Troubleshooting – BE Pressure supply 60 Gallon Air Compressor AC5060BP User Manual

Page 19

19

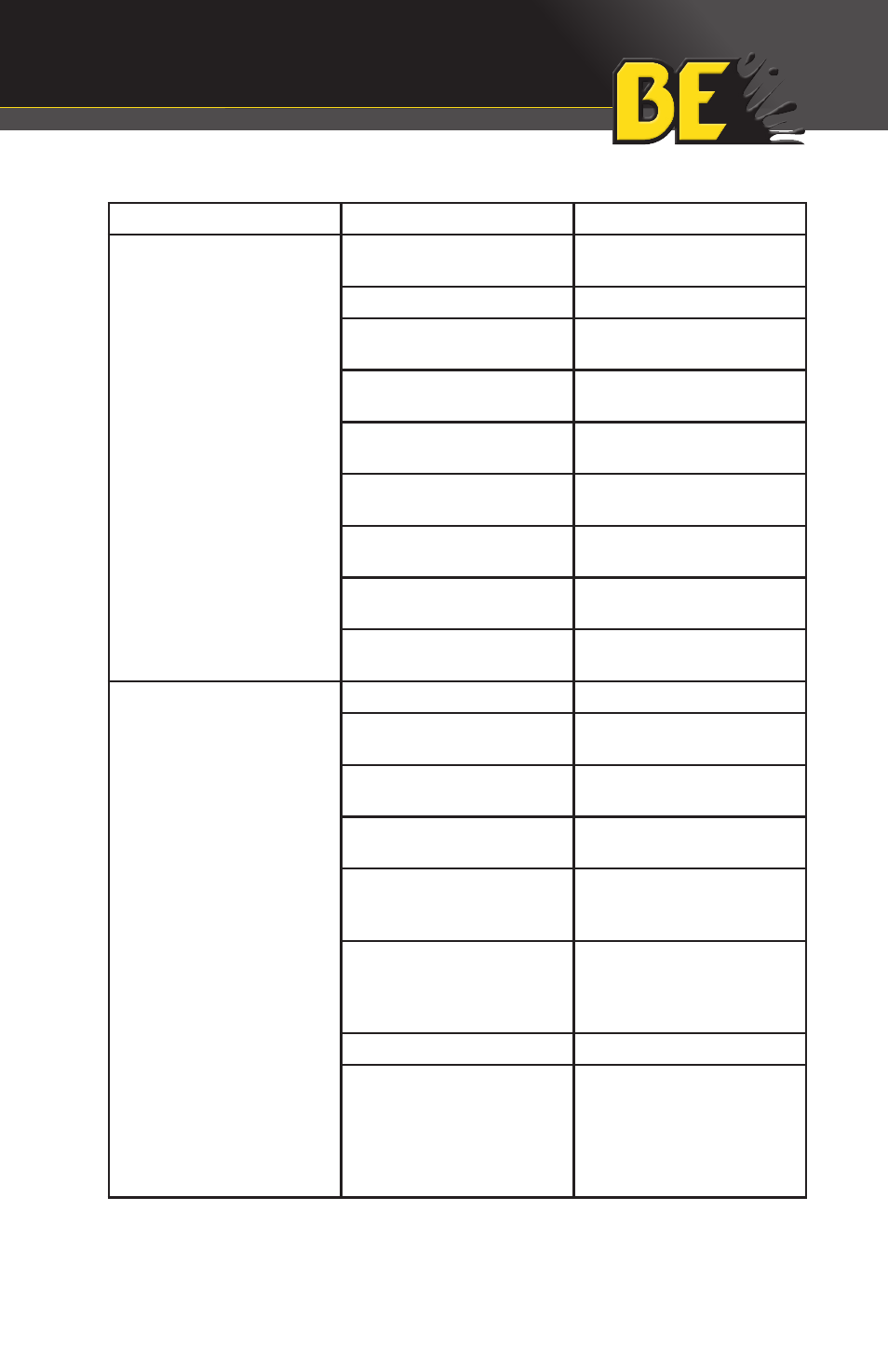

pROBLEM

pROBABLE CAUSE

CORRECTIVE ACTION

Excessive vibration /

compressor knocks

Loose compressor, motor

or engine guard.

Tighten components.

Compressor not level.

Level compressor

Feet bolts over tightened to

floor.

Loosen feet bolts.

Excessive discharge

pressure.

Reduce operating pressure.

Wrong oil being used.

Drain and replace with

proper oil.

Loose flywheel, drive, pulley

or drive belts.

Tighten loose components

and check belts.

Worn connector rods, wrist

pin or main bearings.

Check and replace worn

parts.

Compressor valves loose or

broken.

Check and replace worn or

broken valves..

Check valve knocks at low

pressure.

Remove and clean check

valve.

Compressor uses too

much oil

Clogged inlet filter.

Replace check valve.

Wrong oil being used,

wrong viscosity.

Clean inlet filter or replace

as necessary.

Oil level too high.

Fill compressor with oil to

proper level.

Crankcase breather valve

malfunction.

Replace crankcase

breather.

Compressor runs unloaded

too long

Increase load or stop

compressor when not

needed. Check for air leaks.

Compressor operating

outside in cold conditions

or inlet filter not protected

against weather.

provide adequate

protection against extreme

weather conditions.

Worn piston rings.

Replace piston rings.

piston rings

not seated.

Allow 100 hours of normal

operation for new rings to

seat.

Drain oil and refill with

Eagle EAOIL oil or other

approved oil.

troubleshooting