Taylor-Wharton LS Series User Manual

Page 6

Changing Liquid Level

The liquid level in the unit is determined by the position of

the sensor probes in the sensor tube next to the fill tube.

These probes have been set at installation to maintain a

specific liquid level. The controller operates a fill cycle that

adds liquid at low level, fills to a predetermined high level,

then stops the fill. The cycle repeats when liquid drops to

the low level over time.

Sensor probe positions may be changed to define new high

and low liquid levels, and these levels may be set indepen-

dently to vary the liquid level differential between fills. If a

higher liquid level is desired, withdraw the sensor tube; for a

low level, the sensors must be moved further into (down)

the sensor tube.

CAUTION: Ice or frost in the sensor

tube may restrict movement of

sensor probes in the tube. Do not

pull excessively on sensor wiring

while attempting to change sensor

position. It may be necessary to

remove the sensor from the con-

tainer and allow it to thaw before the

sensor can be repositioned.

Increasing the distance between low and high sensor

probes allows greater liquid level fluctuation, less frequent

filling and reduced fill loses; decreasing the distance has

the opposite effect.

To set the liquid level to a different point, or to change the

level differential, the sensors must be repositioned. Their

position within the sensor tube is held in place by the

sensor tube plug, which is split to allow the sensor leads to

pass through. The sensor tube plug holds the sensors at

the position necessary to maintain a specific liquid levels.

Two different sensor heights are specified by their position

within the sensor tube. The low and high sensor pods are

separately positioned to set the liquid levels at which the

controller will start or terminate each fill cycle. Insert the

sensor leads into the perforated sensor tube to the desired

height. Mark the sensor leads at the top of the sensor tube.

Pull the leads out just enough to install the sensor tube plug

around the marks on the sensor leads. Insert sensor plug

securely into the mouth of the tube. Perform this operation

carefully, so the sensor leads are not damaged.

NOTE:

The high level sensors must be at least

1.75 in. (5.1 cm) above the low level

sensor pod.

After repositioning sensors, check to be sure the sensor

tube is secured to the fill tube and the sensor wires are

dressed and clear of rack operation, and turn the controller

on. The controller should fill the refrigerator to the new

liquid level. After sensors are repositioned, the controller

should maintain the liquid pool at the new operating level.

