Transport cylinders, 8 starting settings, 7 work settings – Great Plains Simba SL700 Operator Manual User Manual

Page 24

24 Simba SL700

603-216M-ENG

2013-01-25

1x

Silver

51mm

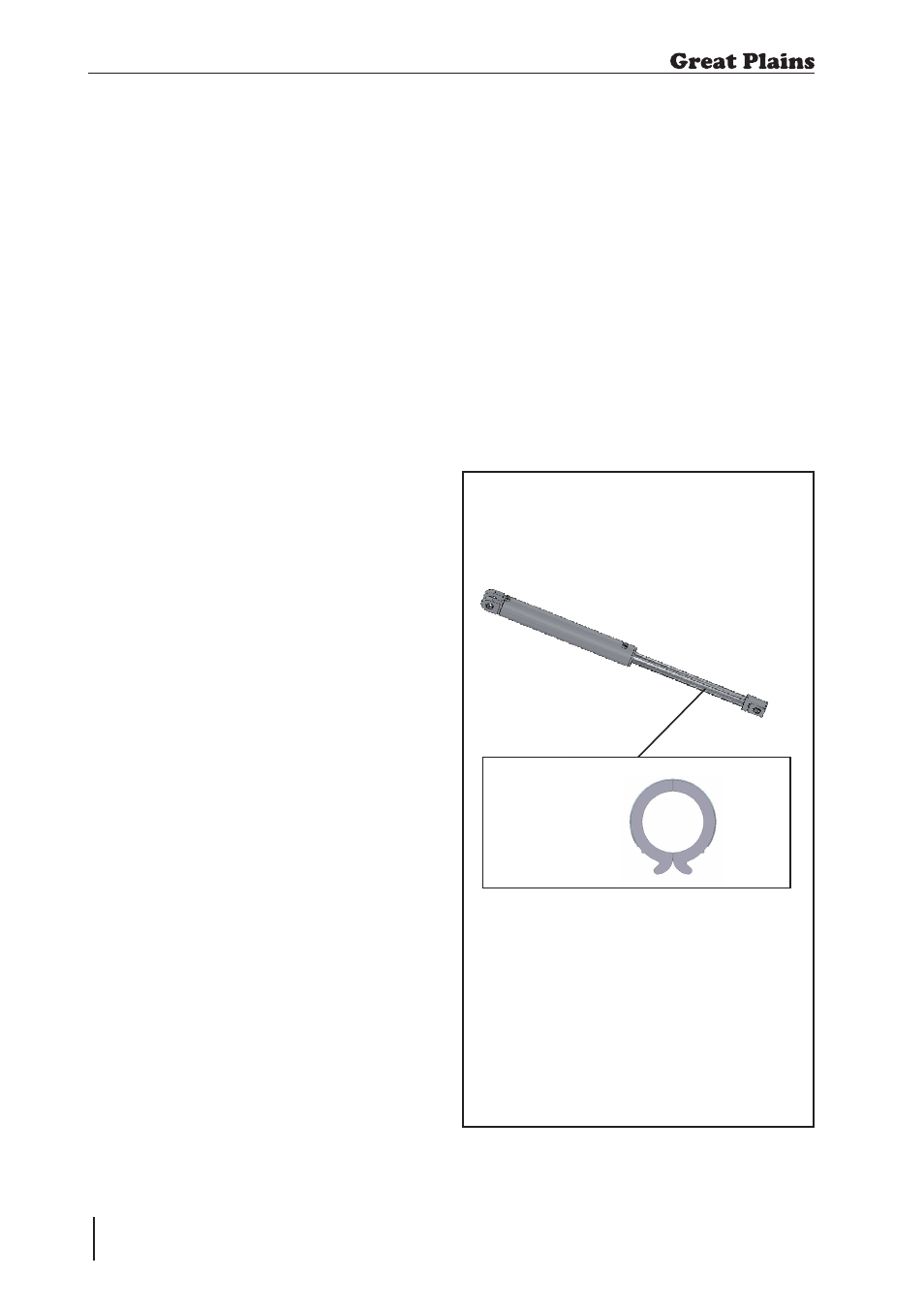

Transport Cylinders

(in road transport)

4.8 Starting Settings

This section details the recommended

starting settings for the SL700. These

settings can then be used as a base for

further adjustment in order to get the

optimum performance from your machine.

Ensure all settings from the left and right

hand sides of the machine match each other.

4.7 Work Settings

In work the wing cylinders should be fully

extended. A simple pressurised hydraulic

circuit automatically sets itself as the wings

are unfolded.

Optimum performance has been found

to be achieved when the press roll rings

have worn away the painted finish leaving

a smooth shiny surface. When the press

roll rings are new or rusty, soil may tend to

pick up on the surface and blockage may

occur, this will reduce when the rings are

shiny again.

The SL700 should be run with the chassis

level. In normal operation the machine

should be carried between the rear roll and

front depth wheels with the lift circuit in float.

In practice it is possible to use the SL700

on ground conditions that are unsuitable to

achieve the desired effect, and it is usually

possible to operate without regular blockage

under such unsuitable conditions, assuming

that the axles are tight and rings smooth. As

such, especially under wet conditions, it is

advisable to check on the cultivation effect

of the SL700.

Generally a forward speed of 5-7 mph

(8-11 kph) will achieve optimum results,

maximising inversion and burial. Speeds

in excess of those stated above will tend

to give a deterioration in the quality of the

work. This may be seen as a ridge and

trough effect across the work surface due

to soil being thrown too far by the leading

discs, the rear discs then are unable to turn

enough soil back.

It may occasionally be useful to almost fill

the drawbar cylinder with shims to allow

the drawbar to momentarily take the weight

if the front wheels pass over any low/soft

areas in the soil profile while maintaining

forward speed and traction. If using the

In normal operation a 51mm shim

should be left in place at all times except

in situations where an extremely low

transport height is required (ie when

transporting on a lorry). On machines

fitted with a following harrow no shims

are needed here.

4. Adjustment / Operation

machine without the front depth wheels

(in changeable conditions, for instance)

it should be hydraulically drawn onto the

drawbar shims.