Carrier 38BRC User Manual

Page 3

wet cloth, braze sweat connections using industry accepted meth-

ods and materials. Consult local code requirements. Refrigerant

tubing and indoor coil are now ready for leak testing. This check

should include all field and factory joints.

Step 7—Make Electrical Connections

To avoid personal injury or death, do not supply power to unit

with compressor terminal box cover removed.

Be sure field wiring complies with local and national fire, safety,

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit

protection device.

NOTE:

Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage or phase imbalance (3 phase)

may fluctuate above or below permissible limits.

NOTE:

Use copper wire only between disconnect switch and

unit.

NOTE:

Install branch circuit disconnect of adequate size per

NEC to handle unit starting current. Locate disconnect within sight

from and readily accessible from unit, per Section 440-14 of NEC.

ROUTE GROUND AND POWER WIRES

Remove access panel to gain access to unit wiring. Extend wires

from disconnect through power wiring hole provided and into unit

control box.

According to NEC, ANSI/NFPA 70, and local codes, cabinet

must have an uninterrupted or unbroken ground to minimize

personal injury if an electrical fault should occur. The ground

may consist of electrical wire or metal conduit when installed

in accordance with existing electrical codes. Failure to follow

this warning can result in an electric shock, fire, or death.

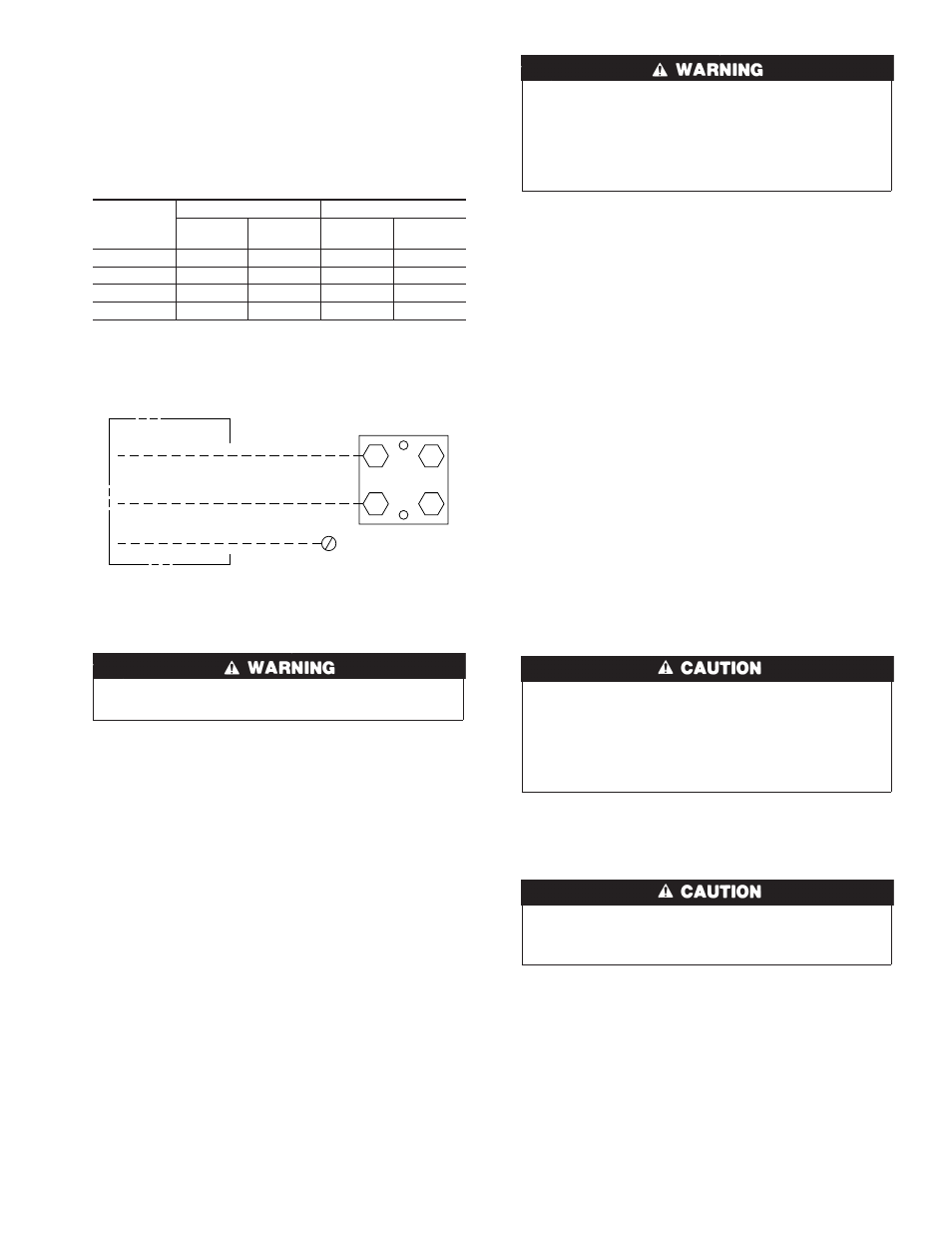

CONNECT GROUND AND POWER WIRES

Connect ground wire to ground connection in control box for

safety. Connect power wiring to contactor as shown in Fig. 3.

CONNECT CONTROL WIRING

Route 24v control wires through control wiring grommet and

connect leads to control wiring. (See Fig. 5.) Use No. 18 AWG

color-coded, insulated (35°C minimum) wire. If thermostat is

located more than 100 ft from unit, as measured along the control

voltage wires, use No. 16 AWG color-coded wire to avoid

excessive voltage drop.

Use furnace transformer, fan coil transformer, or accessory trans-

former for control power, 24v/40va minimum.

NOTE:

Use of available 24v accessories may exceed the mini-

