Example #2, Pawl selection chart, Size & orientation – CDI Torque TORQUE WRENCHES Micro-Adjustable Click Type User Manual

Page 18

Page 14

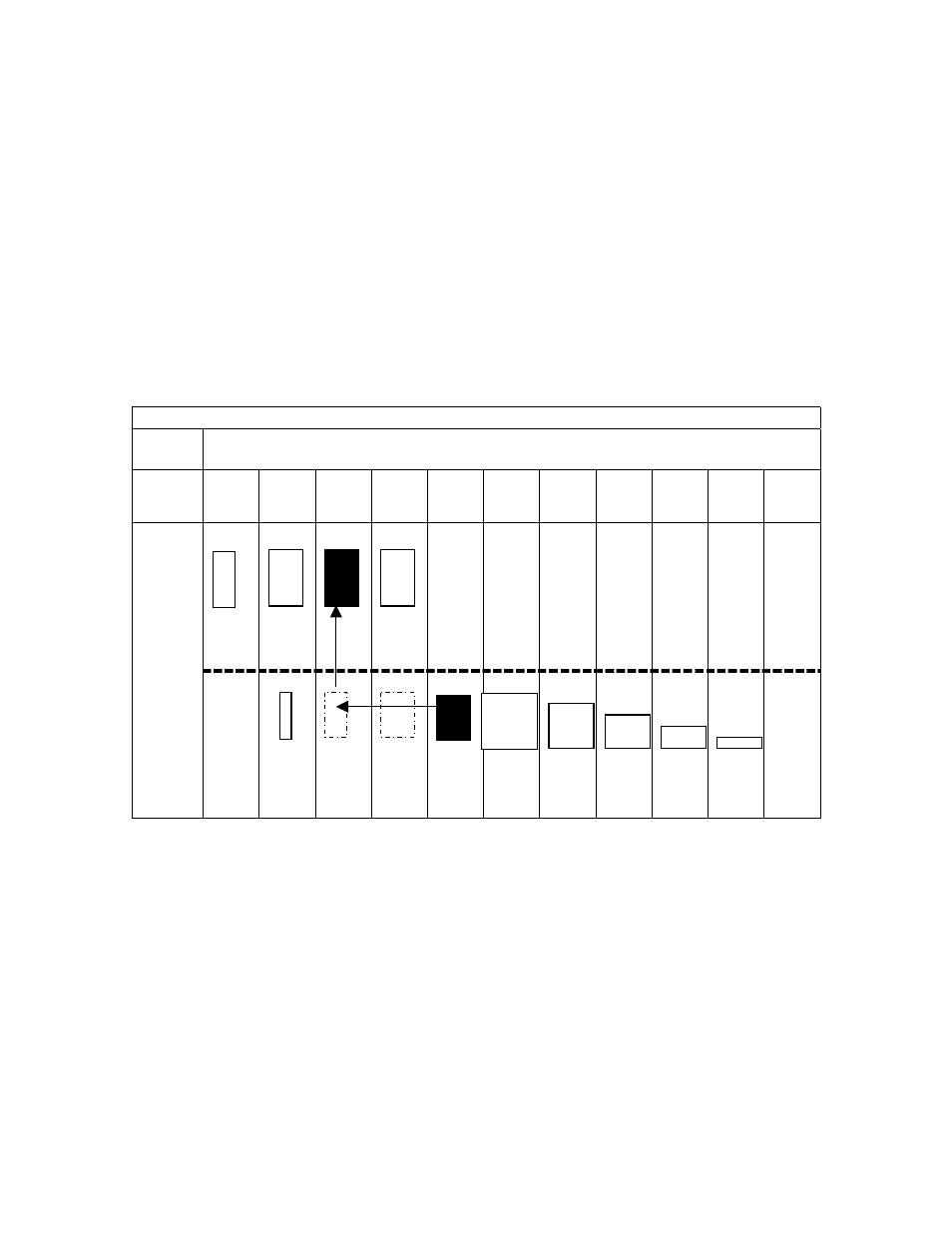

EXAMPLE #2

The wrench reads approximately 5% high from nominal. Disassemble the wrench and

measure the pawl. It was .250 (6.35)

⇓

X .244 (6.20)

⇔

, orientated with the longer side of

the pawl perpendicular to the cam slot. To find the correct pawl, locate the pawl removed

from the wrench on the pawl selection chart. This pawl number is 1TA on the chart. This

is the starting point for selecting a new pawl.

To decrease the reading of the wrench 4% choose the pawl two places to the left of 1TB

(.250 (6.35)

⇓

X .244 (6.20)

⇔

) which is 3TA (.260 (6.60)

⇓

X .245 (6.20)

⇔

) or 3TB

(.250 (6.35)

⇓

X .235 (6.00)

⇔

).

The recommended change would be to a Style “A”, if available. This pawl change should

decrease the wrench reading to within approximately 1% of nominal.

4. Check the pawl and pawl slot for worn or damaged edges. Choose the appropriate

pawl to increase

⇒

or decrease

⇐

the

reading.

5. Go to page 15 and follow instructions 4 through 9 to calibrate.

OR

6. To disassemble, clean, inspect and re-lubricate go to page 14 and follow instructions

1 though 9.

PAWL SELECTION CHART

STYLE

SIZE & ORIENTATION

Metric sizes (mm) are in parentheses ().

♦

♦

♦

♦

5T

4T

3T

2T

1T

0

1S

2S

3S

4S

5S

A

.260

(6.60)

or

A

⇓⇓⇓⇓

.235

(6.00)

⇔

⇔

⇔

⇔

A

⇓⇓⇓⇓

.240

(6.10)

⇔

⇔

⇔

⇔

A

⇓⇓⇓⇓

✷

✷

✷

✷

✷

✷

✷

✷

.245

(6.20)

⇔

⇔

⇔

⇔

A

⇓⇓⇓⇓

.250

(6.35)

⇔

⇔

⇔

⇔

B

.250

(6.35)

B

⇓⇓⇓⇓

.230

(5.85)

⇔

⇔

⇔

⇔

B

⇓⇓⇓⇓

.235

(6.00)

⇔

⇔

⇔

⇔

B

⇓⇓⇓⇓

.240

(6.10)

⇔

⇔

⇔

⇔

B

⇓⇓⇓⇓

.244

(6.20)

⇔

⇔

⇔

⇔

B

⇓⇓⇓⇓

B

⇔

⇔

⇔

⇔

.244

⇓⇓⇓⇓

(6.20)

B

⇔

⇔

⇔

⇔

.240

⇓⇓⇓⇓

(6.10)

B

⇔

⇔

⇔

⇔

.235

⇓⇓⇓⇓

(6.00)

B

⇔

⇔

⇔

⇔

.230

⇓⇓⇓⇓

(5.85)

B

⇔

⇔

⇔

⇔