Maintenance renewal parts identification – Chromalox CHPES-6A User Manual

Page 18

18

MAINTENANCE

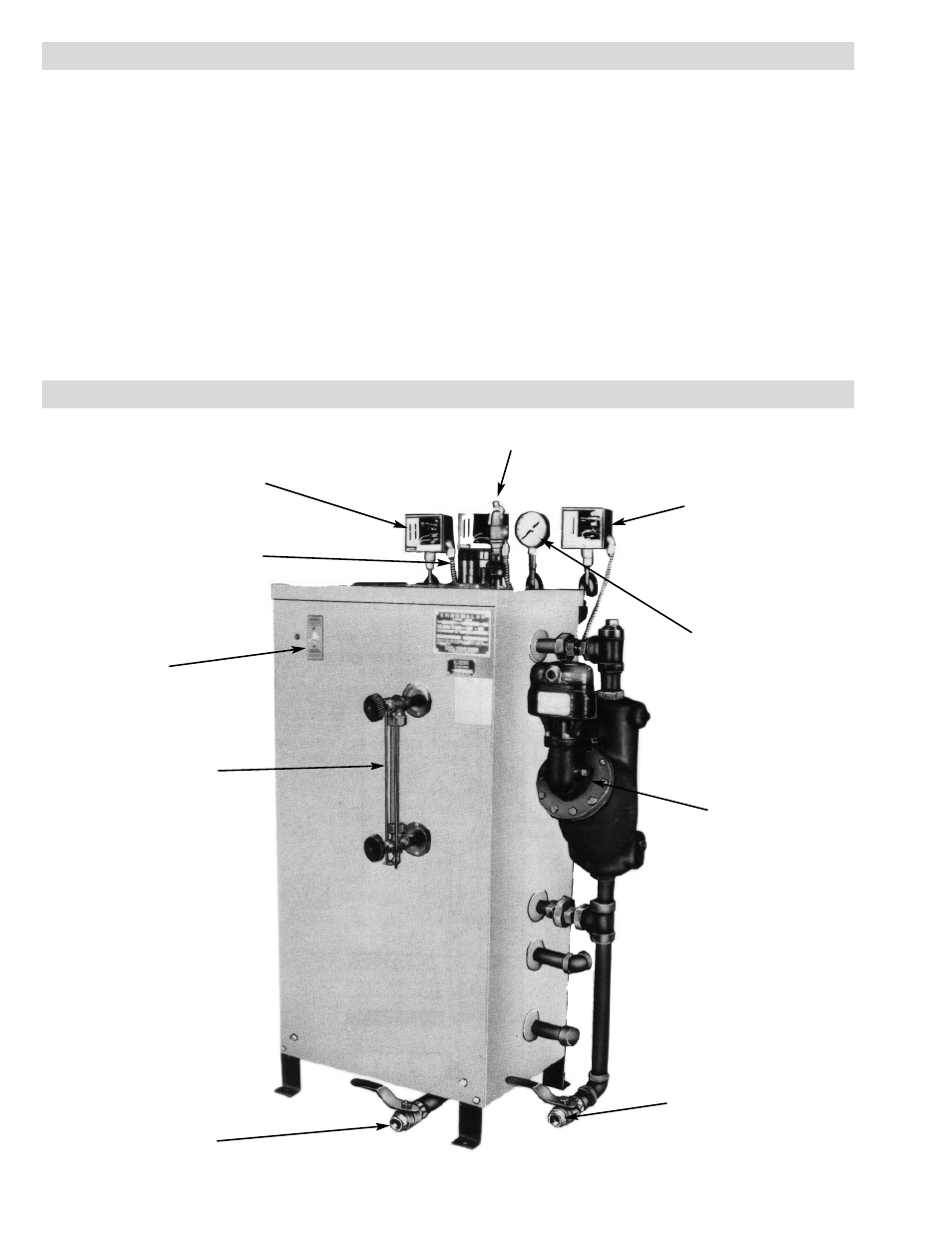

RENEWAL PARTS IDENTIFICATION

Drain Blowdown Valve

Drain Blowdown Valve

Water Level Sight Glass

On/Off Switch and

Pilot Light

Steam Outlet

Operating Pressure Control

Range 10-300 Psi

Safety Valve

Manual Reset High

Limit Control

Pressure Gauge, 0-600 Psi

McDonnell & Miller #194

Low Water Cutoff/Pump

Check Valve/Water Inlet

(not shown)

READ COMPLETELY BEFORE STARTING WORK

1. Disconnect boiler from electric power supply at main safety

switch or fuse panel. Then, turn boiler switch to “off” position.

2. On automatic feed units, close valve on incoming water line. Drain

boiler completely of water.

3. Open boiler door to expose heating element.

4. Disconnect wire (electric) leads connecting element to main power

system of boiler. Again note wire connections to facilitate

reassembly. Proceed to remove (6) 5/16-18 bolts from flange.

5. Thoroughly clean boiler flange of all foreign material. Be certain

no part of old gasket remains on boiler flange.

6. Apply “Slic-Tite” Gasket Compound or equal to both surfaces of

new gasket with supplied replacement element. Proceed to install

element flange assembly with gasket between boiler flange and

element flange. In doing this, be careful to align flange holes so

wire connection terminals on element assembly are in line with

previously disconnected wire leads to facilitate easy connections.

7. When all (6) flange bolts are tight, connect all wires to terminals.

Make certain wires are clean and bright to assure good electrical

contact and nuts on screws are firmly secured.

WARNING: Avoid use of chemical cleaning com-

pounds. Follow maintenance instructions.

8. Open water valve so water supply can reach boiler feed mecha-

nism.

9. Put main safety switch to “on” position.

10. Turn boiler to “on” position.

11. As boiler automatically refills, observe the new flange assemble

for possible leaks. If water is noticed, to bolts must be retightened.

Before doing this, turn the boiler off at the main fuse safety switch.

12. As boiler is heated to working pressure, check flange assembly

again for leaks.

WARNING: Avoid the use of chemical cleaning com-

pounds. Follow maintenance instructions