Technically desirable installation – Cooper Bussmann CT02MAN User Manual

Page 39

392.11. Ampacity of Cables Rated 2000

Volts or Less in Cable Trays. (B) Single

Conductor Cables.

Single conductor cables can be installed in a cable

tray cabled together (triplexed, quadruplexed, etc.) if

desired. Where the cables are installed according to

the requirements of Section 392.10, the ampacity

requirements are shown in the following chart as

per Section 392.11(B)(1), (2), (3), & (4):

392.12. Number of Type MV and Type

MC Cables (2001 Volts or Over) in Cable

Trays.

Sum the diameters of all the cables (Sd) to

determine the minimum required cable tray width.

Triplexing or quadruplexing the cables does not

change the required cable tray width. Whether the

cables are grouped or ungrouped, all installations

must be in a single layer.

392.13. Ampacity of Type MV and Type

MC Cables (2001 Volts or Over) in Cable

Trays. (A) Multiconductor Cables (2001

Volts or Over).

Provision No. 1: Where cable trays are

continuously covered for more than six feet

(1.83 m) with solid unventilated covers, not

more than 95% of the allowable ampacities

of Tables 310.75 and 310.76 shall be

permitted for multiconductor cables.

Cables installed in cable trays with solid

unventilated covers must be derated. Where cable

tray covers are to be used, it is best to use raised or

ventilated covers so that the cables can operate in a

lower ambient temperature.

37

Cable Tray Manual

Cooper B-Line, Inc

Mult.

Solid

Applicable

Amp.

Sec.

Cable

Unventilated

Ampacity

Table

Special

No.

Sizes

Cable Tray

Tables

Values

Conditions

Cover

(*)

By

600 kcmil

No Cover

310.17

(1)

and

Allowed

and

0.75

Larger

(**)

310.19

600 kcmil

310.17

(1)

and

Yes

and

0.70

Larger

310.19

1/0 AWG

No Cover

310.17

(2)

through

Allowed

and

0.65

500 kcmil

(**)

310.19

1/0 AWG

310.17

(2)

through

Yes

and

0.60

500 kcmil

310.19

1/0 AWG

Maintained

(3)

& Larger

No Cover

310.17

1.00

Spacing Of

In Single

Allowed

and

One Cable

Layer

(**)

310.19

Diameter

Single

Conductors

310.20

Spacing Of

(4)

In Triangle

No Cover

[See NEC

2.15 x One

Config.

Allowed

Section

1.00

Conductor

1/0 AWG

(**)

310.15(B)]

O.D. Between

and Larger

Cables(***)

(*) The ambient ampacity correction factors must be used.

(**) At a specific position, where it is determined that the tray

cables require mechanical protection, a single cable tray cover of

six feet or less in length can be installed.

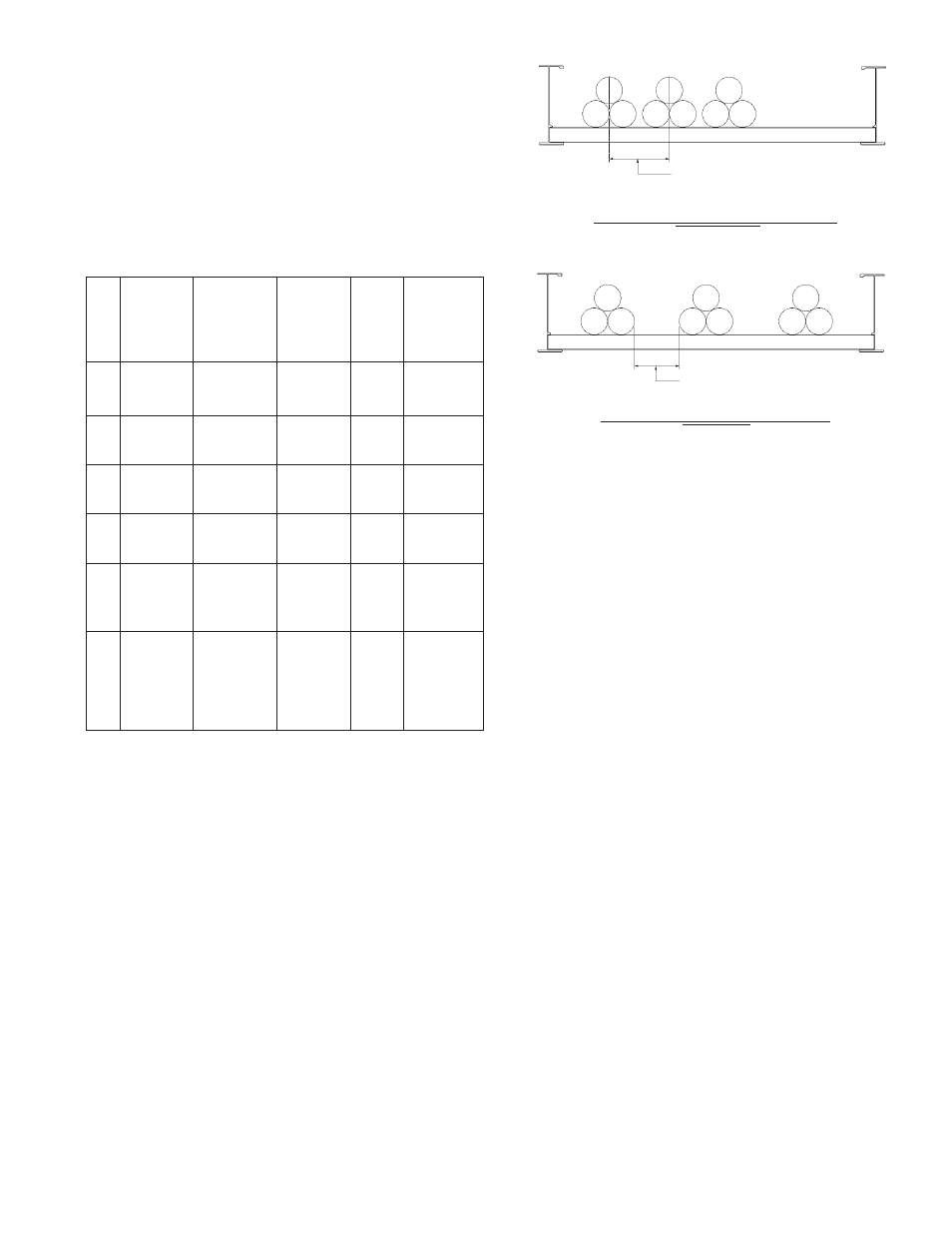

The wording of Section 392.11(B)(4) states that a spacing of

2.15 times one conductor diameter is to be maintained between

circuits. Two interpretations of this statement are possible.

Interpretation #1. - The 2.15 times one conductor diameter is

the distance between the centerlines of the circuits (the center

lines of the conductor bundles). Interpretation #2. - The 2.15

times one conductor diameter is the free air distance between the

adjacent cable bundles. The use of the word “circuit” is

unfortunate as its presence promotes Interpretation #1. An

installation based on Interpretation #1 is not desirable as a free

air space equal to 2.15 times one conductor diameter between

the cable bundles should be maintained to promote cable heat

dissipation.

Spacing Between Conductors

(2.15 x O.D. of Conductor)

Technically Desirable Installation

Spacing Between Conductors

(2.15 x O.D. of Conductor)

Technically Undesirable Installation

Interpretation #1

Interpretation #2