Automatic water softener – EcoPure MW_MW40_450216 User Manual

Page 8

..................................................AUTOMATIC WATER SOFTENER

INSTALLATION STEPS, continued

" If making a soldered copper installation, do all sweat

soldering before connecting pipes to the softener

fittings. Torch heat will damage plastic parts.

" When turning threaded pipe fittings onto plastic fittings,

use care not to cross-thread.

" Use pipe joint compound on all external pipe threads.

" Support inlet and outlet plumbing in some manner (use

pipe hangers) to keep the weight off of the valve fittings.

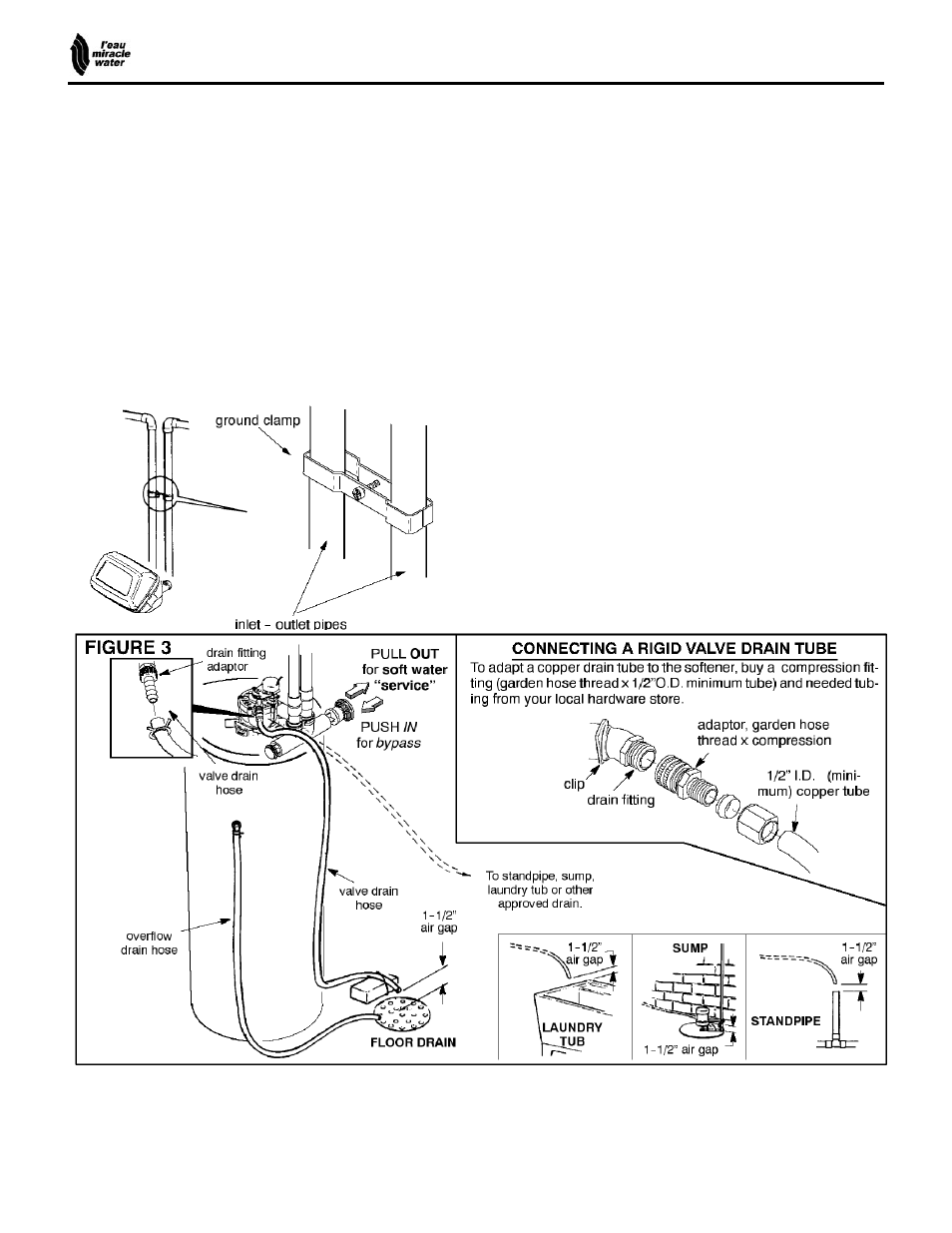

5. INSTALL GROUNDING CLAMP (IF NEEDED):

" To maintain electrical ground continuity in the house cold

water piping, install the included ground clamp as shown.

Be sure the pipes are clean under the clamps, to assure

good contact.

6. CONNECT AND RUN THE VALVE DRAIN

HOSE:

" Take a length of 5/8” inside diameter hose and attach

to the valve drain fitting.

" Locate the other end of the hose at a suitable drain

point...floor drain, sump, laundry tub, etc. Check and

comply with local codes.

IMPORTANT: If a longer length of hose is needed, buy

and use high quality, thick-wall hose that will not easily

kink or collapse. The water softener will not work if water

cannot exit this hose during regenerations.

" Tie or wire the hose in place at the drain point. Water

pressure will cause it to whip during the backwash and

fast rinse cycles of regeneration. Also provide an air gap

of at least 1-1/2” between the end of the hose and the

drain point. An air gap prevents possible siphoning of

sewer water, into the softener, if the sewer should ‘‘back-

up’’.

" If raising the drain hose overhead is required to get to

the drain point, do not raise higher than 8’ above the

floor. Elevating the hose may cause a back-pressure

that could reduce brine draw during regenerations.

continued

8