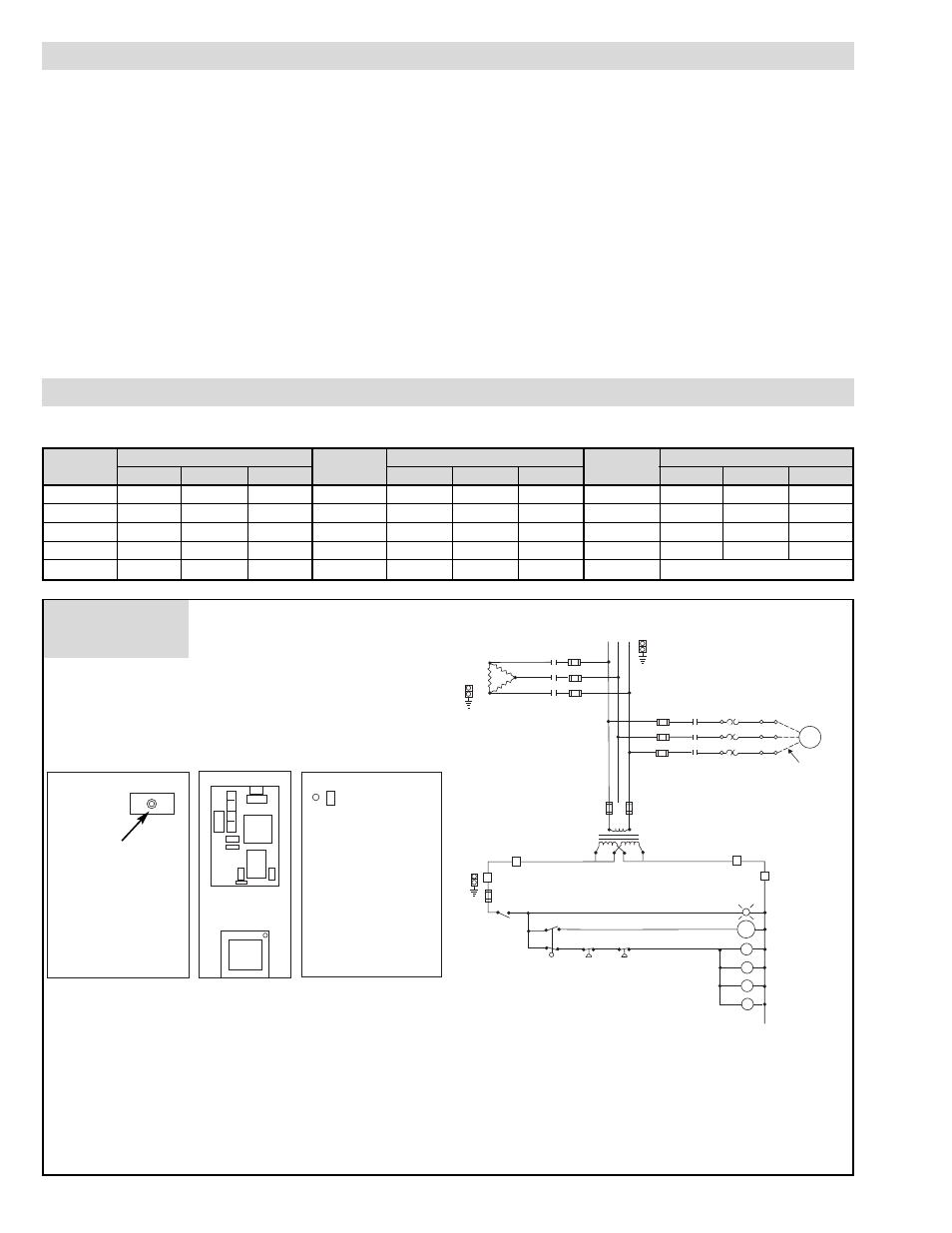

Wiring typical wiring diagrams, Diagram 1, 3 phase voltage – Chromalox CHPES-6A User Manual

Page 4: Boilers under 40 amps total (not fused)

Diagram 1

3 Phase Voltage

3 Phase Voltage

3 Phase Voltage

Boiler

208

240

480

Boiler

208

240

480

Boiler

208

240

480

WIRING

TYPICAL WIRING DIAGRAMS

WARNING: Hazard of Shock. Disconnect all power

before working on boiler. Boilers must be effectively

grounded in accordance with the National Electrical

Code to eliminate shock hazard.

WARNING: Use 90˚copper conductors only.

1. Select proper wire gauge and type for supply conductors in accor-

dance with the National Electrical Code and local wiring codes fol-

lowing wiring diagram supplied (See recommendations for dis-

connect switches and fusing).

2. The unit is completely wired and pre-tested before shipment. No

internal wiring is required. Check all electrical connections for

tightness and retighten if necessary before energizing.

If a separate control circuit is used, the control circuit should be

connected to the control terminal block, inside access door (not

required with transformer).

3. Safety Switches — WARNING: Purchaser should use a

safety switch employing circuit breakers or fuses

between his main power source and the boiler.

4. Because of their water lines, boilers are susceptible to lightning

damage. Industrial type lightning protectors should be installed per

manufacturer’s recommendations at your service entrance. Check

your contractor or electrical dealer for recommended type for your

system.

5. Be sure all electrical connections are sufficiently tightened.

6. WARNING: Substitution of components or modifica-

tion of wiring system voids the warranty and may

lead to dangerous operating conditions.

7. SPECIAL INSTRUCTIONS FOR CUSTOMERS SUPPLY-

ING THEIR OWN CONDENSATE OR PUMP SYSTEMS.

A. Check the voltage of the motor before making the wiring con-

nection. Some Chromalox boilers are supplied with dual volt-

age systems. The motor should always match the voltage of the

control circuit.

B. The motor circuit should be wired into the pump control as

shown in wiring diagram (float type pump control). If boiler is

equipped with solid state pump control, refer to wiring diagram

and use terminals 5 and 2.

Use Applicable wiring diagrams based on model number and power voltage.

CHPES-6A

1

1

1

CHPES-30A

2

2

3

CHPES-100A

8

8

9

CHPES-9A

1

1

1

CHPES-36A

2

2

3

CHPES-135A

10

11

CHPES-12A

1

1

1

CHPES-48A

4

4

5

CHPES-160A

12

12

CHPES-18A

1

1

1

CHPES-60A

6

6

7

CHPES-180A

10

10

CHPES-24A

2

2

3

CHPES-72A

6

6

7

Export

14

2PS

BR

Heater

Contactors

Feed Water

Boiler On

3

GND

B

FU9

B 1PB

Off

1

GND

1

GND

1 HTR

C1

FU1

FU2

FU3

FU8

FU7

H1

H2

X1

X3

L3

1L1

1L3

1L2

L2

L1

X2

X4

Optional Transformer

1

1

C1

2

2

C4

C3

C2

R

1LT

Y

On

IFS

O

1PS

O

O

W

Feed Water

Electrical

Connection

2

1

1TB

1 2 3

3

GND

1

GND

2

GND

1

HTR

FU9

FU

1PB

Cabinet Exterior Left Side

Cabinet Exterior Right Side

Panel Layout

CR

FU4

FU5

FU6

2L1

2L3

2L2

1

Mtr

Customer

Connect

Feed Water

Motor

10L

30L

20L

IT1

IT3

IT2

CR

Wire Color Code

B

= Black

BR = Brown

R

= Red

O

= Orange

Y

= Yellow

G

= Green

BL = Blue

W = White

* Boilers under 40 Amps total (not fused)

4