Carrier 38YSA User Manual

Page 6

SEQUENCE OF OPERATION — With power supplied to indoor

and outdoor units, transformer is energized.

Cooling

On a call for cooling, the thermostat makes circuits R-O, R-Y, and

R-G. Circuit R-O energizes the reversing valve, switching it to

cooling position. Circuit R-Y energizes contactor, starting outdoor

fan motor and compressor circuit. R-G energizes indoor unit

blower relay, starting indoor blower motor on high speed.

When thermostat is satisfied, its contacts open, de-energizing

contactor and blower relay. Compressor and motors should stop.

Heating

On a call for heating, the thermostat makes circuits R-Y and R-G.

Circuit R-Y energizes contactor, starting outdoor fan motor and

compressor. Circuit R-G energizes indoor blower relay, starting

blower motor on high speed.

Should the temperature continue to fall, R-W2 is made through

second-stage room thermostat bulb. Circuit R-W2 energizes a

sequencer, bringing on first bank of supplemental electric heat and

providing electrical potential to second heater sequencer (if used).

If outdoor temperature falls below the setting of outdoor thermo-

stat, (field-installed option) contacts close to complete circuit and

bring on second bank of supplemental electric heat.

When thermostat is satisfied, its contacts open, de-energizing

contactor and sequencer. All heaters and motors should stop.

