Field operation, Shaft monitor operation, Field operation shaft monitor operation – Great Plains 2510HDF Operator Manual User Manual

Page 30

26

1510HDF/2010HDF/2510HDF

Great Plains Manufacturing, Inc.

288-340M

2013-11-11

Field Operation

Crushing Hazard: You may be severely injured or killed by

being crushed between the tractor and drill. Do not stand or

place any part of your body between drill and moving tractor.

Stop tractor engine and set park brake before installing pins.

1.

Hitch drill to a suitable tractor or hitch. See “Hitch-

ing” on page 12, or your hitch operator’s manual.

2.

Set and calibrate seeding rate as explained at

“Material Rate Adjustments” starting on page 30.

Check that meter rates and seed-cup-door handles

are set the same across the drill.

Note: If you notice excessive cracking on large seeds, ad-

just all seed-cup doors to a wider setting. Use the

widest setting only for seed-cup clean out.

3.

Setup row units for desired down-force and planting

depth. See “Row Unit Adjustments” on page 40.

4.

Enable or disable seed firmers as desired.

5.

Load seed box with clean seed. Load fertilizer if

used. Fold up ladders.

6.

Record acremeter readout. Subtract initial reading

from later readings to determine area drilled.

7.

Pull forward, lower drill, set 3-point circuit to Float,

and begin seeding.

8.

Always lift drill out of the ground when turning at row

ends and for other short-radius turns. Seeding stops

automatically as drill is raised in the field.

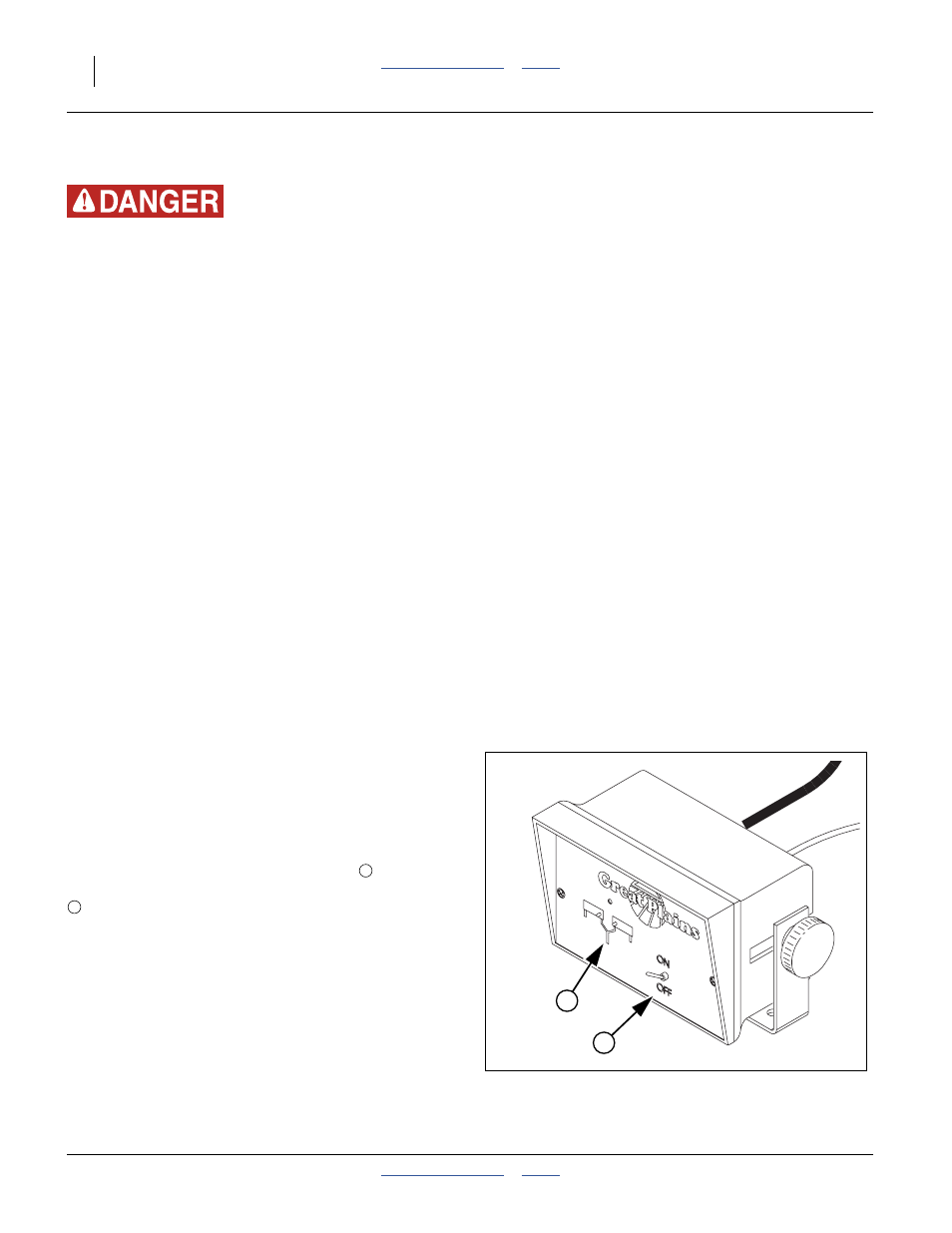

Shaft Monitor Operation

The optional shaft monitor generates an alarm if either of

the two main seed box meter shafts on the drill stop

turning for more than 30 seconds.

Refer to Figure 21

Turn system on by activating on-off switch

on monitor

head. If seed-cup shafts are turning, both indicator lights

are illuminated and no alarm sounds.

If any seed-cup shaft stops for 30 seconds, an alarm

sounds and the indicator for that section flashes on the

monitor, designating the failed shaft.

Note: The 30-second delay is to prevent nuisance alarms

when turning at the end of the field.

Note: If a failure does occur and an alarm sounds, re-

member you have traveled for 30 seconds without

planting with that drill section. If due to wheel lift or

low tire pressure, you may have been planting at

progressively lower populations before that.

Figure 21

Shaft Monitor Head

27049

1

2

1

2