Note, Diagram 4 – Arc Machines 415 WDR User Manual

Page 40

Model 415

Operation Manual

5.7

ARC VOLTAGE CONTROL (AVC) CALIBRATION

NOTE

A weld schedule is required for the following calibration. The first time a calibration is done it will be

necessary to CREATE a Calibration Weld Schedule. This section will outline all pertinent schedule

elements needed. (Pass 2)

1.

Insure that a Weld Head with AVC is connected per section III of the M415 Operation Manual.

NOTE

A weld schedule is required for the following calibration. The first time a calibration is done it will be

necessary to CREATE a Calibration Weld Schedule. This section will outline all pertinent schedule

elements needed. (Pass 2)

2.

Insure that a Weld Head with AVC is connected per section III of the M415 Operation Manual.

3.

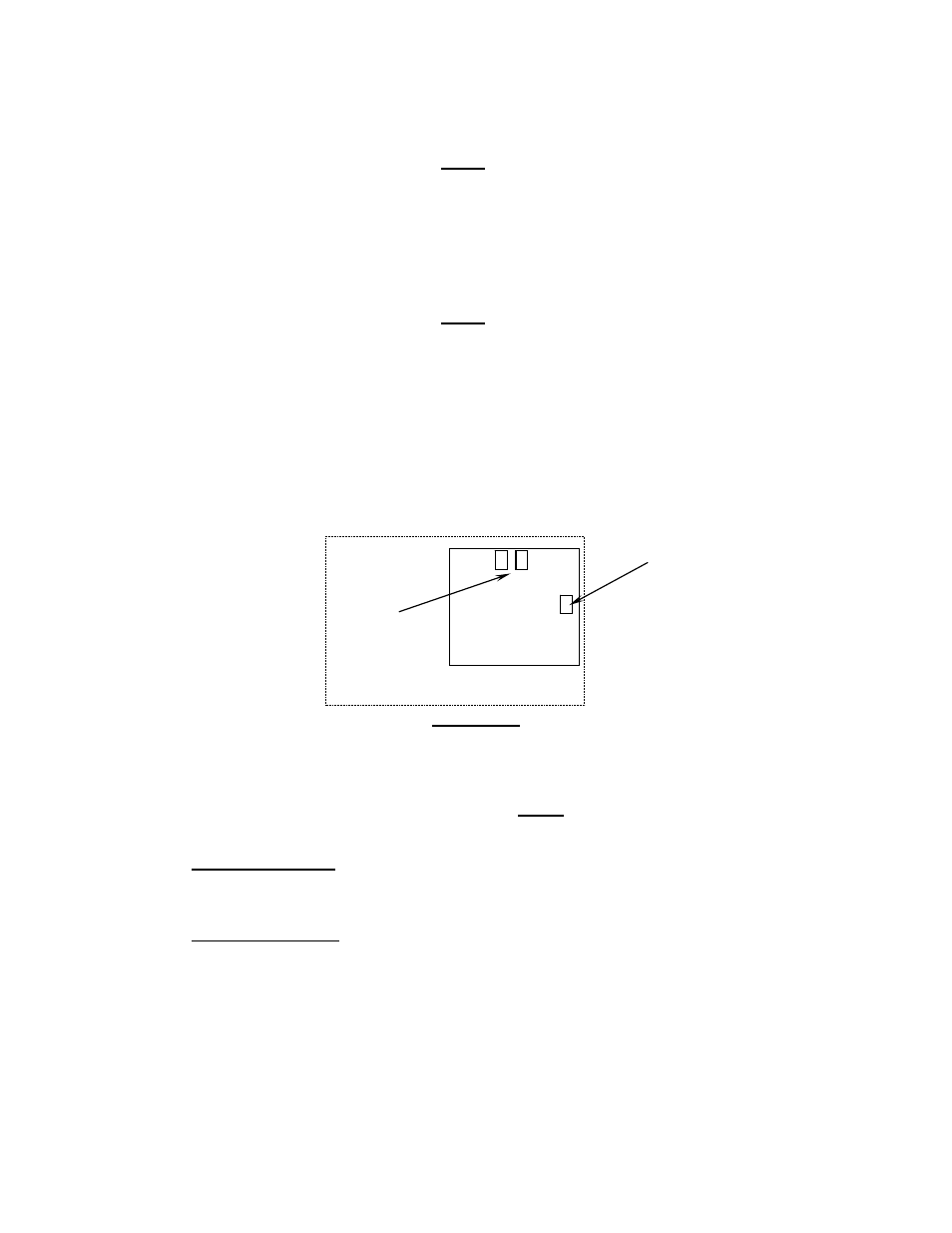

The AVC Calibration is done on the AVC / OSC PCB (P/N 13D150313-01) located on the Servo

PCB mounting plate in labeled slot B 0/1. Locate the AVC adjustment trim pot R-40 on the

PCB (diagram 4). DO NOT ADJUST TRIM POTS R-80 AND R-81 (these are factory calibrated

for use with special application weld heads or fixtures not discussed in this section).

R-40

R-80 & R-81

DIAGRAM 4

4.

To calibrate the AVC the user will need to have a Weld Schedule in the Library for the M-415

and applicable Weld Head, (Pass 2).

5.

The AVC calibration schedule will be run in the WELD Mode and will contain the following:

Onelevel Functions

Prepurge

010

Torch Gas Rate

20

Upslope

01.0

Start Level

25

AVC Start Delay

1.0

Num Starts

1

Level

Advance

Manual

Postpurge

010

Stubout Mode

On

Downslope

05.0

Start Mode

Touch

AVC Stop Delay

1.0

AVC Resp

15**

Osc

Mode

OFF

**Note: For M-415 Software Revisions prior to Rev. 1.43, use an AVC Response of five (5) in

place of the pictured AVC Resp 15.

Document No. 740084

Revision N

35