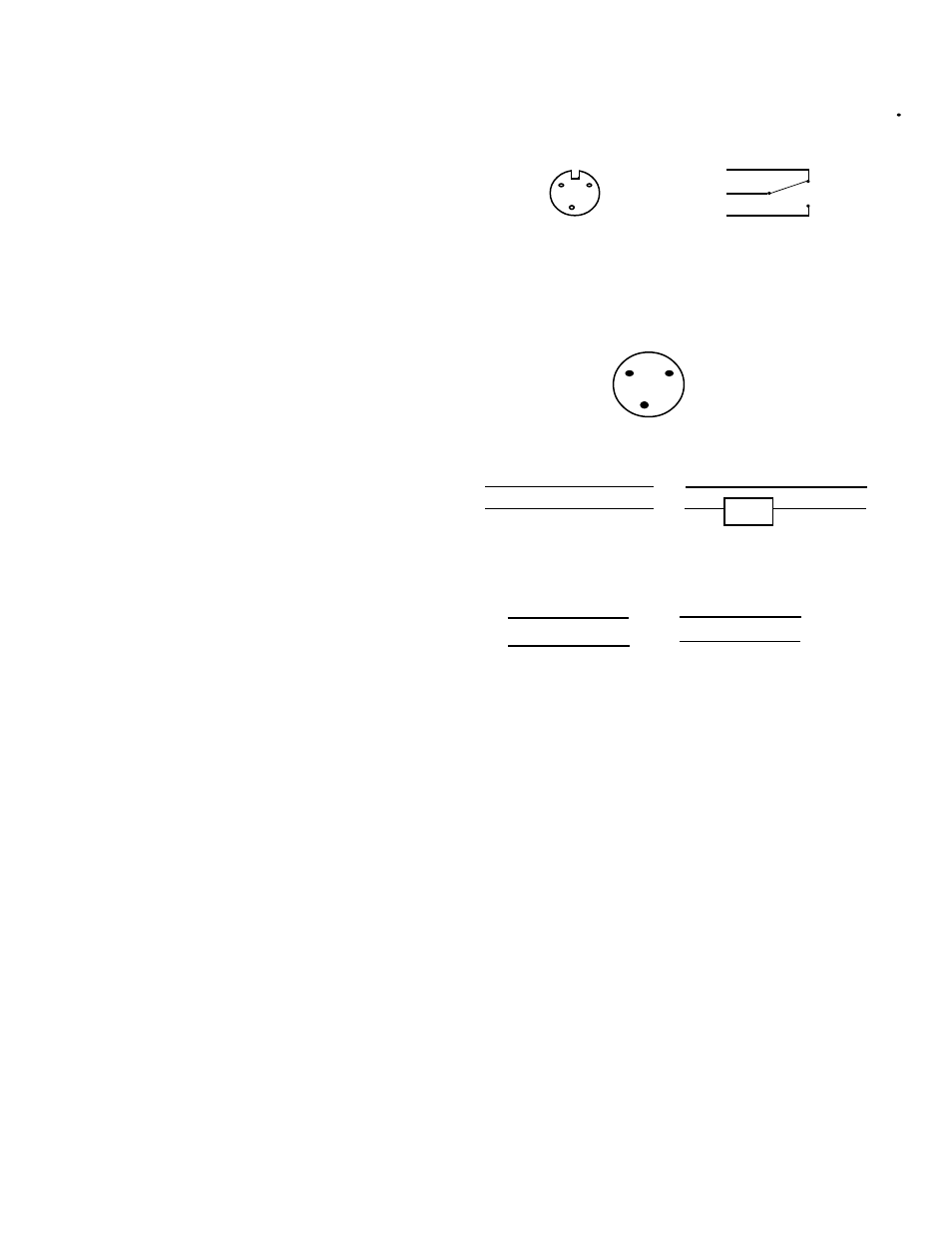

Remote Alarm Connection

Relay connections are provided on an external for user

installation of a remote alarm circuit (see Figure 8.) Wiring

external power supply and alarm devices must be supplied

by the user. During an alarm condition, contacts 1 & 2 are

closed and contacts 2 & 3 are open.

Remote Alarm Connection on Taylor-Wharton Freezers

Back panelson most Taylor-Wharton freezers are equipped

with a 3 point electrical socket. The socket connects to a

control board mounted, SPDT (single pole double throw)

relay, rated at 10 amps, 125 VAC.

A Switchcraft plug (#05GM3M) connects to the above

socket. It is available with leads as Taylor-Wharton part

#R06K-8C20. Approximately 9 of wire extend from the

plug. The gray wire connects to Pin #1, orange wire to Pin

#2 and the purple wire to Pin #3.

To connect an AC load, such as an alarm light or buzzer,

connect as shown below:

For automatic dialers and other alarm systems that are

alarmed on either a contact make or break, connect as

shown below:

MAINTENANCE

LS Series CryoStorage Maintenance

Defrosting your K Series CryoStorage System

All liquid nitrogen storage systems are subject to ice and

frost buildup over time. Regular preventive maintenance

programs should be instituted to remove ice and frost from

the sensor and fill tubes and from the refrigerator lid.

Ice and frost build up in the sensor tube may result in false

readings being relayed to the controller from the sensors.

Ice can form a thermal barrier around a level sensor,

rendering it insensitive to the temperature differences

between vapor and liquid. Sensors and thermocouple

should be removed regularly and inspected for ice and frost

build up.

NOTE:

Ice or frost in the sensor tube may restrict

the movement of sensor probes in the

tube. Do not pull excessively on the sensor

wiring while attempting to change sensor

position. It may be necessary to remove

the fill tube and tube from the container

and allow it to thaw before the sensors can

be repositioned.

~

~

AC Line

AC Line

orange

gray

Alarm

orange

purple

2

3

1

2

orange

gray

Alarm on break

Alarm on make

1

2

3

1

2

3

1

3 (NO)

(NC)

3

2

1