Torque ranges, Troubleshooting – CDI Torque TORQUE WRENCHES Micro-Adjustable Click Type User Manual

Page 29

Page 25

4. Place the wrench on a torque tester and turn adjustment screw (4) with a T handled

hex ( 1/8” or 3/32”) until the desired setting is on the torque tester when a load is

applied.

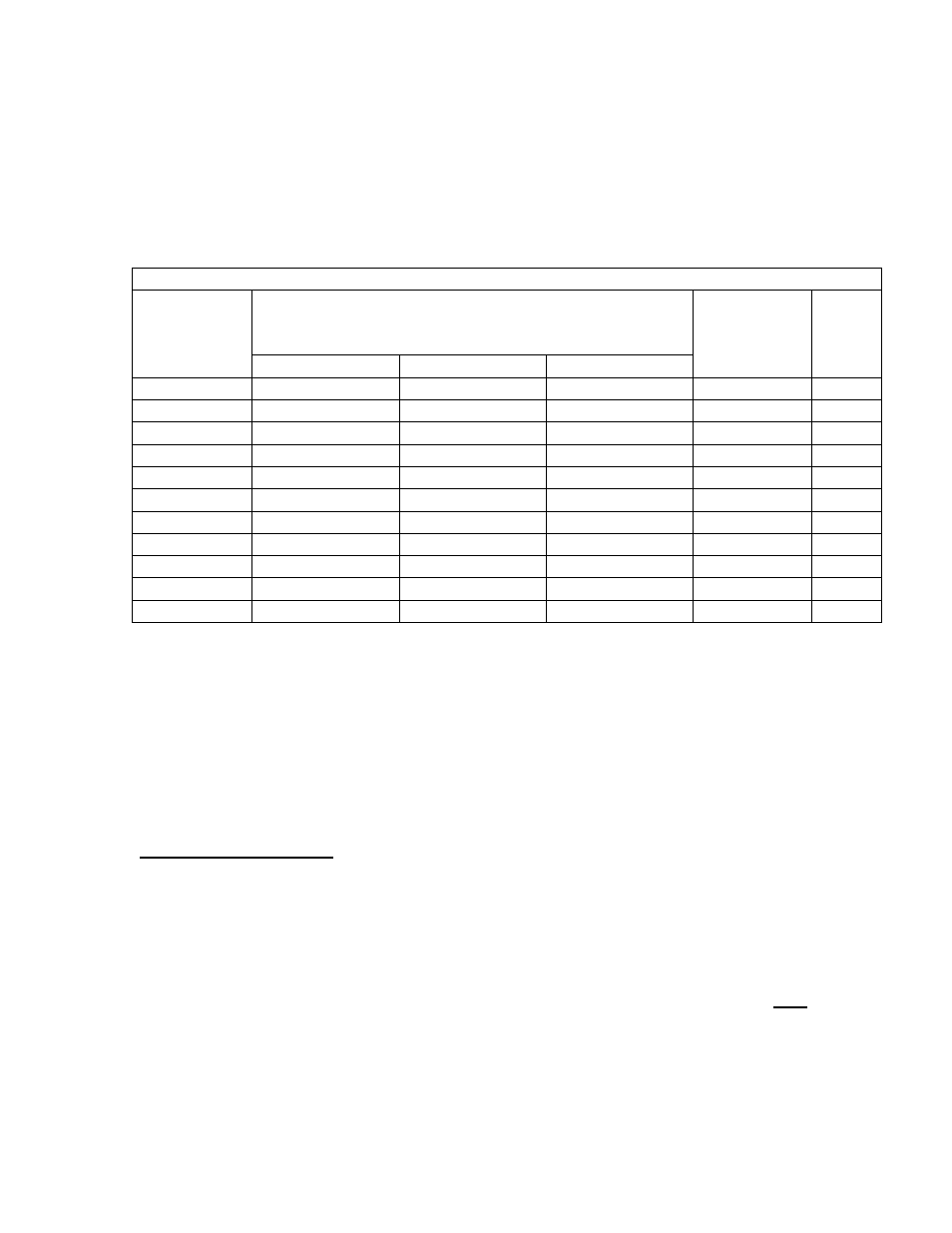

CDI Pre-Set (Click) Torque Wrench Ranges & Adjustment Tool Part Numbers

Torque Ranges

Adjustment

Tool

Part #

Hex

Size

Part

Number

in./ft. lb.

dNM/NM.

cmkg/mkg

5T-I

16-60 in. lb.

14-67 dNM

14-69 cmkg

600-45-01

3/32”

10T-I

36-108 in. lb.

40-122 dNM

42-124 cmkg

600-45-02

1/8”

10ST-I

84-300 in. lb.

95-338 dNM

110-385 cmkg

600-45-02

1/8”

10AT-I

84-300 in. lb.

95-338 dNM

110-385 cmkg

600-45-03

1/8”

50ST-I

10-50 ft. lb.

14-67 NM.

1.4-7 mkg.

600-45-03

1/8”

50T-I

10-50 ft. lb.

14-67 NM.

1.4-7 mkg.

600-45-03

1/8”

100ST-I

30-150 ft. lb.

41-200 NM.

4.1-20 mkg.

600-45-04

1/8”

100T-I

30-150 ft. lb.

41-200 NM.

4.1-20 mkg.

600-45-04

1/8”

200T-I

40-200 ft. lb.

55-270 NM.

5.5-27 mkg.

600-45-04

1/8”

300T-I

60-300 ft. lb.

82-400 NM.

8.2-40 mkg.

600-45-05

3/16”

600T-I

200-600 ft. lb.

275-800 NM.

27.5-135 mkg.

600-45-06

3/16”

5. Tighten the locking screw (1). Test wrenches setting three more times. If the readings

are correct, place torque seal into the locking screw (1) hex opening to prevent

tampering.

6. Place button plug (2) back into the handle end by inserting it into one side of the

opening then applying pressure with your finger until it is fully engaged.

TROUBLESHOOTING

The Pre-Set Torque Wrenches generally do not require repair. They are sent in for

calibration to the required use setting with the head or adapter chosen for use. All

adjustments are to be made as shown in the section on Pre-Set Torque Wrench

Calibration.

The Troubleshooting Matrix is for the Micrometer Adjustable Wrench models only.

Refer to the Troubleshooting Matrix for problems that could occur to the Micrometer

Adjustable Torque Wrenches and their remedy.