Maintenance and lubrication – Great Plains DVN8324 Operator Manual User Manual

Page 47

11/25/2013

550-466M

Great Plains Manufacturing, Inc.

43

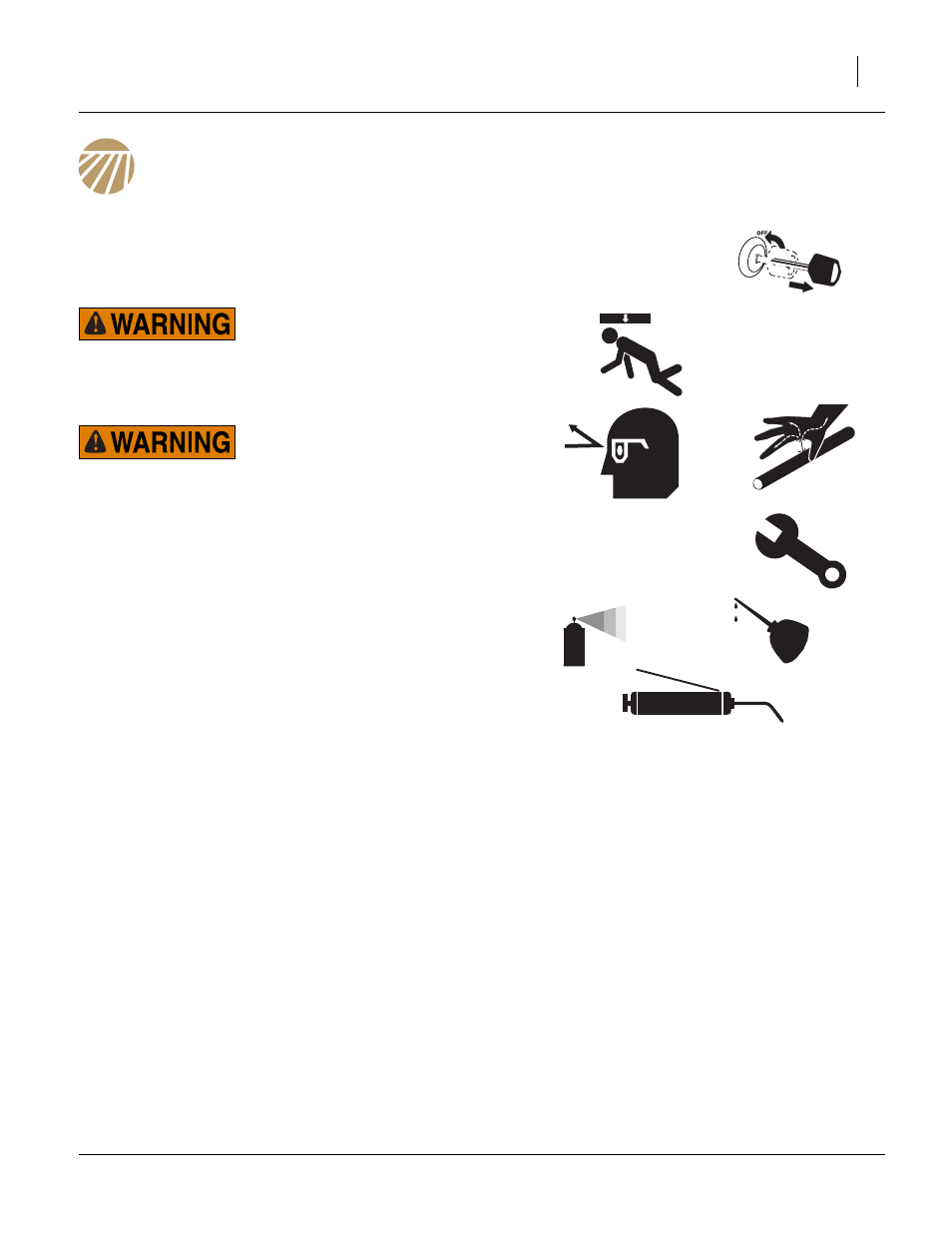

Maintenance and Lubrication

Proper servicing and maintenance is the key to long imple-

ment life. With careful and systematic inspection, you can

avoid costly maintenance, downtime and repair.

Always turn off and remove the tractor key before making any

adjustments or performing any maintenance.

Crushing Hazard:

You may be severely injured or killed by being crushed under a fall-

ing implement. Always use transport locks when working near or

under a raised implement.

High Pressure Fluid Hazard:

Escaping fluid under pressure can have sufficient pressure to pene-

trate the skin. Check all hydraulic lines and fittings before applying

pressure. Fluid escaping from a very small hole can be almost invis-

ible. Use paper or cardboard, not body parts, and wear heavy

gloves to check for suspected leaks. If injured, seek immediate medi-

cal attention from a health care provider familiar with this type of

injury.

After using implement for several hours, check all bolts to be

sure they are tight.

1.

Securely lock up implement before working on it.

2.

Lubricate areas listed under “Lubrication and Sched-

uled Maintenance” on page 45.

3.

Check for air leaks at hose connections.

4.

Check and tighten or replace any hydraulic leaks. Check

hoses for any leaks. It is important that there are no leaks

on the equipment.

5.

Inflate tires as specified on “Tire Inflation Chart” on

page 64.

6.

Replace any worn, damaged or illegible safety

decals. Order new decals from your Great Plains

dealer. “Safety Decals and Lights” on page 10.

7.

During the first season of operation, and periodically

after that, check your bolts for tightness. Check

shank pivot bolts for tightness. Check shank pivot

bolts on the spring-loaded shank, these must remain

tight to prevent excessive wear on the shank assem-

bly.

8.

Replace or rotate worn parts as needed -- hinge

bolts, clevis pins, bearings, sweeps, shanks, etc.

Boron disc blades cannot be rolled to sharpened,

they must be ground. Cracks and breakage will

occur if rolled.

9.

Grease wheel bearings and walking beams spar-

ingly. Over greasing may cause damage to seals and

reduce the life of the bearing. Grease hinge points

periodically.

10. Check drag bolts for loosness or excessive wear.

Replace broken or bent teeth. Your drag is an impor-

tant part of the tillage operation.

11. If machine is stored outdoors over the winter months,

it is a good idea to fold the machine then set it down

on the ground so all the cylinders are retracted to

protect the cylinder rods. This will extend the life of

the cylinder seals and reduce internal and external

leaks.