Carrier 52C User Manual

Page 7

7

■

INSTALL CHASSIS IN SLEEVE (See Figures 11 to

13)

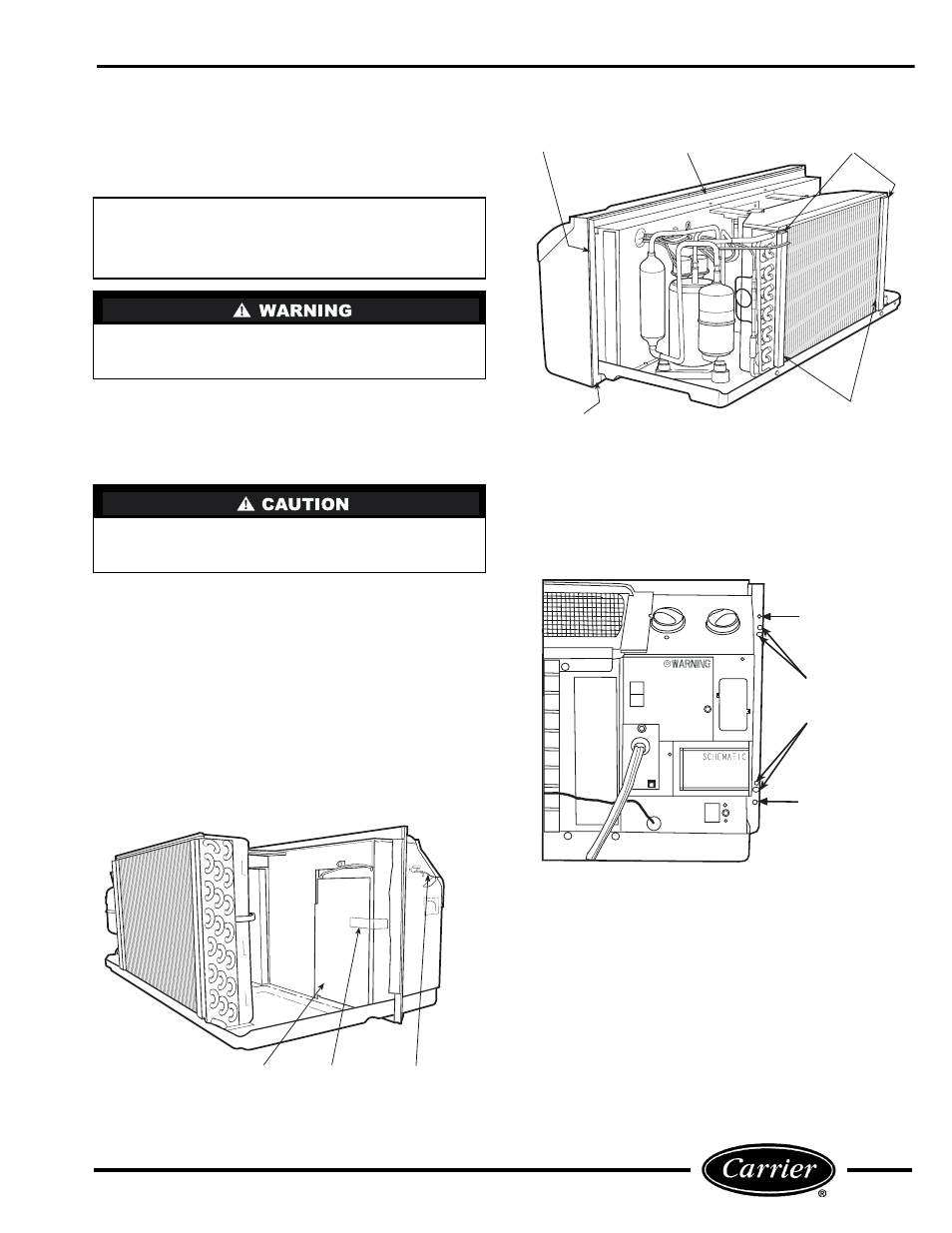

1. Inspect foam gaskets (top, bottom, both sides) on

chassis. Replace foam gaskets if torn or missing.

2. If retrofitting into a GE, Amana, Trane, or

Friedrich wall sleeve/grille, remove any existing

foam seals from competitive manufacturer’s grille

before installing unit.

3. Remove shipping tape from vent door. See Figure 11.

4. Carefully remove power cord packing material

and discard.

5. Lift chassis level with wall sleeve.

6. Slide chassis into wall sleeve until foam gaskets

rest firmly against front of wall sleeve. See

Figure 12.

7. Screw chassis to wall sleeve with four 1

3

/

4

-in. long

screws taped to the control box. Screw holes are

located on both sides of the mounting angles of the

chassis. For Carrier wall sleeves, use the top-most

and bottom-most screw holes. For competitive

wall sleeves, line up the correct attachment holes

on the chassis with the holes in the sleeves. See

Figure 13.

IMPORTANT: The gaskets combine with the sleeve

face to create a weather barrier. If the chassis is

installed in a non-Carrier sleeve, this weather bar-

rier may not be effective.

Chassis weighs up to 150 lb. For personal protection,

seek help when lifting the unit. Lift unit by holding

unit basepan.

Failure to remove shipping tape will prevent fresh

air vent door from opening and may result in damage

to the vent door cable.

BOTTOM SCREW

HOLE

(CARRIER SLEEVE)

TOP SCREW HOLE

(CARRIER SLEEVE)

COMPETITIVE

MANUFACTURER

SLEEVE

ATTACHMENT

HOLES

TOP

GASKET

SIDE

GASKET

BOTTOM

GASKET

COIL TUBE

SHEETS

FACTORY-INSTALLED

FOAM SEALS

FIGURE 12 — UNIT GASKETS

AND TUBE SHEETS

FIGURE 13 — CHASSIS MOUNTING

VENT

DOOR

SHIPPING

TAPE

VENT DOOR

CABLE

FIGURE 11 — LOCATION OF SHIPPING TAPE

ON VENT DOOR