Troubleshooting – Craftsman 919.678250 User Manual

Page 31

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

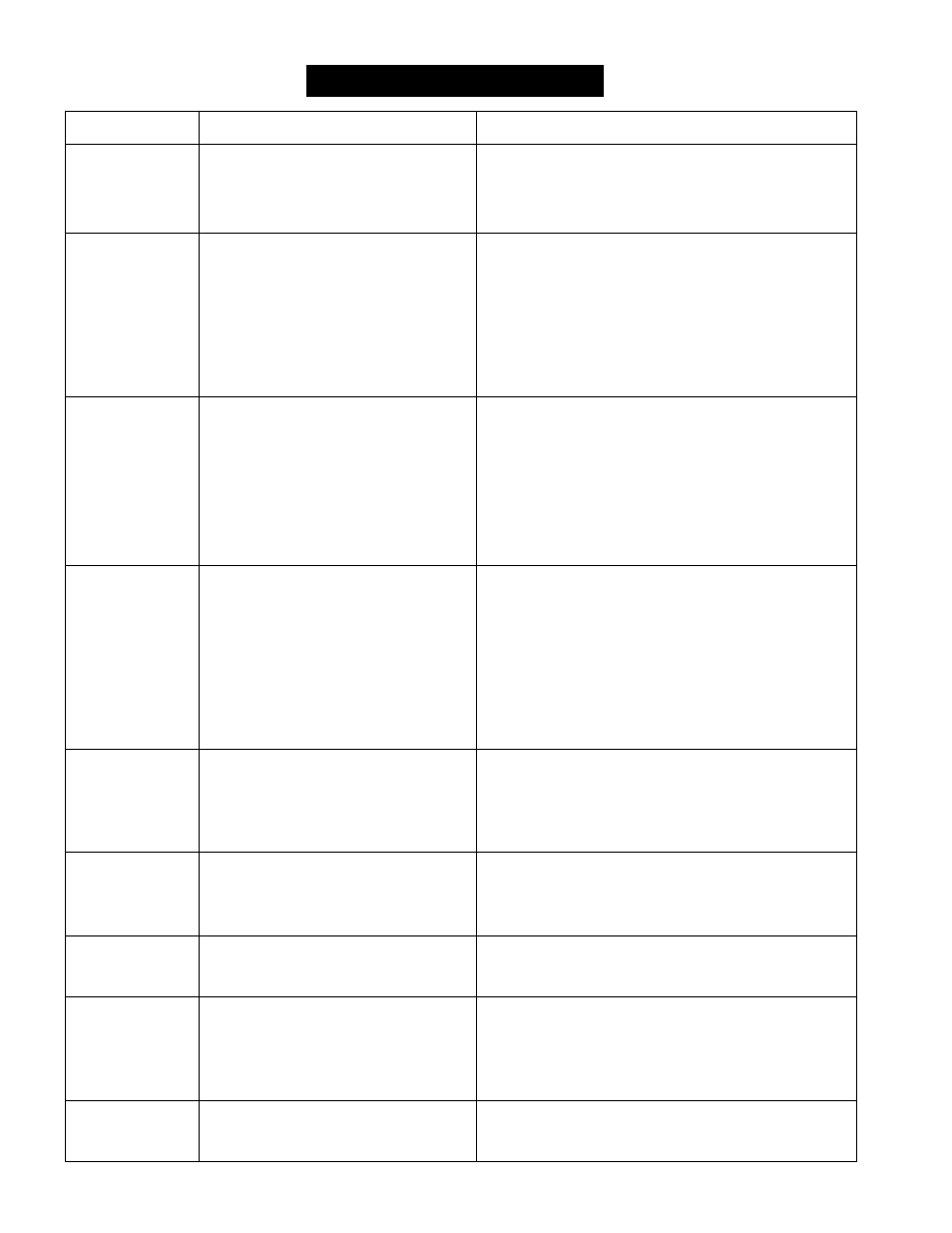

TROUBLESHOOTING

SYMPTOM

CAUSE

SOLUTION

Engine won’t

1. Engine throttle is in "OFF" Position.

1. Slide throttle to "Rabbit" position.

start

2. Choke iever has not been piaced to

choke.

2. Slide choke lever to choke position.

3. Pressure buildup after initial use.

3. Depress trigger gun.

Won’t Draw

1. Nozzle not in chemical draw position.

1. Place nozzle to low pressure.

Chemical

2. Chemicai screen is obstructed.

2. Check chemical screen; clean if obstructed.

3. Chemical screen not working.

3. Make sure chemical screen is submerged in

chemical/water.

4. Chemicai injector orifice obstructed

or stuck.

4. Check and clean.

5. Chemicai injector ciosed.

5. Open chemical injector by turning adjustment

knob.

Pump running

normaliy but

pressure does

1. Water suppiy restricted.

1. Check water supply and filter screen for.

blockage. Check hoses for blockage, kinks,

leaks, etc.

not achieve

rated vaiues

2. Nozzie is in iow PSl position.

2. Twist nozzle at end of wand clockwise the high

pressure position.

3. Nozzie incorrect or worn.

3. Check and replace.

4. Pump sucking air.

4. Check that hoses and fittings are air-tight.

5. Nozzie blocked.

5. Clean nozzle.

Fluctuating

Pressure

1. Pump sucking air.

1. Check that hoses and fittings are air tight. Purge air

from garden hose.

2. Garden hose inlet strainer ciogged.

2. Clean. Check filter frequently.

3. Worn Seáis or Packing.

3. Check and replace.

4. Inadequate water supply.

4. Check hose for kinks.

5. Fouled or dirty iniet or discharge

vaives.

5. Check flow available to pump. Check for

excessive heat, 145° F or above.

6. Leaky discharge hose.

6. Clean inlet and discharge valve assemblies.

Replace if damaged.

Pressure drops

after period of

1. Nozzie clogged, partially obstructed.

1. Use nozzle cleaning kit to clear obstruction. (See

Nozzle Maintenance under Service Adjustment.)

normai use

2. Nozzle worn.

2. Clean or replace.

3. Pump Valves worn, dirty or stuck.

3. Check and replace.

4. Worn pump piston packing.

4. Check and replace.

Pump noisy

1. Water too hot.

1. Reduce temperature below 63° C or 145° F.

2, Pump sucking air.

2. Check that hoses and fittings are air tight.

3. Valves dirty or worn.

3. Check, clean or replace.

4. Worn bearings.

4. Check and replace if necessary.

Presence of

1. High humidity.

1. Change Oil.

water in oii (oii

milky).

2. Piston packing and oii seal worn.

2. Check and replace oil seals.

Water dripping

1. Thermal relief functioning normal.

1. Protecting pump, if not using pressure washer for

from pump

2. Fittings Loose.

a long period of time, shutoff engine.

3. 0-rings of piston guide or retainer

2. Tighten.

worn.

3. Check and replace.

4. Piston packing worn.

4. Check and replace.

Oil Dripping

1. Oil seal worn

1. Check and replace

2. Loose drain plug or worn drain plug

o-ring.

2. Tighten drain plug or replace O-ring. Do not overtorque.

16