Service and maintenance – Craftsman 247.28933 User Manual

Page 28

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND MAINTENANCE

Applying force to either the timing belt idler pulley or the timing 9.

belt idler bracket, pivot and hold the idler bracket against the

spring tension just tar enough to allow lifting the timing belt off

and above the idler pulley. Carefully release the idler bracket. See

Figure 21.

10

.

Loop the timing belt and lift out of the timing pulley and over the

right hand spindle assembly. Maneuver the belt between the drive

11

,

pulley on top of the spindle assembly and the spindle cover to

remove.

-|

2

_

Repeat the above procedure to remove the belt from the left hand

spindle assembly timing pulley. Refer to Figure 21.

Loop the new timing belt and maneuver the belt between the drive

pulley on top of the right hand spindle assembly and the spindle

13

,

cover. Lower the belt until loosely around the right hand timing

pulley. Refer to Figure 21.

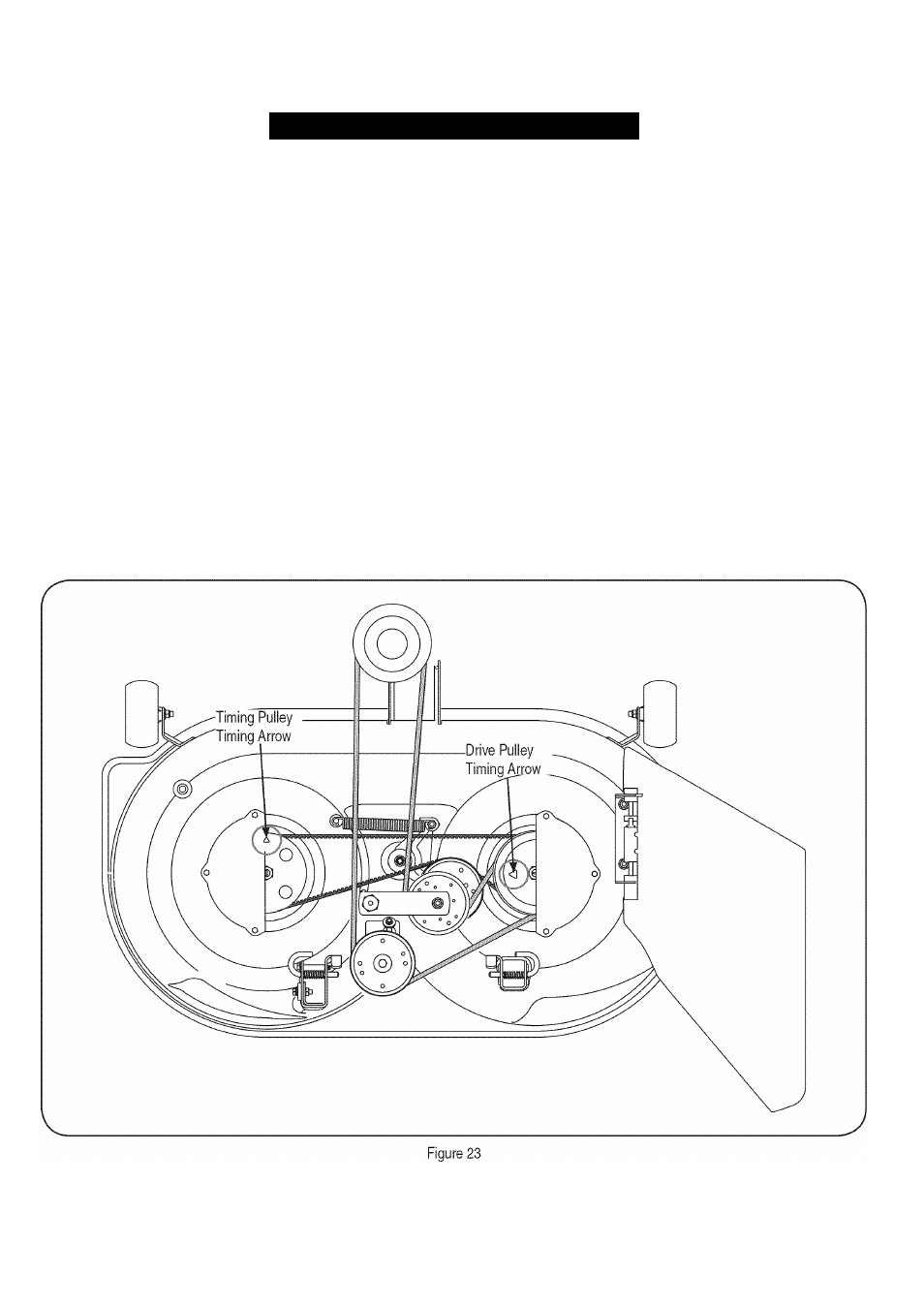

Note the arrows on the top of the timing pulley on the LH spindle

and on the drive pulley of the RH spindle assembly. These timing

arrows MUST be positioned 90° from each other as shown in

14

,

Figure 23.

Rotate the RH spindle assembly to position the drive pulley timing

arrow as shown in Figure 19. Then without moving the RH drive

pulley, pull the timing belt tight against the RH timing pulley, above

the timing belt idler pulley, and over to the LH timing pulley.

Turn the LH timing pulley so that its timing arrow is 90° from the

RH spindle assembly timing arrow. Refer to Figure 23.

While making sure not to change the position of either pulley, loop

the timing belt over the LH timing pulley.

After making sure the spring is hooked onto the idler bracket and

screw, pivot the timing idler bracket/idler pulley against the spring

tension just far enough to allow you to lower the backside of the

timing belt onto the idler pulley. See Figure 23.

Re-check the timing arrows on the two pulleys. If they have

moved from the 90° position when tensioning the timing belt, pivot

the idler pulley to relieve tension on the belt and re-position the

pulleys. The timing arrows MUST be positioned 90° from each

other as shown in Figure 23.

Re-install the idler bracket backstop components as originally

installed in the deck housing, and position so that there is a

1

/

8

”

gap between the backstop and idler bracket. Tighten the hex

screw and flange lock nut to secure in the adjusted position.

28