Cooper Bussmann CT02MAN User Manual

Page 48

46

Cooper B-Line, Inc

Cable Tray Manual

TABLE III

TEMPERATURE RISE TESTS, CONDUIT CLAMPS

FOR BONDING RIGID CONDUIT TO CABLE TRAY

Test

Test

I

2

T

Rigid Conduit

Cable Tray

Temp.

Current

Time

mult.

Rise

Condition After Test

Amperes

Cycles

10

6

Size

Material

Class

Material

°C

36,000

16

344.7

4"

Aluminum

II

Aluminum

19

No arcing or damage

20,900

60.5

441.2

4"

Aluminum

II

Aluminum

70

No arcing or damage

12,100

178

433.3

4"

Aluminum

II

Aluminum

74

No arcing or damage

21,000

20

146.8

4"

Steel

II

Steel

(?)

Zinc melted at point where

conduit contacted with tray

3,260

900

159.5

4"

Steel

II

Steel

63

No arcing or damage

21,000

30

220

2"

Aluminum

II

Aluminum

21

No arcing or damage

12,100

120.5

294.2

2"

Aluminum

II

Aluminum

59

No arcing or damage

8,000

245

261.1

2"

Aluminum

II

Aluminum

44

No arcing or damage

21,000

14

103.8

2"

Steel

II

Steel

62

Zinc melted at point where

conduit contacted with tray

12,000

60.5

145.4

2"

Steel

II

Steel

22

Slight arc between

clamp and tray

3,240

600

104.9

2"

Steel

II

Steel

49

No arcing or damage

21,000

20

146.8

1"

Aluminum

II

Aluminum

20

No arcing or damage

12,200

60.5

150.3

1"

Aluminum

II

Aluminum

24

No arcing or damage

12,100

14.5

35.3

1"

Steel

II

Steel

6

No arcing or damage

8,000

63.5

67.84

1"

Steel

II

Steel

59

No arcing or damage

1,980

44.5

2.9

1"

Steel

II

Steel

1

No arcing or damage

200A FU

Appendix Sheet 2

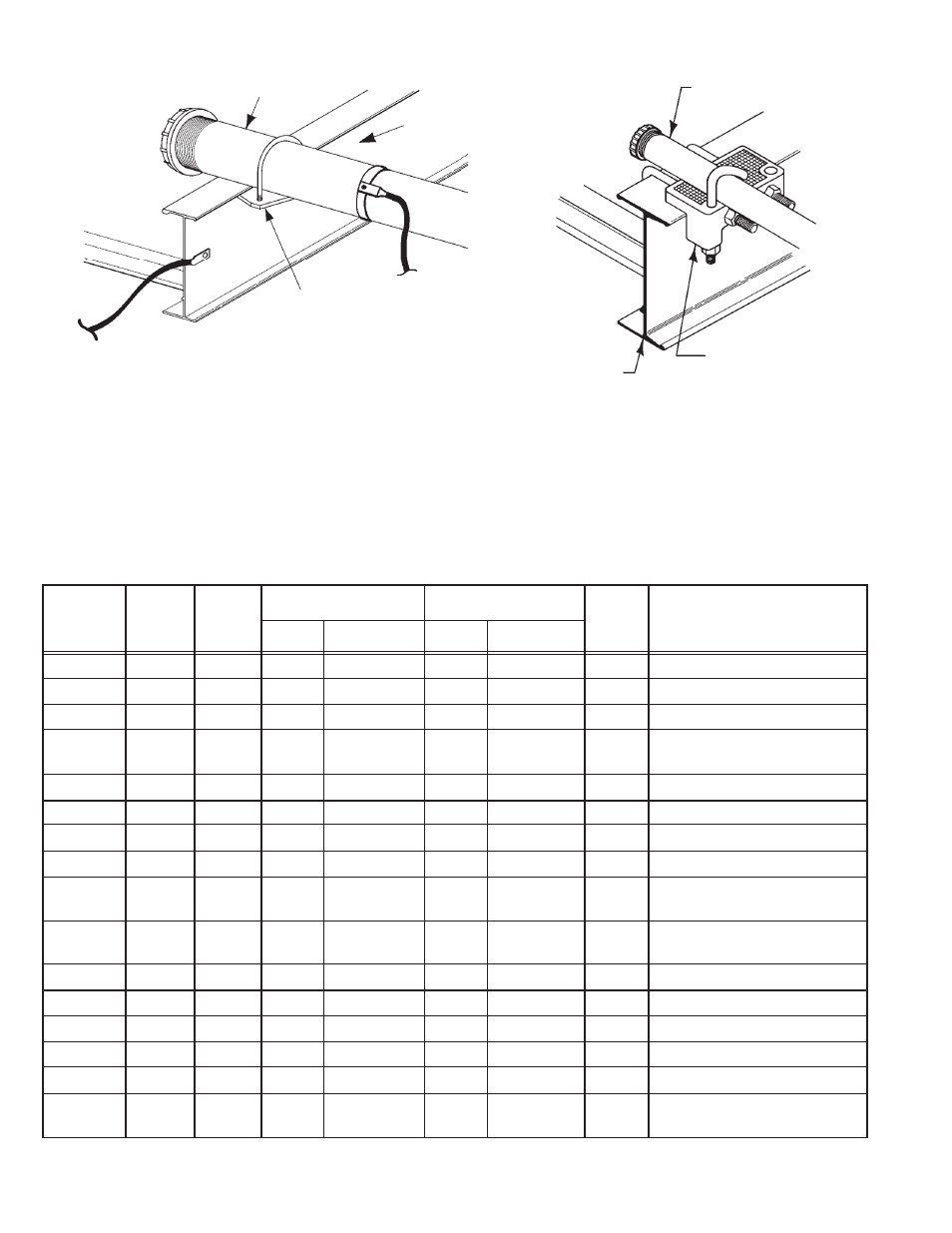

Conduit

UL Listed

Conduit Clamp

(9ZN-1158)

Cable Tray

Conduit

Cable Tray

Right Angle

Beam Clamp

To

Current

Source

To

Current

Source

Conduit Clamp Detail

Test Set-Up

CIRCUIT ARRANGEMENT FOR RIGID CONDUIT

TEMPERATURE RISE TESTS