Recommended tools, equipment and materials – Taylor-Wharton VJ Series Tanks User Manual

Page 21

21

5.

Leaking safety valve.

a.

Dirt or ice under valve or disc.

b.

Improper valve set point.

c.

Damaged valve seat or disc.

a.

Thaw out valve. Replace if necessary.

b.

Replace valve.

c.

Replace valve.

6.

Tank vacuum leak.

a.

Leak in Vacuum Jacket Relief Device.

b.

Evacuation Valve leak.

c.

Vacuum Probe or Vacuum Valve

d.

Tank Vacuum Jacket leak.

a.

Refer to Analyzing Vacuum

b.

Replace Evacuation Valve diaphragm.

c.

Replace faulty component. Re-

d.

Refer to Analyzing Vacuum

7. Inability to obtain desired vacuum

when re-evacuating.

a.

Defective vacuum pump.

b.

Incorrect vacuum reading.

c.

Defective Vacuum Gauge Tube.

d.

Leak in connections between vacuum

e.

Excessive moisture in insulation.

f.

Moisture in pump lubricant.

a.

Repair or replace vacuum pump.

b.

Repeat vacuum measurement.

c.

Replace Vacuum Gauge Tube.

d.

Repair Leaks

e.

Evacuate insulation space with cold

d.

Replace lubricant.

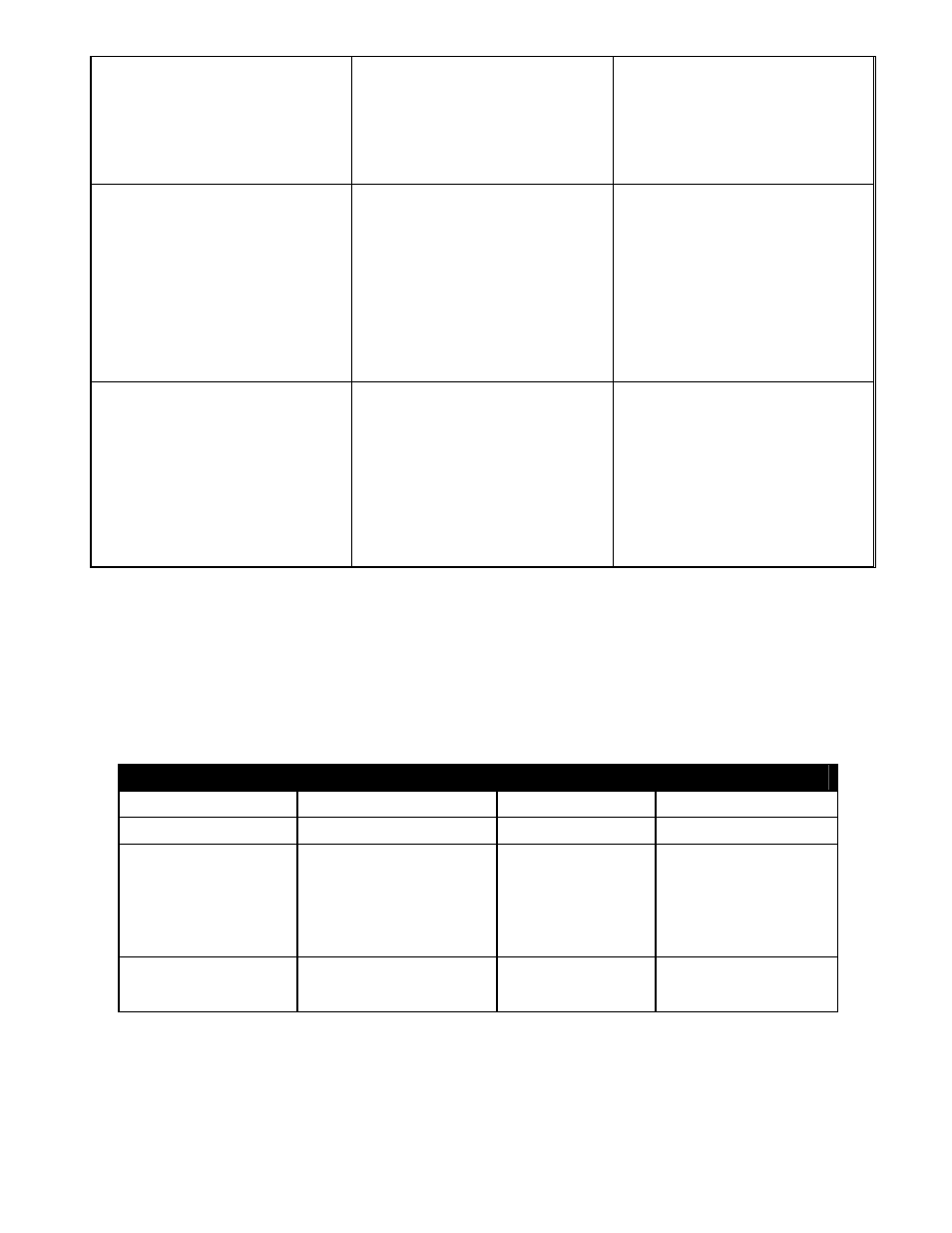

RECOMMENDED TOOLS, EQUIPMENT AND MATERIALS

Components in the "Reference" column are provided to indicate where various tools, equipment,

and material are used. For locations of various suppliers listed, refer to the Address List section.

REFERENCE

DESCRIPTION

PART NUMBER

SOURCE

All Piping

Snoop Liquid Leak Detector

-

Nupro Company

Liquid Level Gauge

Pointer Puller

-

ITT Barton

Vacuum Gauge Tube

Krylon Crystal Clear Coating

Vacuum Gauge

Liquid High Vacuum Sealant 4oz.

Epoxy

1301

TV-4A, VT-6

4036

A-12

Borden

Teledyne Hastings-Raydist

Airserco Mfg. Co.

Armstrong Prod.

Vacuum Jacket Relief Device

Celevacene Grease

Chlorothene VG

-

-

Consolidated Vacuum Corp.

Dow Chemical Co.