Troubleshooting – BE Pressure supply 60 Gallon Air Compressor AC5060BP User Manual

Page 18

18

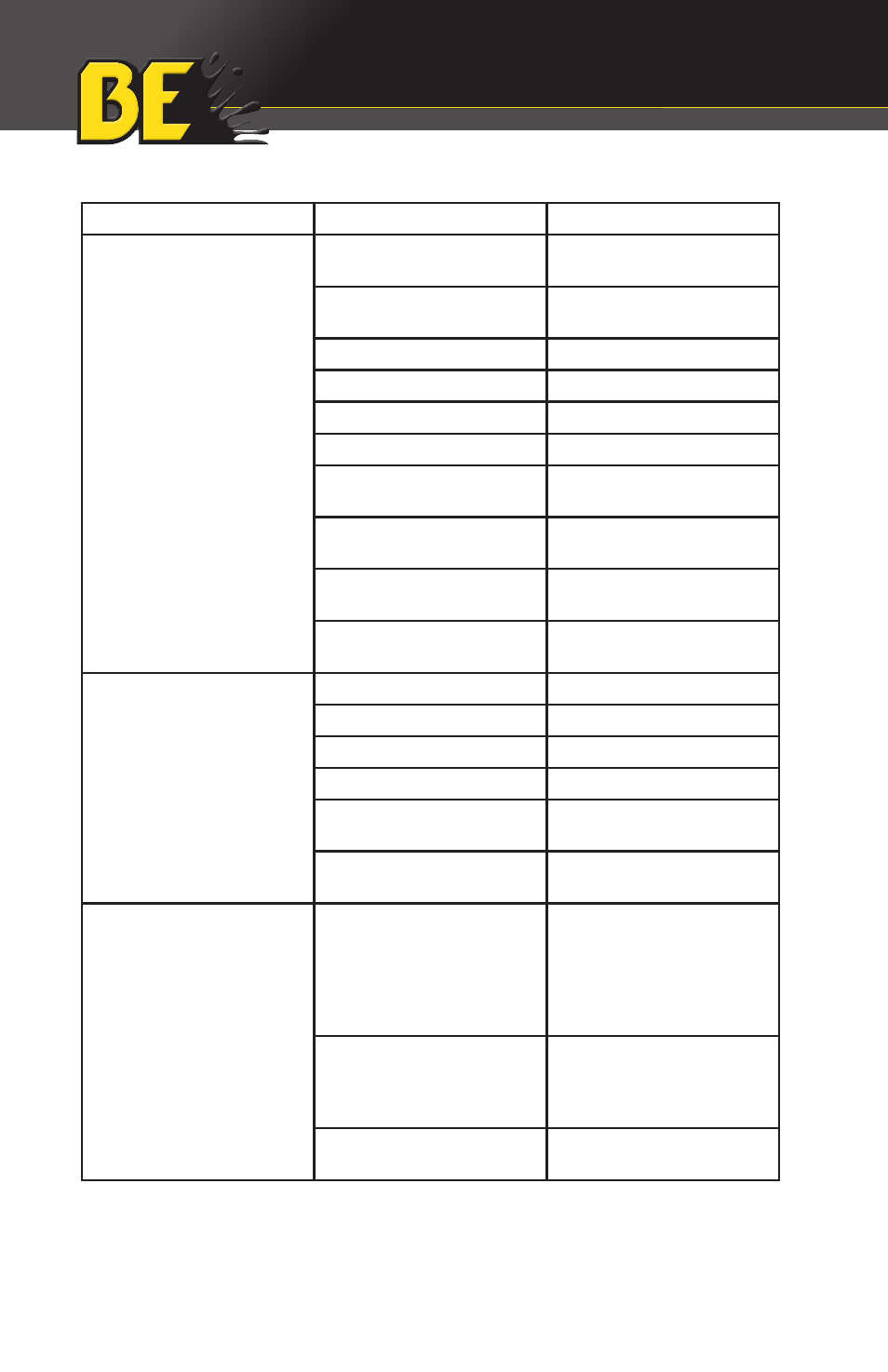

pROBLEM

pROBABLE CAUSE

CORRECTIVE ACTION

Insufficient output, low

discharge pressure

Clogged inlet filter.

Clean or replace as

necessary.

Leaks in air lines, air valves,

fittings, etc...

Replace worn components

as necessary.

Drive belts slipping.

Tension V-belts.

Drain valve left open.

Close drain valve.

Defective pressure gauge.

Replace pressure gauge.

Leaking head gasket.

Replace head gasket.

Dirty or plugged inter cooler

tubes.

Remove and clean inter

cooler tubes.

pressure switch adjusted

too low, or defective.

Make necessary

adjustments.

Worn or defective

compressor valves.

Replace valves.

Worn piston, worn out

rings.

Replace worn parts.

Motor stalls or blows

breaker

Faulty check valve.

Replace check valve.

Valves incorrectly installed

Install valves correctly.

Drive belts too tight.

Tension V-belts.

Defective pressure switch.

Replace switch.

Defective Motor.

Replace Motor. (Consult

licensed electrician).

power being supplied by

generator.

Consult licensed electrician

Water in crankcase oil

gets dirty, rusty valves or

cylinders

Cycle too short;

compressor does not

operate long enough

to vaporize condensed

moisture during

compression.

Allow for longer operating

cycle.

System pressure leaking

back through check valve

when compressor is

stopped.

Check and replace check

valve if necessary.

Wrong oil being used.

Drain and replace with

proper oil

troubleshooting