Wiring – Chromalox PN403-1 User Manual

Page 3

3

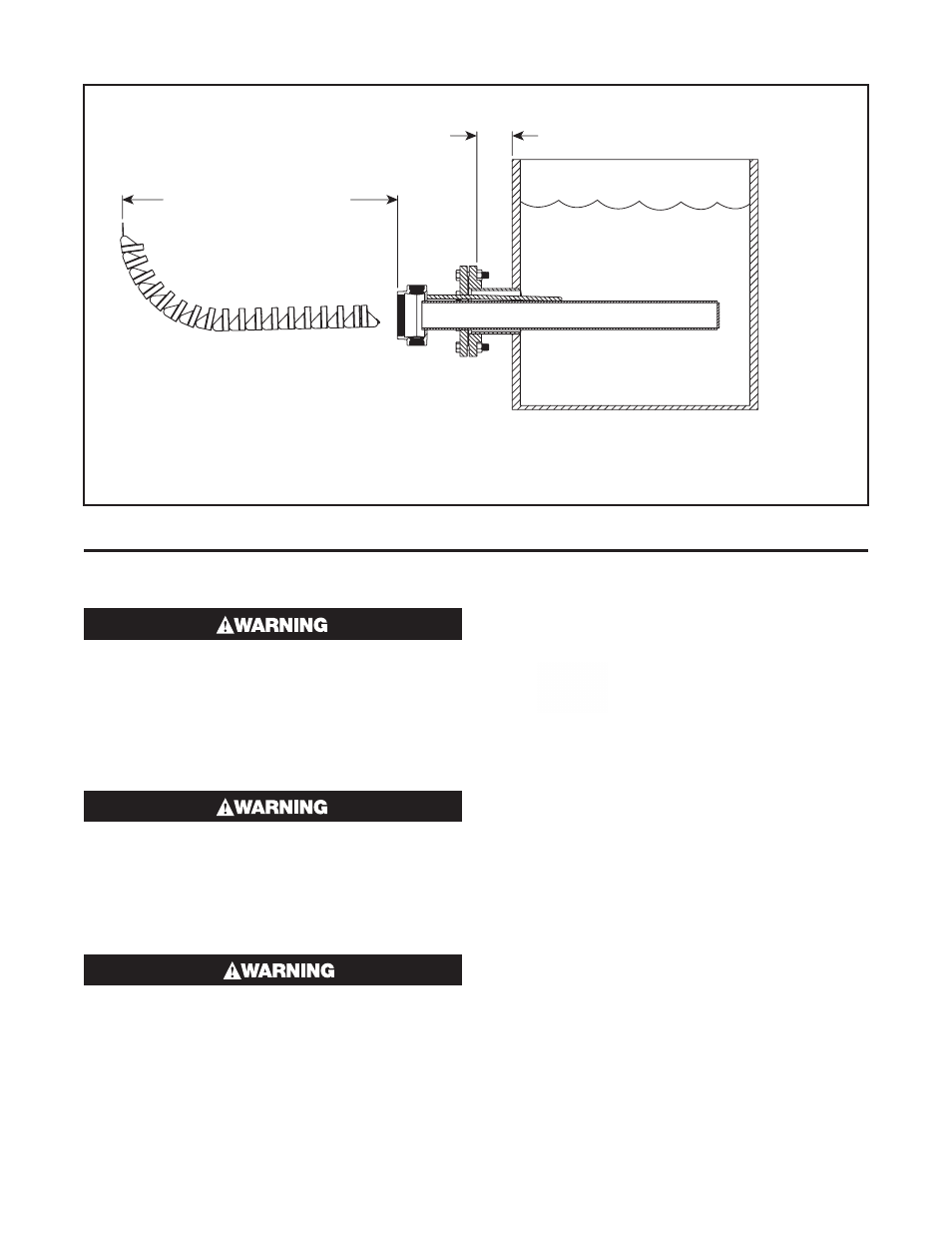

Allow for Tank

Insulation and Bolting

36” Min. Element

Removal Distance

Model LTFX

Fluid

Level

Open-Coil Elements

Figure 1

Wiring

ELECTRIC SHOCK HAZARD. Disconnect all

power before installing or servicing heater.

Failure to do so could result in personal injury

or property damage. Heater must be installed

or serviced by a qualified person in accordance

with applicable National Electric Codes, NFPA

70 and/or International Electric codes.

ELECTRIC SHOCK HAZARD. Any installation

involving electric heaters must be performed

by a qualified person and must be effectively

grounded in accordance with applicable Na-

tional Electric Codes and/or International Elec-

tric Codes to eliminate shock hazard.

The system designer is responsible for the

safety of this equipment and should install ad-

equate back-up controls and safety devices

with their electric heating equipment. Where

the consequences of failure could result in per-

sonal injury or property damage, back-up con-

trols are essential.

1. Electrical wiring to heating elements must be sized

and installed in accordance with applicable National

Electric Codes, International Electric Codes and/or

and applicable local codes by a qualified person as

defined by the code.

2. Temperatures at the heater terminals will require the

use of manganese nickel or equivalent temperature

lead wire. (Type TGS, TGT, or TGGT are recom-

mended.)

Wiring Entrance Locations - Moisture

Resistant Housing Only (E4 Option)

The Moisture Resistant (E4) Housing offers several

convenient options for conduit wiring & location. The

housing is equipped with two removable service en-

trance plates for installation of wiring. Any or all of the

six sides can be used for wiring locations. Refer to ex-

ploded view drawing. The housing can also be rotated

(by removal from flange) to allow for more position

possibilities. To install service entrance holes, simply

remove the side Allen screws and use the centering

depression to drill the appropriate size hole. Reinstall

the gasket(s), if applicable, and service entrance plates

by tightening the Allen head screws to 4-5 in/lbs. The

‘Octobox’ style of housing can be removed for ease of

access to element bussing or to better locate the pow-

er conduit(s) entry point. To accomplish, simply remove

the Allen-head screws on the outside of the housing.