mum 40va power requirement. Determine total transformer load-

ing and increase the transformer capacity or split the load with an

accessory transformer as required.

Step 8—Compressor Crankcase Heater

A crankcase heater is required if refrigerant tubing is longer than

50 ft.

Step 9—Install Electrical Accessories

Refer to the individual instructions packaged with kits or acces-

sories when installing.

Step 10—Start-Up

• 3-phase scroll compressors are rotation sensitive.

• A flashing LED on phase monitor indicates reverse rotation.

(See Fig. 4 and Table 2.)

• This will not allow contactor to be energized.

• Disconnect power to unit and interchange 2 field wiring

leads on unit contactor.

1. When equipped with a crankcase heater, energize heater a

minimum of 24 hr before starting unit. To energize heater

only, set thermostat to OFF mode and close electrical discon-

nect to outdoor unit.

Service valve gage ports are equipped with Schrader valves.

To prevent personal injury, wear safety glasses and gloves

when handling refrigerant.

2. Fully back seat (open) liquid and vapor service valves.

3. Unit is shipped with valve stem(s) front seated (closed), and

caps installed. Replace stem caps after system is opened to

refrigerant flow. Replace caps finger-tight and tighten addi-

tional 1/6 turn with wrench.

4. Close electrical disconnects to energize system.

5. Set room thermostat at desired temperature. Be sure set point

is below indoor ambient temperature.

6. Set room thermostat at COOL and fan ON or AUTO modes,

as desired. Operate unit for 15 minutes. Check system

refrigerant charge. See Check Charge section.

Table 1—Refrigerant Connections

and Recommended

Liquid and Vapor Tube Diameters (In.)

UNIT SIZE

LIQUID

VAPOR

Connect

Diameter

Tube

Diameter

Connect

Diameter

Tube

Diameter

018, 024

3/8

3/8

3/8

5/8

030, 036

3/8

3/8

3/8

3/4

042-048

3/8

3/8

7/8

7/8

060

3/8

3/8

7/8

1-1/8

Note: Tube diameters are for lengths up to 50 ft. For tubing lengths greater

than 50 ft, consult your local distributor or Long-Line Application Guideline.

Fig. 3—Line Power Connections

A88174

CONTACTOR

DISCONNECT

PER N.E.C. AND/OR

LOCAL CODES

FIELD POWER

WIRING

FIELD GROUND

WIRING

GROUND

LUG

3