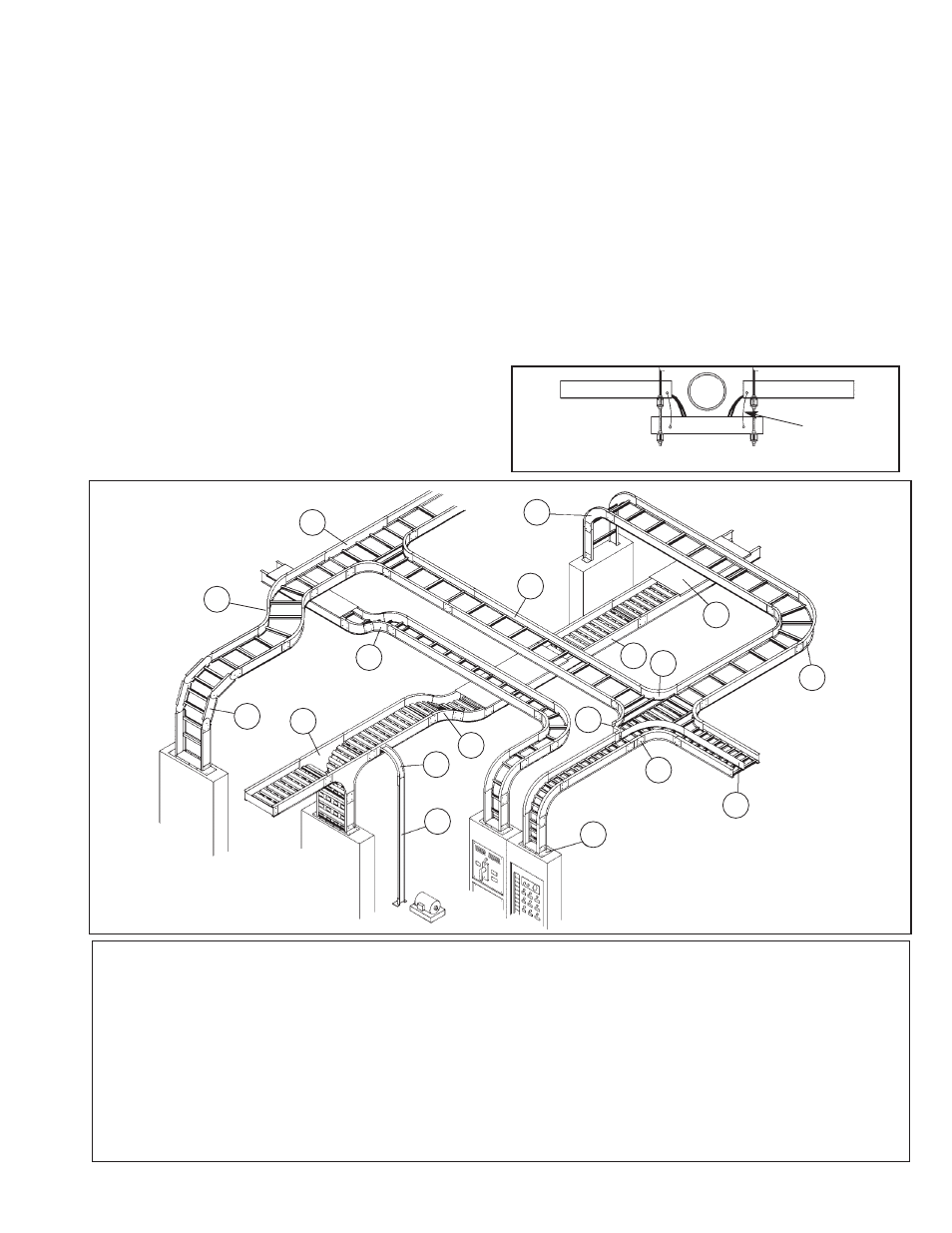

Typical cable tray layout, Installation. (a) complete system, Nomenclature – Cooper Bussmann CT02MAN User Manual

Page 23

support. Although the use of cable tray fittings is not

mandatory, it is often desirable to use them when

possible to improve the appearance of the

installation.

392.5. Construction Specifications. (F)

Nonmetallic Cable Tray.

This type of cable tray is usually made of

Fiberglass Reinforced Plastic (FRP). Applications for

FRP cable tray systems include some corrosive

atmospheres and where non-conductive material is

required. B-Line fiberglass cable tray systems are

manufactured from glass fiber reinforced plastic

shapes that meet ASTM flammability and self-

extinguishing requirements. A surface veil is applied

during pultrusion to ensure a resin rich surface and

increase ultraviolet resistance, however, for extended

exposure to direct sunlight, additional measures,

such as painting the tray, are sometimes employed

to insure the longevity of the product. Ambient

temperature is also a design consideration when

FRP cable tray is used. An ambient temperature of

100°F will decrease the loading capacity of poltester

resin fiberglass cable tray by 10%.

392.6. Installation. (A) Complete System.

This section states that cable tray systems can

have mechanically discontinuous segments, and that

the mechanically discontinuous segment cannot be

greater than 6 feet. A bonding jumper sized per

Section 250.102 is necessary to connect across any

discontinuous segment. The bonding of the system

should be in compliance with Section 250.96.

21

Cable Tray Manual

Cooper B-Line, Inc

Nomenclature

1. Ladder Type Cable Tray

10. 30° Vertical Inside Bend, Ladder Type Tray

2. Ventilated Trough Type Cable Tray

11. Vertical Bend Segment (VBS)

3. Splice Plate

12. Vertical Tee Down, Ventilated Trough Type Tray

4. 90° Horizontal Bend, Ladder Type Tray

13. Left Hand Reducer, Ladder Type Tray

5. 45° Horizontal Bend, Ladder Type Tray

14. Frame Type Box Connector

6. Horizontal Tee, Ladder Type Tray

15. Barrier Strip Straight Section

7. Horizontal Cross, Ladder Type Tray

16. Solid Flanged Tray Cover

8. 90° Vertical Outside Bend, Ladder Type Tray

17. Cable Channel Straight Section, Ventilated

9. 45° Vertical Outside Bend, Ventilated Type Tray

18. Cable Channel, 90° Vertical Outside Bend

1

2

3

4

6

7

8

10

11

12

13

14

15

16

17

18

Typical Cable

Tray Layout

5

9

Cable Tray Elevation Change Without Fittings

Bonding

Jumper