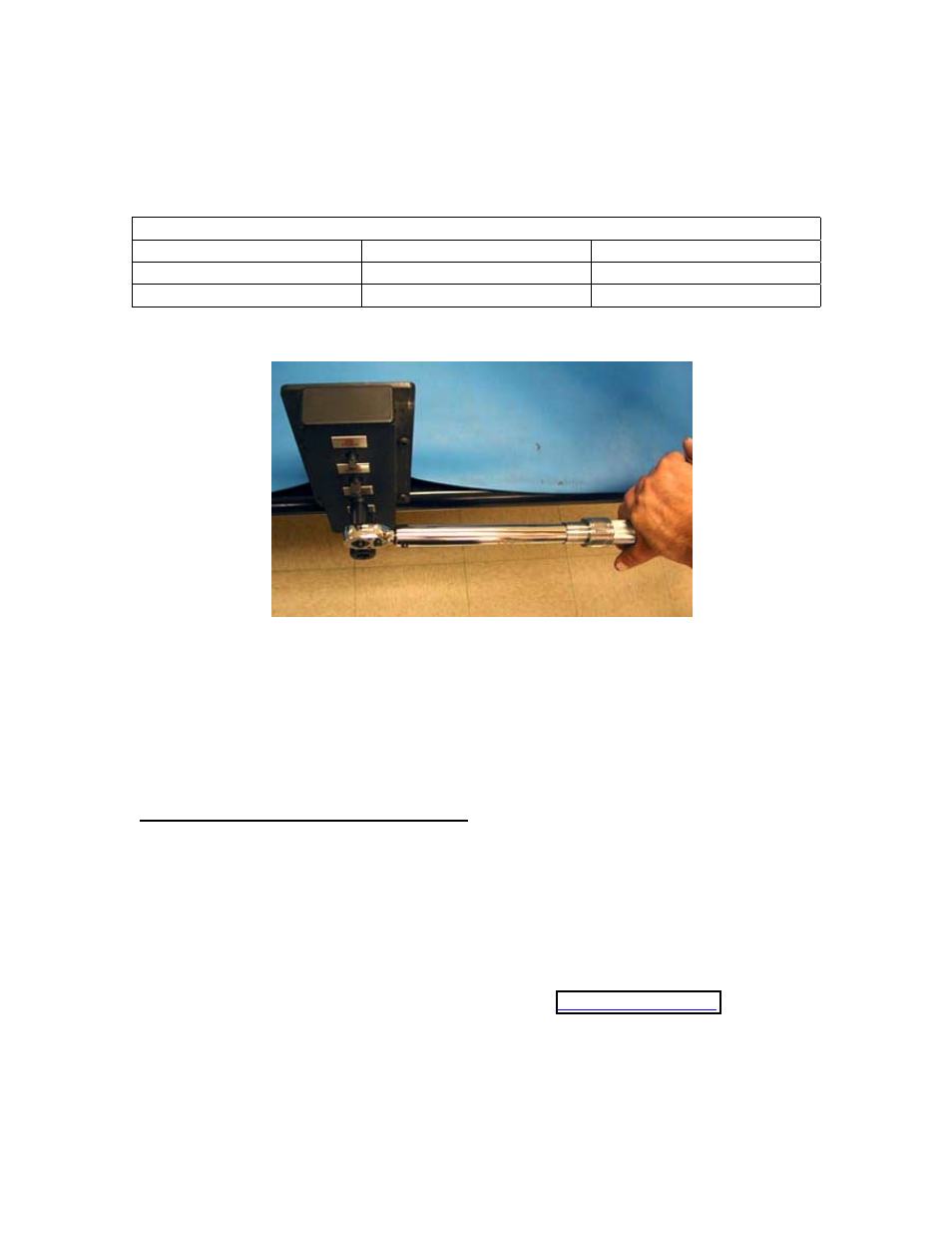

10. Tighten the hex flange nut (B) with a 200 in. lb. torque wrench as follows:

Handle Locking

Torque Wrench Ranges

Hex Flange Nut Size

Torque Ranges

50 in. lb. to 250 in. lb.

3/8”

35 to 40 in. lb.

75 ft. lb. to 1000 ft. lb.

7/16”

90 to100 in. lb.

11. Retest the wrench for accuracy (steps 1 through 4). If the wrench is not within

specified accuracy requirements repeat steps 5 through 10 or the wrench may require

a major calibration.

MAJOR CALIBRATION AND REPAIR

These instructions are to be used for the major calibration. Major calibration requires the

wrench to be partially disassembled from the front removing the ratchet or drive

mechanism, to inspect the internal component parts for contaminates, damage and/or

wear. Replacement parts are normally required. Each wrench model has an Exploded

Illustration that lists the component parts and shows assembly particulars. The exploded

illustration must be used as a guide for purchasing CDI Torque Wrench component parts.

Contact CDI Sales Department at (626) 965-0668 or

for

Exploded Illustrations for a particular torque wrench model and/or to purchase

component parts needed for repairs.