Drive type – Great Plains 2510HDF Operator Manual User Manual

Page 36

32

1510HDF/2010HDF/2510HDF

Great Plains Manufacturing, Inc.

288-340M

2013-11-11

Drive Type

Before setting the Drive Type, rotate the gauge wheels.

Check that seed meters, seed tubes and drives are

working properly and free from foreign material.

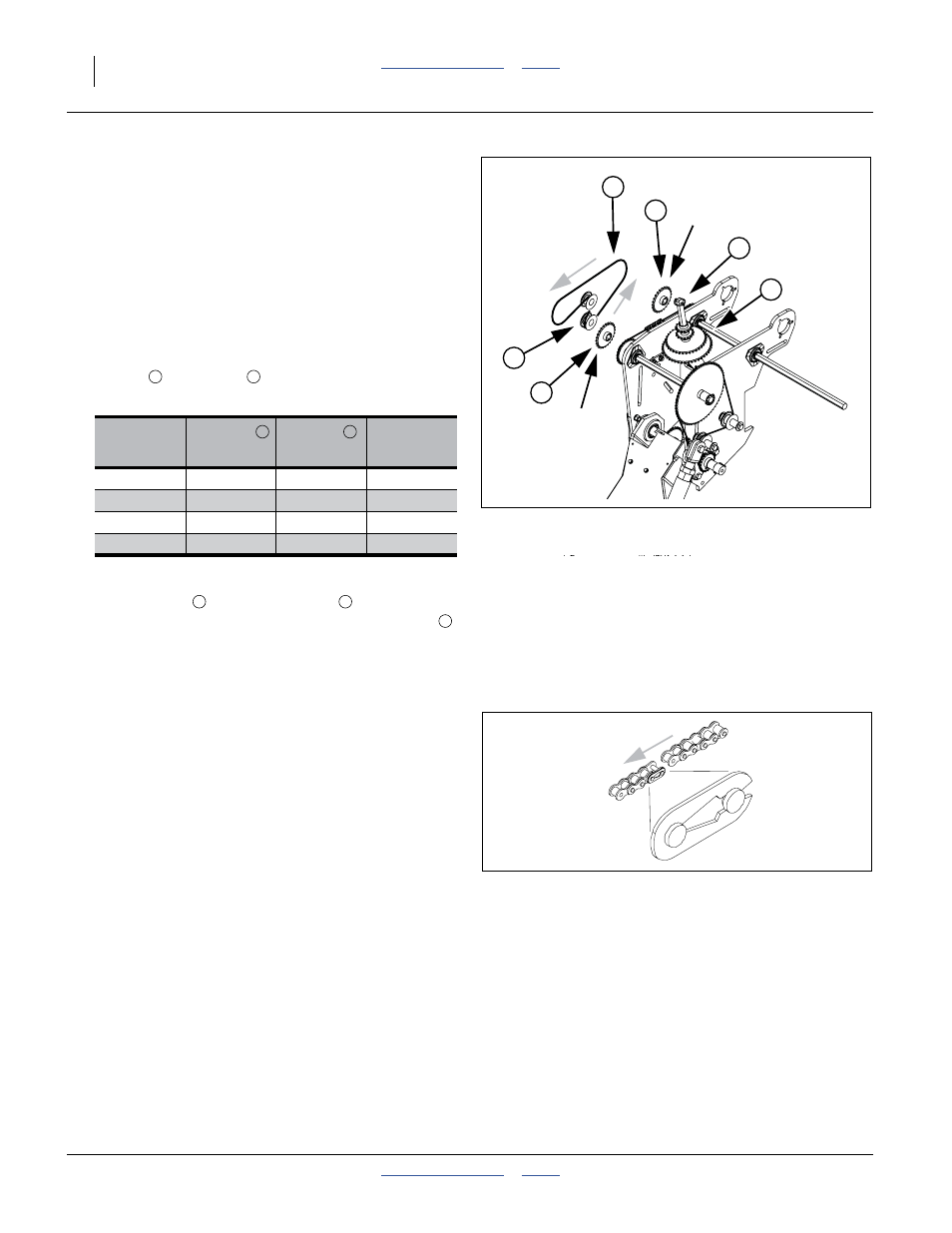

Refer to Figure 25

1.

Consult the rate charts in the Seed Rate manual,

and determine the Drive Type required. If there are

multiple choices (different Drive Types) for the same

seed population, choose the one that has a rate han-

dle setting closest to 50.

2.

These Types correspond to the following pairings of

Driving

and Driven

sprockets mounted on the

right side of the gauge wheel assembly.

If the Drive Type needs to be changed:

3.

Loosen idlers

and remove chain

. Remove

retaining pins at shafts and at storage tower shaft

.

4.

Exchange sprockets between drive shafts and

towers, installing the correct sprockets on the

DRIVER and DRIVEN shafts.

Refer to Figure 26

5.

Reroute chain over sprockets and idlers. Make sure

open end of chain clip faces away from direction of

chain travel (shown by gray arrows).

6.

Move idler into chain so chain has

1

⁄

4

in slack in its

longest span. Tighten idler. Re-pin all three shafts.

7.

Configure other gauge wheel to match.

Note: Each gauge wheel drives half of the drill. If a chain

breaks or is removed, that drill half does not plant.

Drive

Type

Driving

Sprocket

Driven

Sprocket

Coarse

Speed

1

14

44

Slowest

2

24

36

2.1x

3

24

24

3.1x

4

24

15

5.0x

Figure 25

Drive Type Sprockets

27222

DRIVING

DRIVEN

1

2

6

3

4

5

1

2

1

2

3

4

6

Figure 26

Chain Clip Orientation

26482