9 depth control, 10 using shims – Great Plains Simba SL700 Operator Manual User Manual

Page 26

26 Simba SL700

603-216M-ENG

2013-01-25

4.9 Depth Control

Working depth can be set by rear roll and

front depth wheels. Under normal conditions

the weight of the machine will be carried on

the roll and the front depth wheels, with the

main lift wheels either fully up or floating.

If the wheels are powered up, then placed

in float the axle will hold up until powered

down. Depth is set using the depth control

cylinders situated on the roll unit with shims

added and removed as appropriate, and with

the adjusters on the front wheels, which are

adjusted using the square spanner provided.

The front to rear pitch of the machine should

be adjusted as appropriate to compensate

for changes in working depth by adjusting

the height of the depth wheels.

Using the Rear Roll

Use roll depth adjuster/hydraulic cylinder to

set machine working depth. The front depth

wheels should be adjusted to suit the depth

of the rear roll ensuring that the chassis runs

level front to rear.

4. Adjustment / Operation

4.10 Using Shims

Before using shims to alter machine settings

ensure the machine is stationary and the

tractor is turned off with the keys out. Ensure

that all operators are clear of the machine

and that no load is being held on any existing

shims in the cylinder / depth control rod.

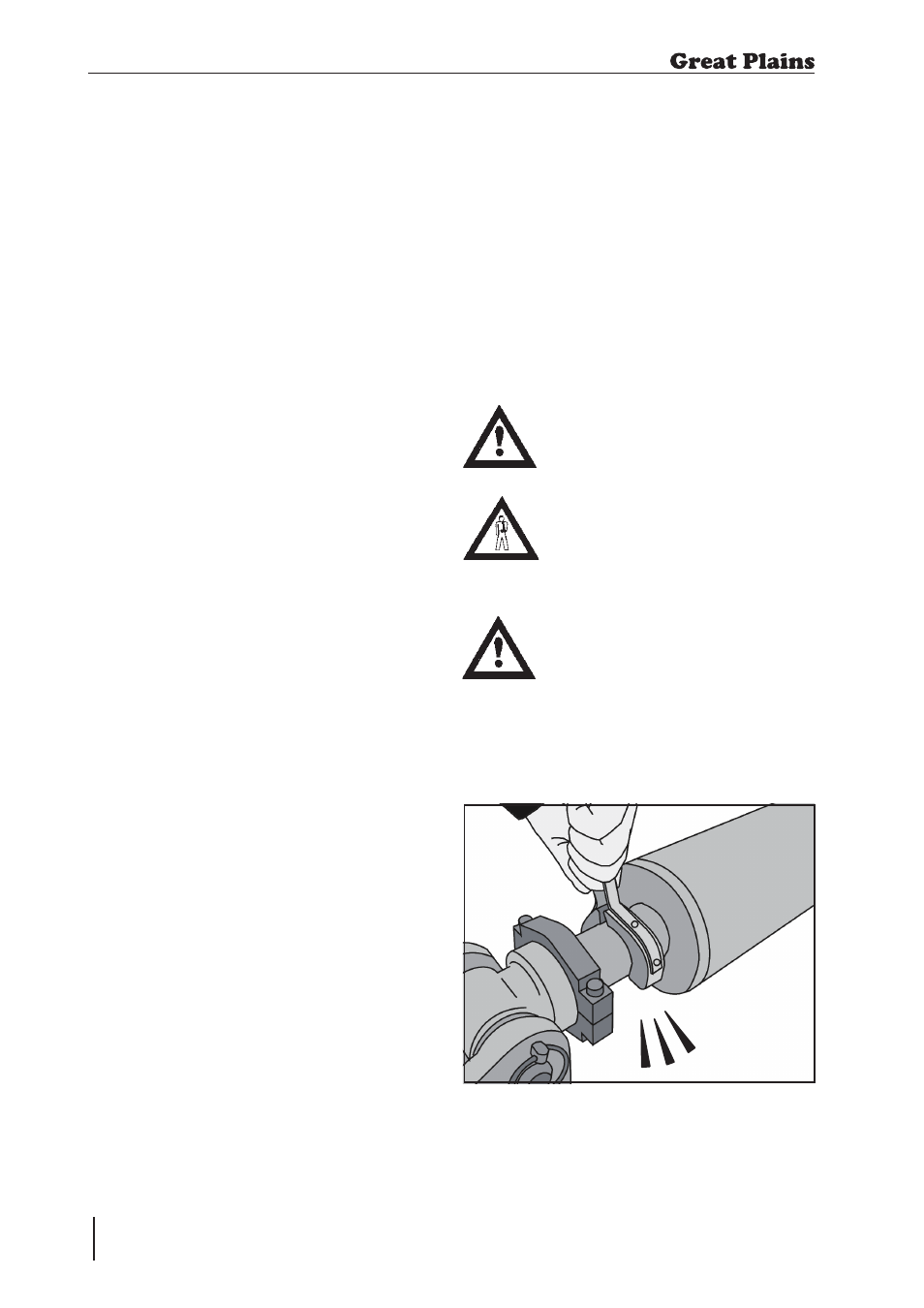

To fit the shims hold them by the handle and,

using a firm action, clip them onto the rod

as shown in Fig. 4.08. They are removed by

using a finger to pull firmly on the handle.

Check the cylinder / depth control

rod for damage and debris before

fitting shims.

Only attempt to add or remove

shims using the handle. Trying to

manipulate shims using the jaws

could result in injury.

When changing machine settings

ensure both sides of the machine

mirror each other. The left hand

cylinder should contain the same

amount of shims as the right, for

example. Failure to do this could

result in damage to the machine.

Fig. 4.08: Shims