Integra LifeSciences Laparoscopic Instrument Care and Cleaning User Manual

Page 4

4

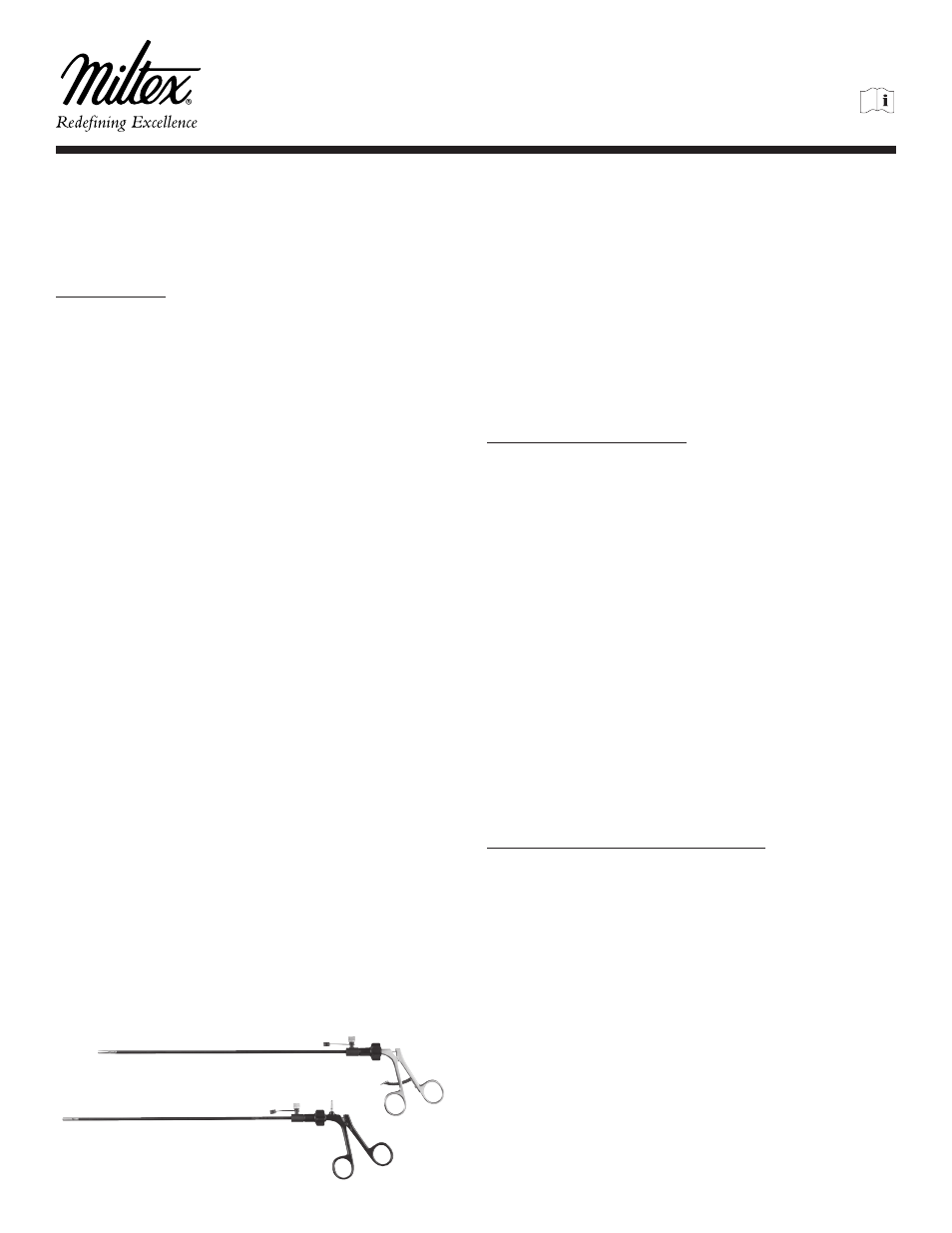

PART 2 - LAPAROSCOPIC SURGICAL

HAND INSTRUMENTS

for medical use

IMPORTANT – PLEASE READ CAREFULLY BEFORE USING

Indications for use:

Miltex

®

laparoscopic surgical hand instruments have specific

indications for use and the user should appropriately decide

whether the instrument is suitable for the desired application.

