Moving the tank, Trouble-remedy guild – Taylor-Wharton VJ Series Tanks User Manual

Page 20

20

MOVING THE TANK

Purge and warm tank prior to removal and shipping. The tank must not be shipped cold because

the internal supports are not designed to withstand the shipping loads when the tank is cold.

Before moving the tank, refer to Taylor-Wharton Cryogenics Customer Service Dept. Refer to

rigging information in "Installation" section when relocating the tank.

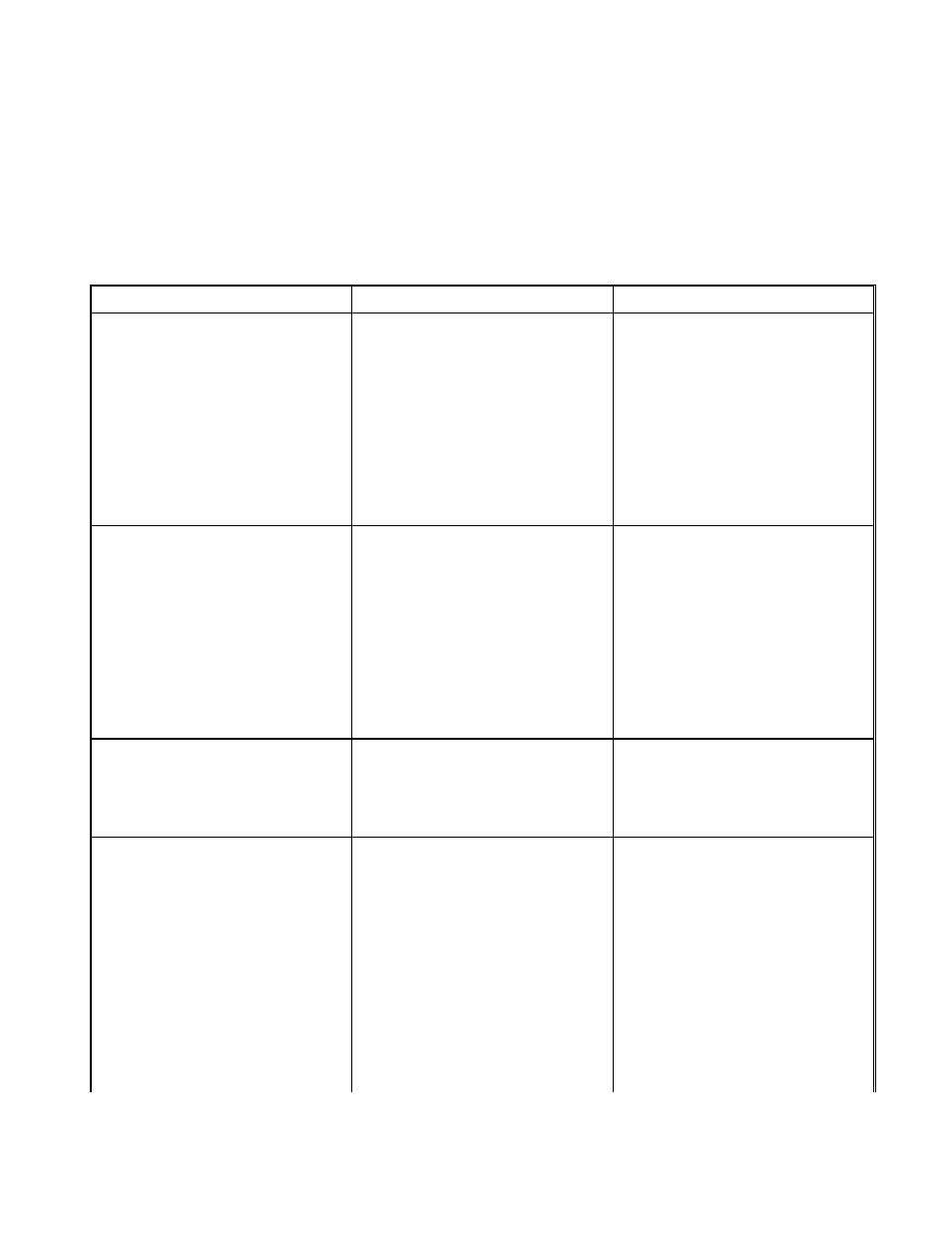

TROUBLE-REMEDY GUILD

TROUBLE

POSSIBLE CAUSES

REMEDY

1.

Tank Pressure too low.

a.

Pressure Vessel Safety Valve leaking

b.

Piping leaks to atmosphere.

c.

Low liquid level.

d.

Excessive product withdrawal.

e.

Improper filling procedure

a.

Thaw out valve or replace if

b.

Test and repair tank

c.

Refill tank.

d.

Install higher capacity Pressure

e.

Refer to filling instruction in

2.

Excessive tank pressure.

a.

Extensive shutdown time.

b.

Low withdrawal rate.

c.

Malfunction of Pressure Building

d.

Malfunction of tank Pressure Gauge.

e.

Lack of refrigeration caused by low

f.

Malfunction of Back Pressure Valve.

a.

No Remedy.

b.

No Remedy.

c.

Refer to Step 3, this section.

d.

Replace Pressure Gauge.

e.

Refill tank.

f.

Refer to Step 3, this section.

3.

Malfunction of Back Pressure Valve.

a.

Improper valve set point.

b.

Dirt on valve seat or valve

a.

Check valve set point reset if required;

b.

Disassemble, inspect, clean, and

4.

Erratic or erroneous Liquid Level

Gauge readings.

a.

Leaking gauge lines.

b.

By-pass valve open.

c.

Contents Gauge needle stuck.

d.

Contents Gauge needle not zero

e.

Gauge line reversed.

f.

Contents Gauge damaged or faulty.

g.

Plugged gauge lines.

a.

Test and repair leaks.

b.

Close by-pass valve.

c.

Tap Contents Gauge slightly. Inspect

d.

Adjust as required.

e.

Connect properly.

f.

Replace Contents Gauge.

g.

Disconnect lines at Contents Gauge