Pre-assembly preparation, Notations and conventions, Tools required – Great Plains 3PYP Planters User Manual

Page 2: Work location, Prepare implement

2

Great Plains Manufacturing, Inc.

Front Page

Part Lists

Steering Upgrade

401-640M

Front Page

Part Lists

08/11/2010

Notations and Conventions

Call-Outs

Pre-Assembly Preparation

Tools Required

• Updated operator and parts manuals (see page 1)

• suitable tractor for raising implement

• oil spill clean-up materials

• basic hand tools

• light colored tape and indelible marker for identifying

hydraulic hoses

Work Location

1.

Move the implement to a location with:

Prepare Implement

2.

Raise the planter.

3.

Install transport locks.

4.

Lower parking stands.

5.

Set all remote hydraulic ports to Float.

6.

Unhitch.

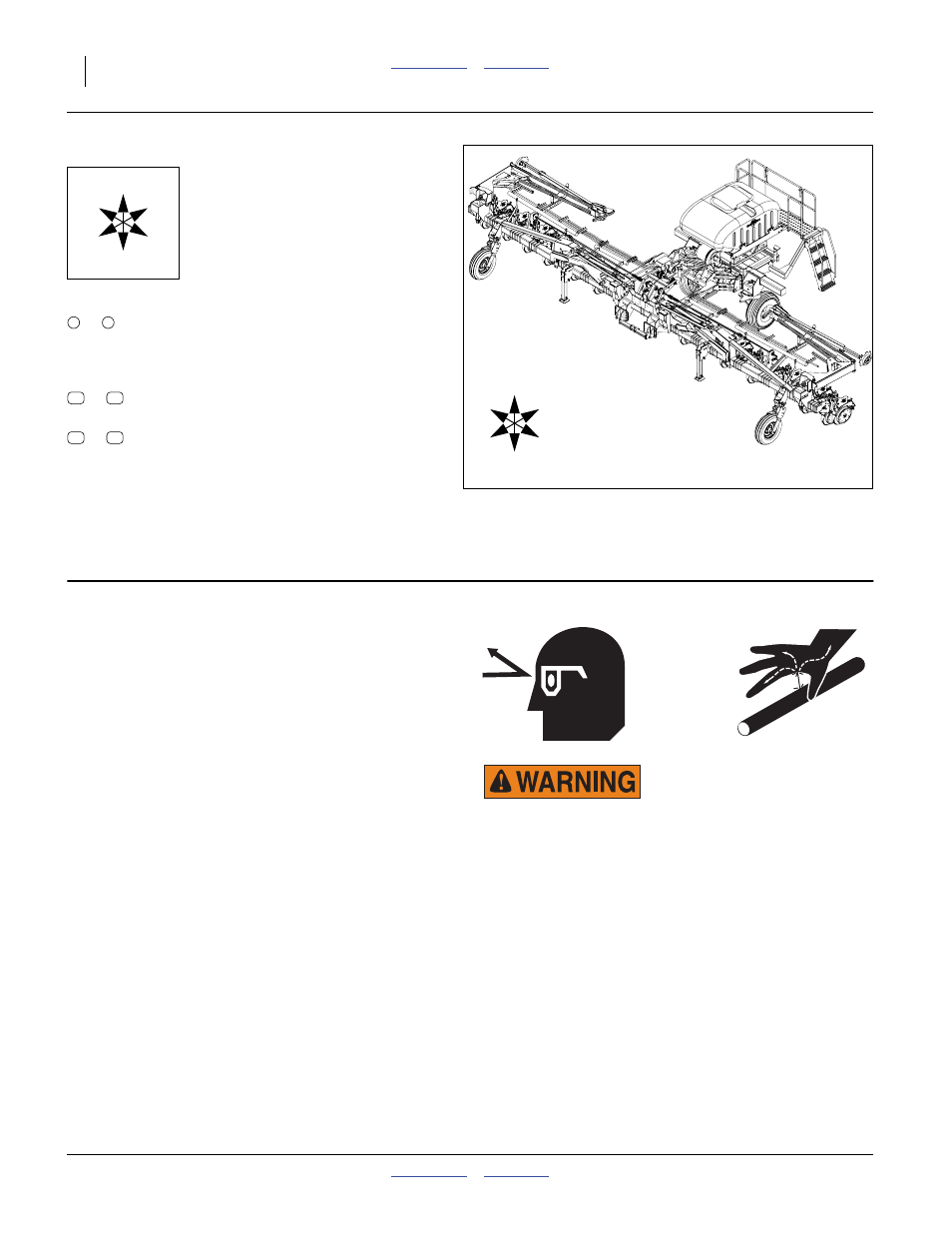

“Left” and “Right” are facing in the

direction of machine travel. An orienta-

tion rose in the line art illustrations

shows the directions of Left, Right,

Front, Back, Up, Down.

to

Single-digit callouts identify components in

the currently referenced Figure. These num-

bers may be reused for different items from

page to page.

to

Two-digit callouts in the range 11 to 50 refer-

ence new parts from the list on page 11.

to

Two-digit callouts in the range 51 to 54 refer-

ence existing parts from the list on page 12

• flat, smooth surface

• adequate illumination

• clear surface beneath for recovery of any falling or

dropped parts

Figure 1

3PYP Planter

25050

U

D

F

B

L

R

U

D

L

R

B

F

1

9

11

50

51

54

High Pressure Fluid Hazard:

Releive pressure from all lines before working on hydraulic

connections. Wear eye protection and gloves when opening

hydraulic connections. Open connections slowly. Use a piece

of paper or cardboard, NOT BODY PARTS, to check for leaks.

Escaping fluid under pressure can have sufficient pressure to

penetrate the skin causing serious injury. If an accident

occurs, seek immediate medical assistance from a physician

familiar with this type of injury.