Miltex cannot provide any warranty for results due to

incorrect application.

These instructions are applicable to Miltex

®

laparoscopic

instruments and should be followed to prevent damage to

instruments. Damage resulting from instrument misuse and

improper care may void the product warranty.

Optimal function of the instruments and longer service life can

be achieved when the following instructions are observed:

• Follow instructions for proper cleaning and care of your

instruments.

• Handle the instruments with care.

• Avoid contact with other electrosurgical instruments

during use. This could result in damage to the protective

insulation coating.

• Do not bend or kink instrument sheaths.

• Make sure that insulation of instruments is not damaged

via sharp edges or other instruments during use and

during cleaning and sterilization.

• Do not drop instruments or hit against hard surfaces.

• Check function of joints and connectors regularly. Use

instruments only for the surgical purpose for which they

have been designed.

• Avoid excessive force on the instruments.

• Laparoscopic instruments should only be used by trained

and authorized personnel.

• Sterilize before use. This instrument is not provided sterile.

Stainless steel and temperature resistant plastic materials are

used in the manufacture of laparoscopic surgical instruments.

Silicone rings and washers are used as seals on sheaths and

other components.

INSTRUCTIONS FOR CARE & CLEANING OF

MILTEX

®

ENDOSCOPES AND LAPAROSCOPIC

SURGICAL HAND INSTRUMENTS

Instructions for Use/English

1. CLEANING

Immediately after each use and to prevent residual proteins

from drying on instruments, instruments should be fully immersed

in appropriate neutral-pH cleaning and disinfecting solution

recommended for reprocessing of laparoscopic surgical instruments.

Closely follow the cleaning and disinfectant manufacturer

instructions for chemical concentration and immersion time

recommendations. Plain water washing is not considered

adequate. It is recommended that fresh solutions be used

every day. Higher concentration and prolonged immersion time

may cause corrosion or other damage to the instruments.

Always avoid overnight or weekend holding or soaking.

Manual Disinfection and Cleaning:

For Manual Disinfection and Cleaning, use a soft nylon brush to

gently remove any exterior dirt and debris. Instruments are

equipped with a LUER-LOCK connection which should be

opened and force flushed using the appropriate equipment and

pressure flushing system. A water jet gun should be used on

the jaws, joints, handles and the inside of sheaths. After

cleaning and disinfection, the instruments should be

thoroughly rinsed, both on the exterior and interior sheath, with

distilled water. Immediately dry instruments to prevent

corrosion. Drying can be performed manually, but a compressed

air pistol is recommended for more delicate instruments and is

more effective for overall drying.

Thoroughly inspect instruments for effective cleaning (free

from any visible dirt and residue). Also inspect the

instruments for any damaged, worn, corroded, pitted/porous

conditions and ensure proper function. Contact Miltex if

damage is observed and if repair is necessary. Apply

non-silicone instrument lubricant (such as Miltex REF 3-700

Instrument Spray Lube) to the joints and jaws of the instrument

to ensure easy movement. Caution: Do not oil electrical

connections on instruments.

Machine/Mechanical Disinfection and Cleaning:

For Machine/Mechanical Disinfection and Cleaning, follow

equipment manufacturer’s instructions carefully. Instruments

should be stored in carriers or fixed in suitable trays which are

intended for cleaning and to prevent movement during instrument

processing. Instruments with jaws such as forceps, graspers,

scissors, dissectors and needle holders must have the jaws in

an open position before cleaning. Instruments equipped with

a LUER-LOCK connection should be opened and force

flushed using the appropriate equipment and pressure flushing

system. Distilled water is recommended to be used as the

final rinse to avoid water staining and corrosion on the instrument.

Follow equipment manufacturer’s drying cycle recommendations.

It is recommended that the interior sheath be further manually

dried via compressed air pistol to ensure effective

internal drying.