Mounting wheels, Test and adjust brakes, Mounting wheels test and adjust brakes – Great Plains DVN8324 Operator Manual User Manual

Page 59

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

55

11/25/2013

550-466M

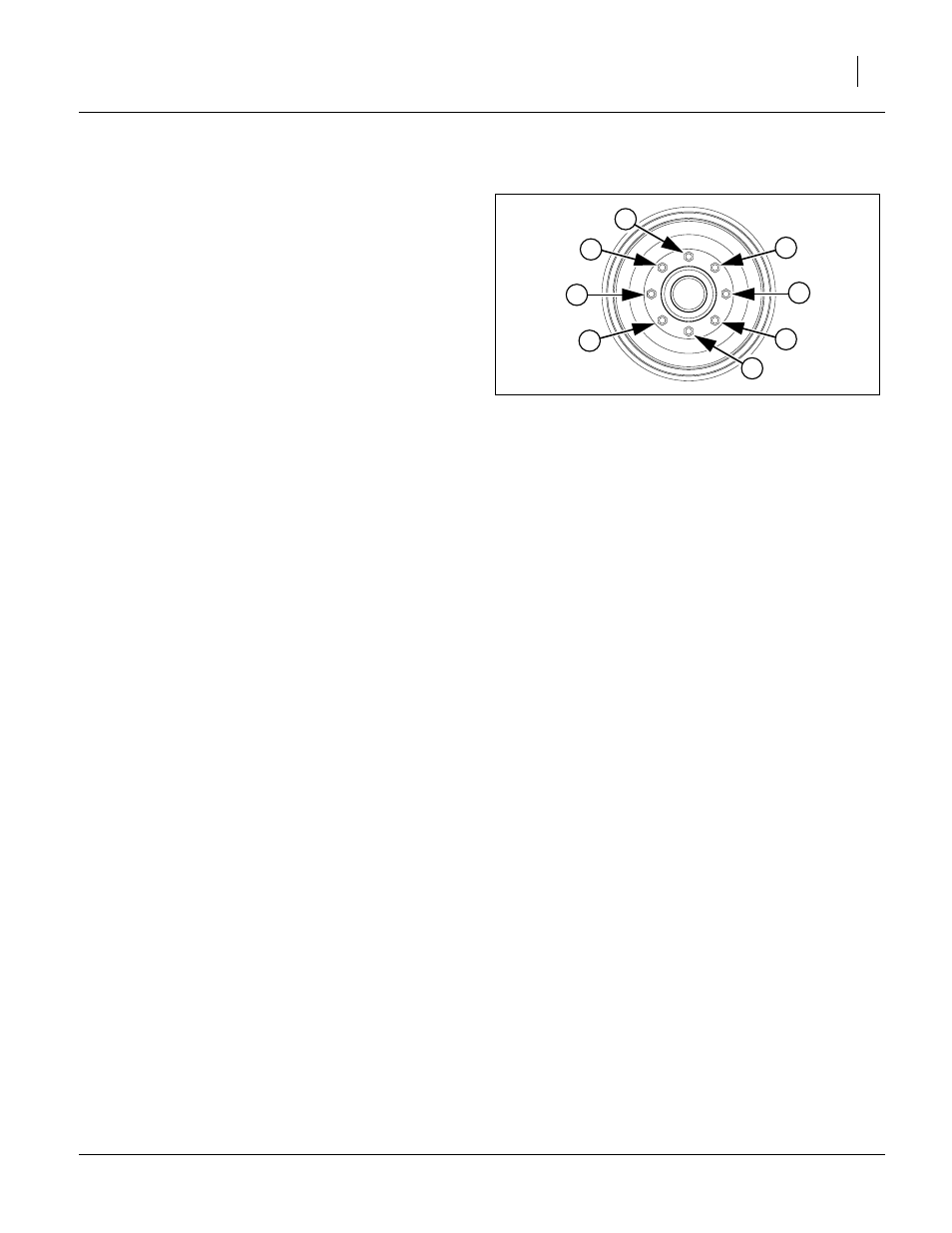

Mounting Wheels

55. Position a wheel on the hub from which it was dis-

mounted.

Refer to Figure 55

56. Start all lug nuts by hand. Choose a bolt stud to des-

ignate position #1.

57. Torque in stages, setting each lug nut to the speci-

fied torque in the order shown in the figure:

Stage 1: 27-33 N-M (20-25 ft-lbs)

Stage 2: 74-80 N-M (55-60 ft-lbs)

Stage 3: 114-127 N-M (85-95 ft-lbs)

Note: This staging and ordering of tightening is strongly

recommended to ensure that the drum is not driven

out-of-round.

58. Repeat step 56 and step 57 for each wheel.

Test and Adjust Brakes

While the machine axle is still elevated, test both the ser-

vice and the parking brake systems.

59. Hitch a tractor equipped with trailer brake remote.

Connect the braking systems. Put the tractor in Park,

but release any brakes that operate the trailer ser-

vice brakes.

60. Have someone spin one brake-equipped machine

wheel, and stand clear.

61. Slowly engage the tractor service brakes. If the

wheel does not stop spinning, this may merely indi-

cate that the self-adjusters have not yet seated.

Cycle a second time.

62. Check for unusual noises and failure to brake. Check

that the wheel spins freely with brakes released.

63. Spin another machine wheel. Stop it with the tractor

brakes. Check braking action. The self-adjusters

may already be seated for this and the remaining

wheels.

64. Release all tractor braking that engages machine

braking.

65. Spin the first wheel again. Engage the machine park-

ing brake for that side. With fresh brake linings, it

may be necessary to adjust the hand brake handle to

achieve over-center brake-set detent with acceptable

effort.

66. Spin and test brake the other wheel on that side.

67. Repeat step 65 and step 66 for the other side of the

machine.

68. Check tire inflation, set parking brakes, and lower

machine onto its own wheels.

Figure 55

Bolt Torquing Pattern

29645

3

7

5

2

4

8

6

1