Defrost

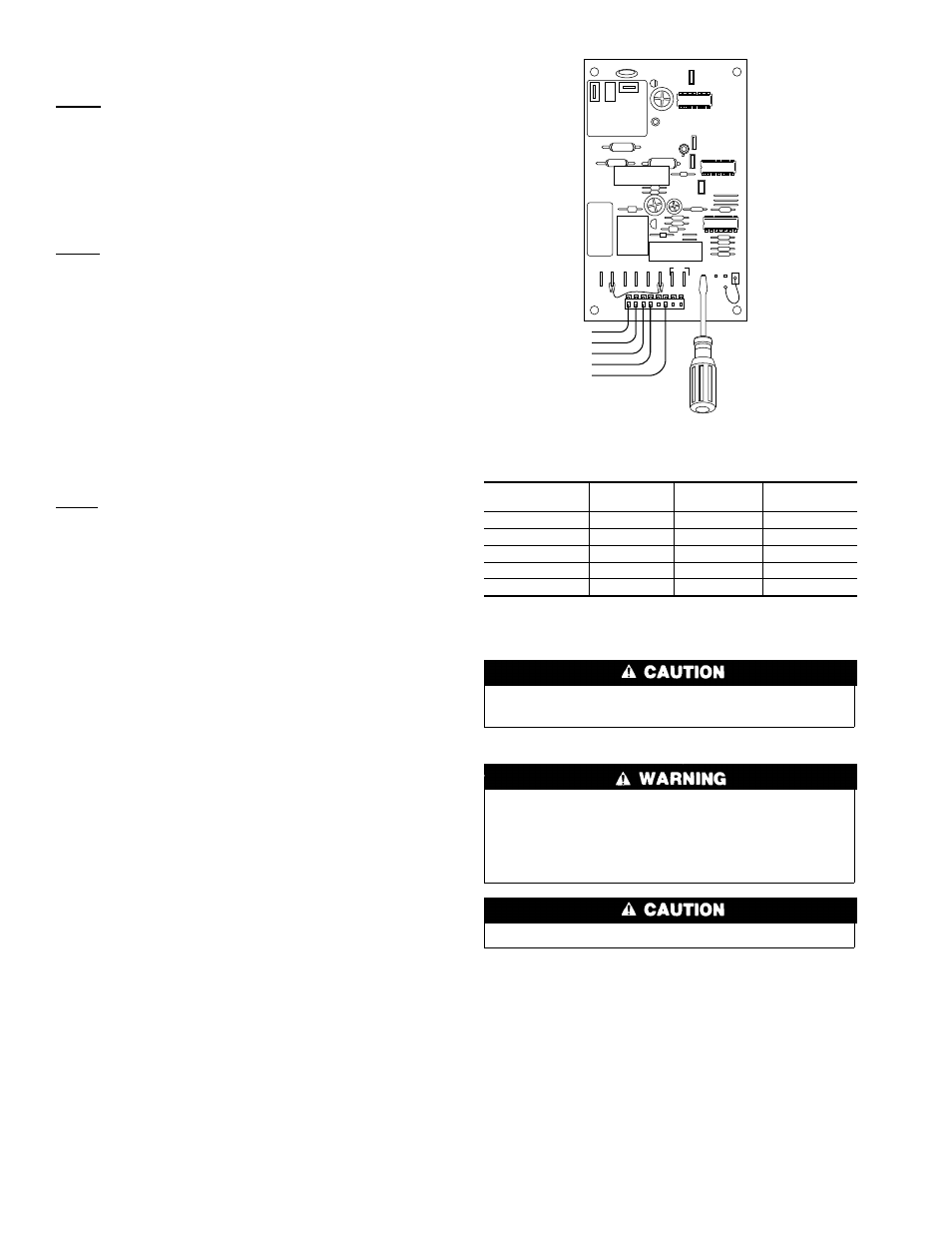

The defrost control is a time/temperature control which includes a

field-selectable (quick connects located at board edge) time period

between defrost cycles (30, 50, and 90 minutes), factory set at 90

minutes.

The electronic timer and defrost cycle will start only when

contactor is energized and defrost thermostat is closed.

The defrost mode is identical to cooling mode except that the

outdoor fan motor stops and second-stage heat is turned on to

continue warming conditioned space.

To initiate defrost, the defrost thermostat must be closed. This can

be accomplished as follows:

1. Turn off power to outdoor unit.

2. Disconnect outdoor fan motor lead from OF2 on control

board. Tape lead to prevent grounding.

3. Restart unit in heating mode, allowing frost to accumulate on

outdoor coil.

4. After a few minutes in heating mode, liquid-line temperature

should drop below the closing point of defrost thermostat,

approximately 30˚F.

5. Short between speed-up terminals with a flat bladed screw-

driver. (See Fig. 11.) This reduces the timing sequence to

1/256 of the original time.

6. When you hear reversing valve change position, remove

screwdriver immediately. Otherwise the control will terminate

normal 10-minute defrost cycle in approximately 2 sec.

NOTE:

Length of defrost cycle will be dependent upon the length

of time it takes to remove screwdriver from test pins after

reversing valve has shifted.

7. Unit will remain in defrost for remainder of defrost cycle time

or until defrost thermostat reopens.

Step 10—Checking Charge

Do not vent refrigerant to atmosphere. Recover during system

repair or final unit disposal.

Factory charge is shown on unit rating plate. (See Fig. 2.)

Service valve gage ports are not equipped with Schrader

valves. To prevent personal injury, make sure gage manifold

is connected to the valve gage ports before moving valves off

fully back seated position. Wear safety glasses and gloves

when handling refrigerant.

Compressor damage may occur if system is overcharged.

Check charge in cooling and heating mode by following procedure

shown on subcooling charging tables located on unit information

plate.

CARE AND MAINTENANCE

For continuing high performance, and to minimize possible

equipment failure, it is essential that periodic maintenance be

performed on this equipment. Consult User’s Manual for proper

frequency of maintenance. Frequency of maintenance may vary

depending upon geographic areas, such as coastal applications.

Step 1—Leave User’s Manual with Homeowner

Explain system operation and maintenance procedures outlined in

User’s Manual.

Fig. 11—Defrost Control

Defrost Control Speed-Up Timing Sequence

for CES0110063/CES0130024

PARAMETER

MINIMUM

MAXIMUM

SPEED-UP

(NOMINAL)

30-min cycle

27

33

7 sec

50-min cycle

45

55

12 sec

90-min cycle

81

99

21 sec

10-min cycle

9

11

2 sec

5-min cycle

4.5

5.5

1 sec

A91444

OF1

OF2

O

R

T2

Y

TI DFT

C

TEST 30 50 90

W1

O

R

W2

Y

C

CES0110063,

CES0130024

6