Marker transport carrier, Seed box maintenance, Main box cleanout – Great Plains 2510HDF Operator Manual User Manual

Page 57

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

53

2013-11-11

288-340M

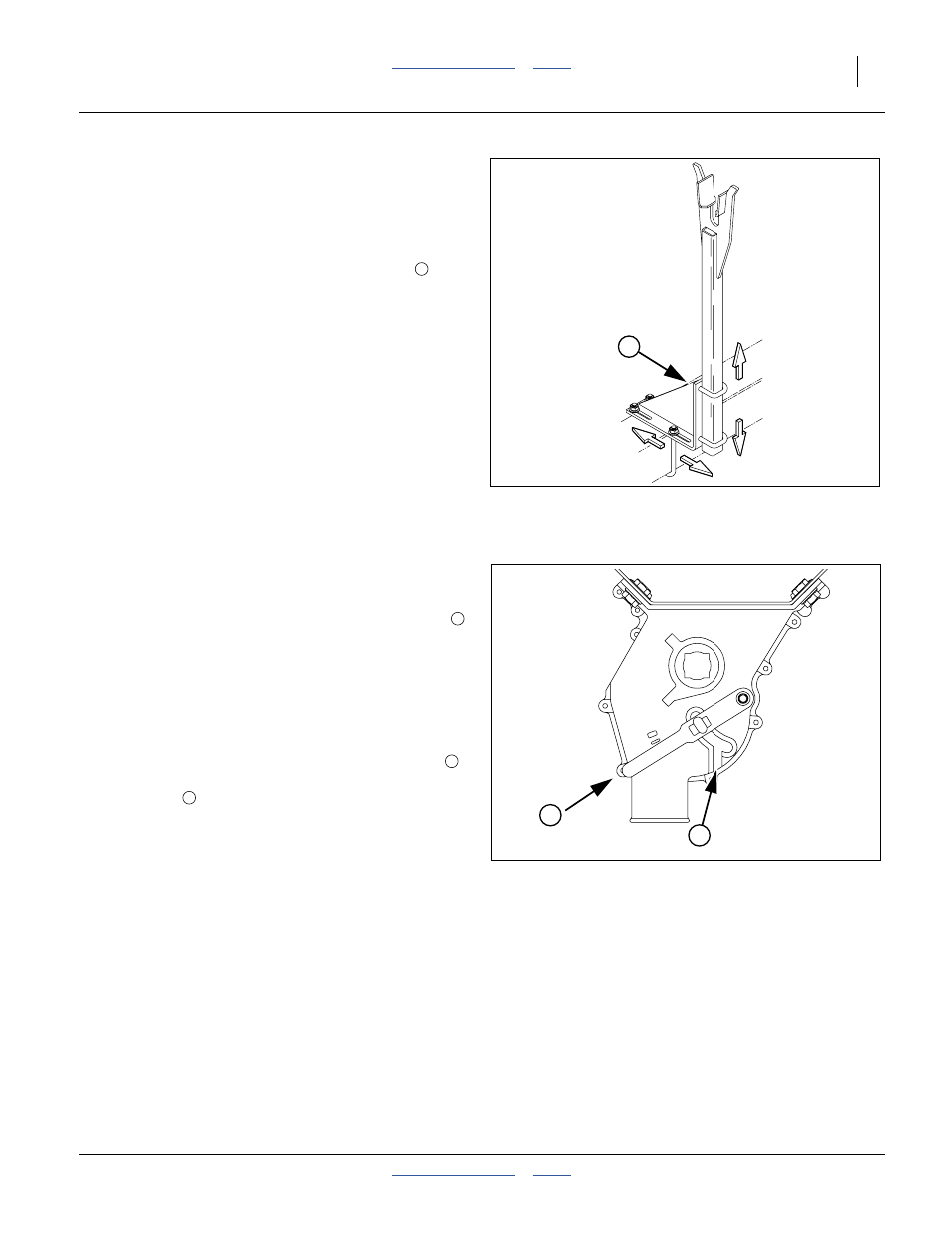

Marker Transport Carrier

When marker is folded, the second section should be

centered in transport carrier saddle and be parallel with

top of drill box.

Refer to Figure 50

To adjust height of saddle, loosen

1

⁄

2

x2in U-bolts

that

hold carrier tube to mounting bracket. Slide carrier tube

up or down as needed.

Seed Box Maintenance

Main Box Cleanout

Refer to Figure 51, which depicts the seed cup door handle

in a normal operating position

.

1.

Set the Seed Rate Handle to zero (0) for the section

of the drill to be cleaned out. This moves the seed

cup sprockets out of the seed path.

2.

Position a tarp or bucket under each row or set of

rows to be cleaned out.

3.

At the seed cup for that row, pull the door handle

out of the operating detent range, and swing it down

to position

.

4.

Open the main seed box and use a small brush to

sweep seed toward seed cups set to clean-out. If

seed does not flow freely, inspect seed cup, hose

and seed tubes for obstructions.

5.

Wash out the seed box with high pressure water.

Prop the lid slightly open until dry.

It is not necessary to operate the seed meter drive shaft

for clean-out. With the Seed Rate set to zero, nothing

moves inside the seed cups; however, an inspection of

the flutes for excess wear and damage does require

shaft rotation.

Set the Seed Rate Handles to 100. With openers raised,

each gauge wheel can be slowly turned by one person,

while another inspects the flutes from the open seed

boxes.

Figure 50

Marker Transport Carrier

15632

1

1

Figure 51

Seed Cup Cleanout

26211

1

2

1

1

2