Hang opener chassis, Attach emergency release rope ^ handle, Installation – Craftsman 139.535006 User Manual

Page 13: Steps, Step 6

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

Installation

STEPS

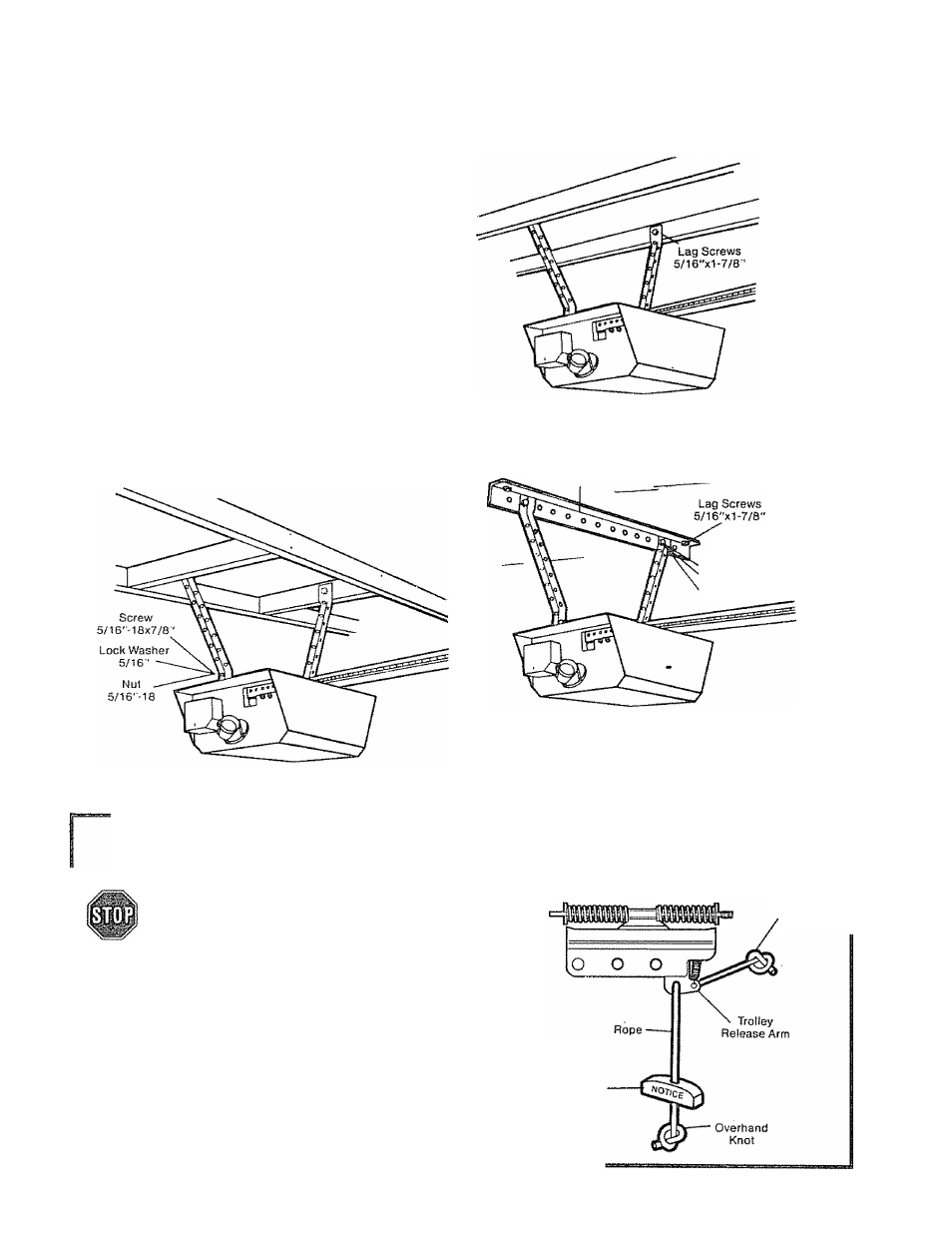

Hang Opener Chassis

THE OPENER CHASSIS MUST BE ATTACHED TO A

STRUCTURAL SUPPORT OF THE GARAGE, Three

representative installations are shown. Yours may be

different Hanging brackets should be angled to pro

vide rigid support

PROCEDURE: On EACH side of opener measure

the distance from chassis to structural support

Cut both pieces of the hanging bracket to required

lengths. Flatten one end of each bracket and bend or

twist to fit fastening angles, DO NOT BEND AT BRAC

KET HOLES Drill 3/16" pilot holes in structural sup

port Fasten flattened ends of brackets to support

as shown.

Lift opener and fasten to hanging bracket as shown.

Checkto make sureTee rail is centered overdoor

bracket. Close the garage door. If door hits rail,

raise header bracket. REMOVE 2x4.

Grease rail surfaces on which trolley slides. A tube of

grease is supplied.

Bracket

(Not Supplied)

Finished

Ceiling

(Not Suppiied)

5/16'’-tax7/8" Screw

5/16" Lock Washer

5/16"-18 Nut

STEP 6

Attach Emergency Release Rope ^ Handle

USE EMERGENCY RELEASE ONLY TO DIS

ENGAGE TROLLEY. DO NOT USE RED

EMERGENCY RELEASE ROPE AND HAN

DLE TO PULL DOOR OPEN OR CLOSED.

PROCEDURE: Thread one end of rope through hole

in top of red handle so 'NOTICE' reads right side up

as shown. Secure with an overhand knot NOTE: Knot

should be at least 1 inch from end of rope to pre

vent slipping. Thread other end of rope through

hole in release arm of outer trolley. Adjust rope length

so that handle is 6 feet above the floor. Secure with

an overhand knot as above.

NOTE: If it is necessary to cut rope, heat seal cut

end with a match or lighter to prevent fraying

and/or raveling.

Overhand

Knot

Emergency

Release Handle

13