Taylor-Wharton LS Series User Manual

Page 4

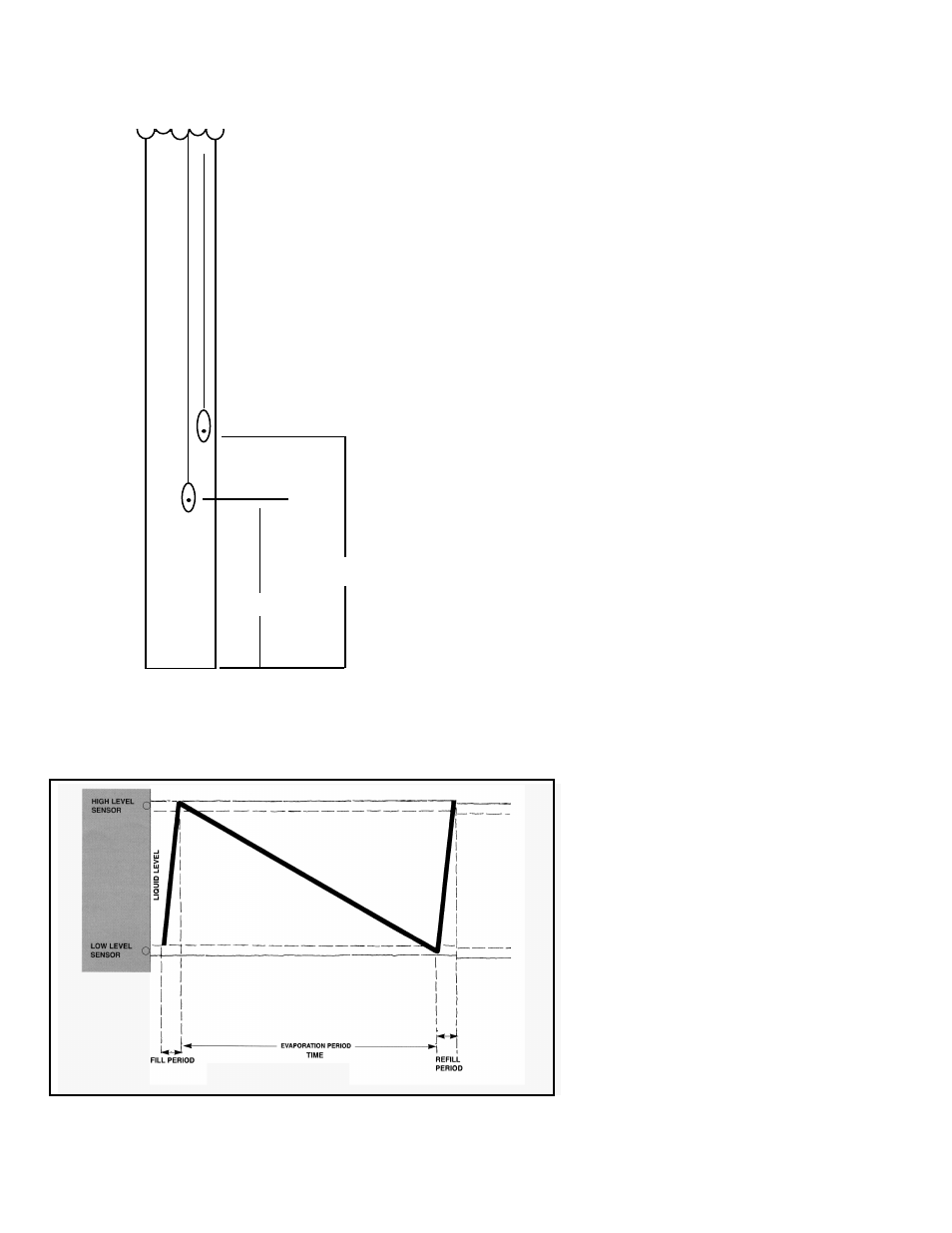

Figure 2. Sensor Positioning for the AutoTend

.25 inches

Figure 4. Normal Fill/Evaporation Cycle Chart

CONTROLLER OPERATION

Introduction

The AUTO-TEND Control System is designed to provide

simple, reliable liquid level control in your LN

2

freezer. It

operates on 24 Volts AC and uses a two-sensor system to

open and close a solenoid valve. The liquid level, the sensor

condition, the valve condition, and the LN

2

supply condition

are indicated by lights on the front panel.

Installation:

The AUTO-TEND Control System is designed to mount

onto your Taylor-Wharton Cryogenic refrigerator. The

components plug into the back of the control panel as

follows: The Solenoid Valve has a 2-pin connector. The

sensor assembly has a 4-pin connector. These plug into the

mates on the back of the control panel.

The sensor assembly should be installed with the yellow

and orange wires at the High Level and the black and red

wires at the Low Level. These are labeled for easy refer-

ence.

The Auto-Tend controller should not require additional

attention to maintain liquid level if an adequate supply of

liquid nitrogen is maintained. If your protocol calls for you to

top off the cryostorage system at the end of a work day or

work week, press the Start button. The unit will fill to the

upper allowable liquid level and stop automatically. You may

choose to manually stop the fill by pressing the STOP

button at anytime during the fill.

Normal Fill Cycle

When the unit is filled and the controller is operating, the low

level sensor is immersed in liquid nitrogen (see Figure 4.)

Its resistance value is interpreted by the controller as in

liquid. At the same time, the high level sensor is above the

liquid pool sending the controller an in-gas signal. In this

condition, the control panel will read Normal. As liquid

nitrogen evaporates, the liquid level in the refrigerator drops

slowly until the low level sensor is above the liquid and

sends a different signal to the controller. The controller

interprets this condition as low liquid and opens

the fill solenoid valve admitting more refrigerant.

The unit fills slowly, the control panel will read

LOW when the liquid level is above the low

level sensor. It will continue to display the green

filling light until the high level sensor is immersed

in liquid. Once the level of the liquid reaches the

point of the high level sensor, the Solenoid Valve

will close. Figure 4 illustrates this cycle in graph

form where liquid level is plotted against time,

and display graphics are shown as they appear

at key points in the cycle.

Start Fill

2.0 inches

Stop Fill