Product specifications, Snow thrower, As required – Craftsman 536.886260 User Manual

Page 18: Lubrication-every 25 hours, To lubricate, Maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

MAINTENANCE

PRODUCT SPECIFICATIONS

HORSEPOWER

9 HP

DISPLACEMENT

19.34 cu. in.

GASOLINE

CAPACITY

4 quarts

(unleaded)

OIL CAPACITY

(20 oz capacity)

5W30

SPARK PLUG:

Champion RJ19LM

(Gap .030 in.) or

equivalent

VALVE CLEARANCE: Intake: .010 In.

Exhaust; .010 In.

SNOW THROWER

AS REQUIRED

The following adjustment should be

preformed more than once each sea

son.

1. Auger drive belt should be adjusted

after the first 2 to 4 hours of use,

again about mid-season and twice

each season thereafter

(See to Ad

just Belts paragraph in the Ser

vice and Adjustment section).

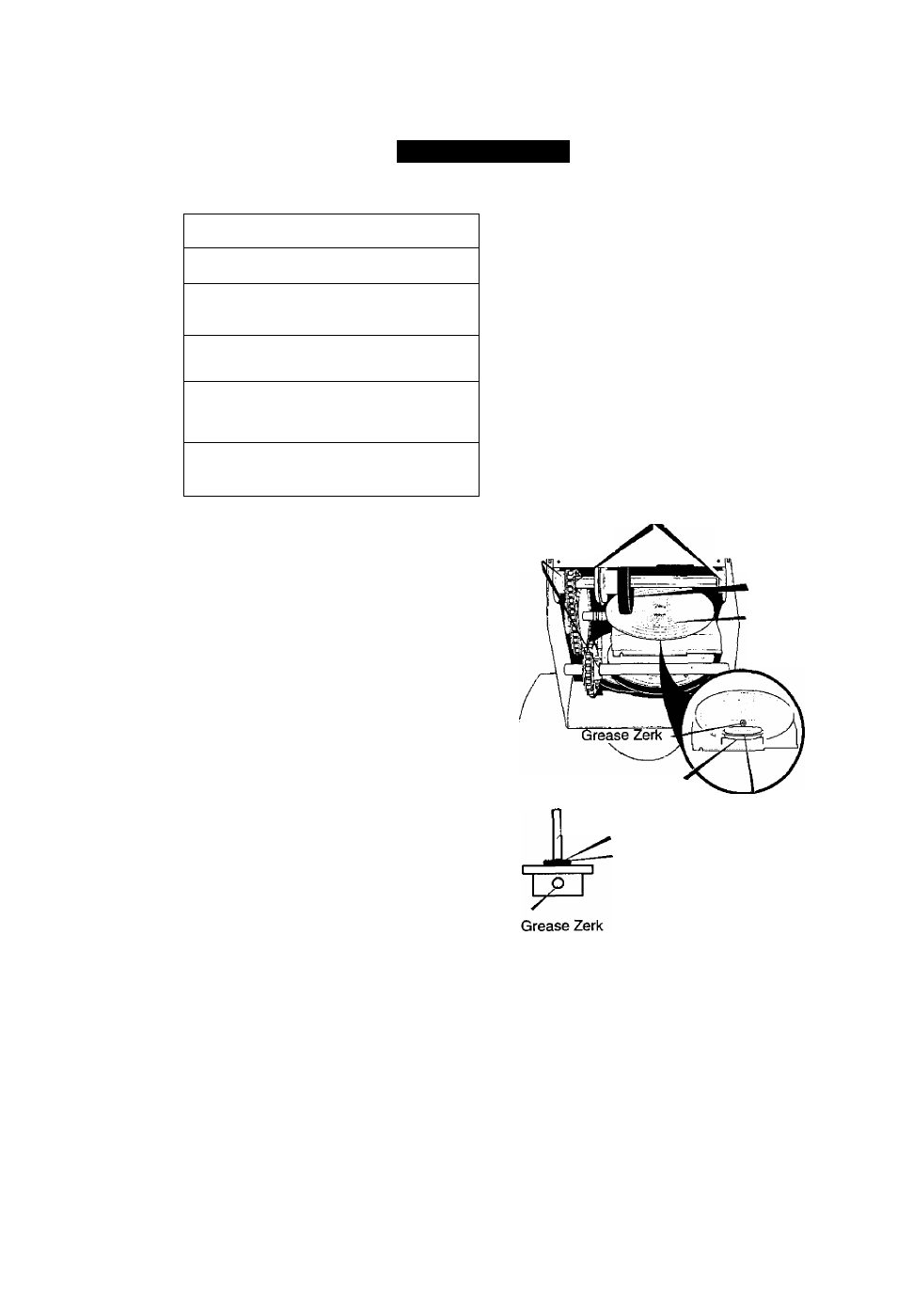

LUBRICATION-EVERY 25 HOURS

Lubricate Disc Drive Plate every

twenty-five (25) hours and at the end of

the season and/or before storage.

To Lubricate

1. Position speed selector lever in first

gear.

Stand the snow thrower up on the

auger housing end.

Remove the bottom panel.

Turn

disc drive plate

clockwise by

hand until

grease zerk

is clearly

visible at front center. See

Figure 16.

Place a

coin

or

(a shim of equal

thickness)

between the rubber

fric

tion wheel

and

disc drive plate

to

F-001088J

2

.

3.

4.

5.

prevent rubber friction wheel con

tacting the

drive disc plate.

6. To

grease zerk,

use a hand grease

gun, lubricate with a Hi Temp EP

Moly grease. Fill zerk only until

grease becomes visible below bear

ing assembly located under grease

zerk.

DO NOT

over fill.

CAUTION: DO NOT

allow grease to

come in contract with the

disc drive

plate

or

friction wheel

or damage will

result.

IMPORTANT:

Remove

coin

and en

sure that a gap exists between

friction

wheei

and

disc drive plate.

NOTE:

Clean all excess grease found

on friction disc hub.

Sprockets Hex Shaft and Sprockets

(Require No

Lubrication

Friction

Wheel

Disc

Drive

Plate

Friction

Wheel

Coin or Shim

Bearing

Poirtlt»hich

grease should

be visible

Gap Between

Friction Wheel

and Disc Drive

Plate

Figure 16

LUBRiCATION-NOT REQUIRED

1. Hex Shaft and Sprockets - Hex

shaft and sprockets

require no lu

brication. All bearings and bushings

are lifetime lubricated and require

no maintenance. See Figure 16.

NOTE: Any greasing or oiling of the

above components can cause contami

nation of the friction wheei. If the disc

18