Operating whirlfilter, Manual elevator option, Transporting – Great Plains TA520S Operator Manual User Manual

Page 26

1993-1995 Tandem Axle Sprayer

500-061M

3/18/2005

24

Operating Whirlfilter

®

There are two Whirlfilters

®

on your Great Plains Sprayer.

One filters the water entering the tank and the other fil-

ters the chemical solution being sprayed.

To clean-out the solution Whirlfilter

®

, proceed with

the following:

1.

Fill the sprayer tank with water and turn the pump

on.

2.

With the pump running, slowly open the clean-out

valve and allow the grit to flow out into a bucket.

Clean out the solution Whirlfilter

®

only when the

sprayer tank is filled with water and no chemical has

been added.

3.

Close the clean-out valve and turn off the pump.

4.

Dispose of the grit and water in the same manner

described on the manufacturer’s label of the latest

chemical used in the sprayer.

To clean out the tank-fill Whirlfilter

®

, proceed with

the following:

1.

Start with an empty sprayer tank.

2.

Position a bucket under the plug in the sump of the

Whirlfilter

®

and allow the grit to fall out.

3.

Screw the plug back in using pipe thread sealant to

seal the plug.

4.

Dispose of the grit and water in the same manner

described on the manufacturer’s label of the latest

chemical used in the sprayer.

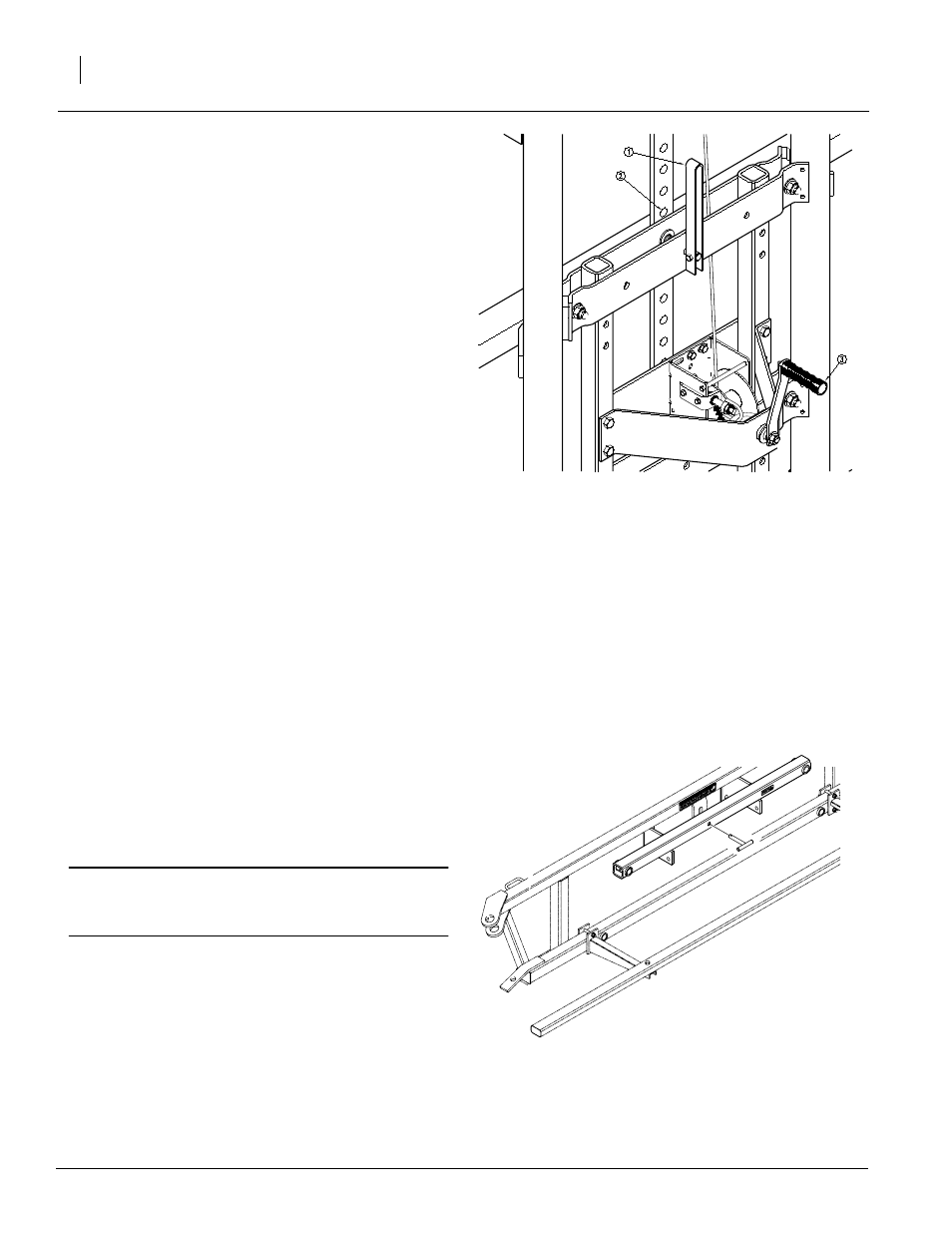

Manual Elevator Option

Refer to Figure 12

1.

Crank the winch handle (3) clockwise 1/4 of a turn or

until the weight is supported by the cable

IMPORTANT! DO NOT crank the winch too far with

the lock pin locked. To do so may break the cable or

damage the elevator.

2.

After the weight is supported by the cable, you

should be able to pull the lock handle (1) out easily.

Pull the lock handle out and leave it sticking out with

the lock pin removed from the lock hole (2).

3.

Crank the winch to the desired boom height.

4.

Push the lock handle down to lock the pin into a lock

hole (2). Crank the winch until the lock pin snaps into

the hole.

Transporting

Refer to Figure 13

1.

Park your sprayer in an open area where you will not

hit power lines, buildings, etc. when the boom is fold-

ed.

2.

Secure the level-float pin in the lock position.

Figure 13

Level Float Pin In Lock Position

Figure 12

Elevator Winch Illustration

11566

12005