Hose routing hitch, Gauge wheel (optional), Hose routing hitch gauge wheel (optional) – Great Plains 3000TM Assembly Manual User Manual

Page 36

32

1800-3000TM

Great Plains Manufacturing, Inc.

586-536Q-ENG

11/12/2013

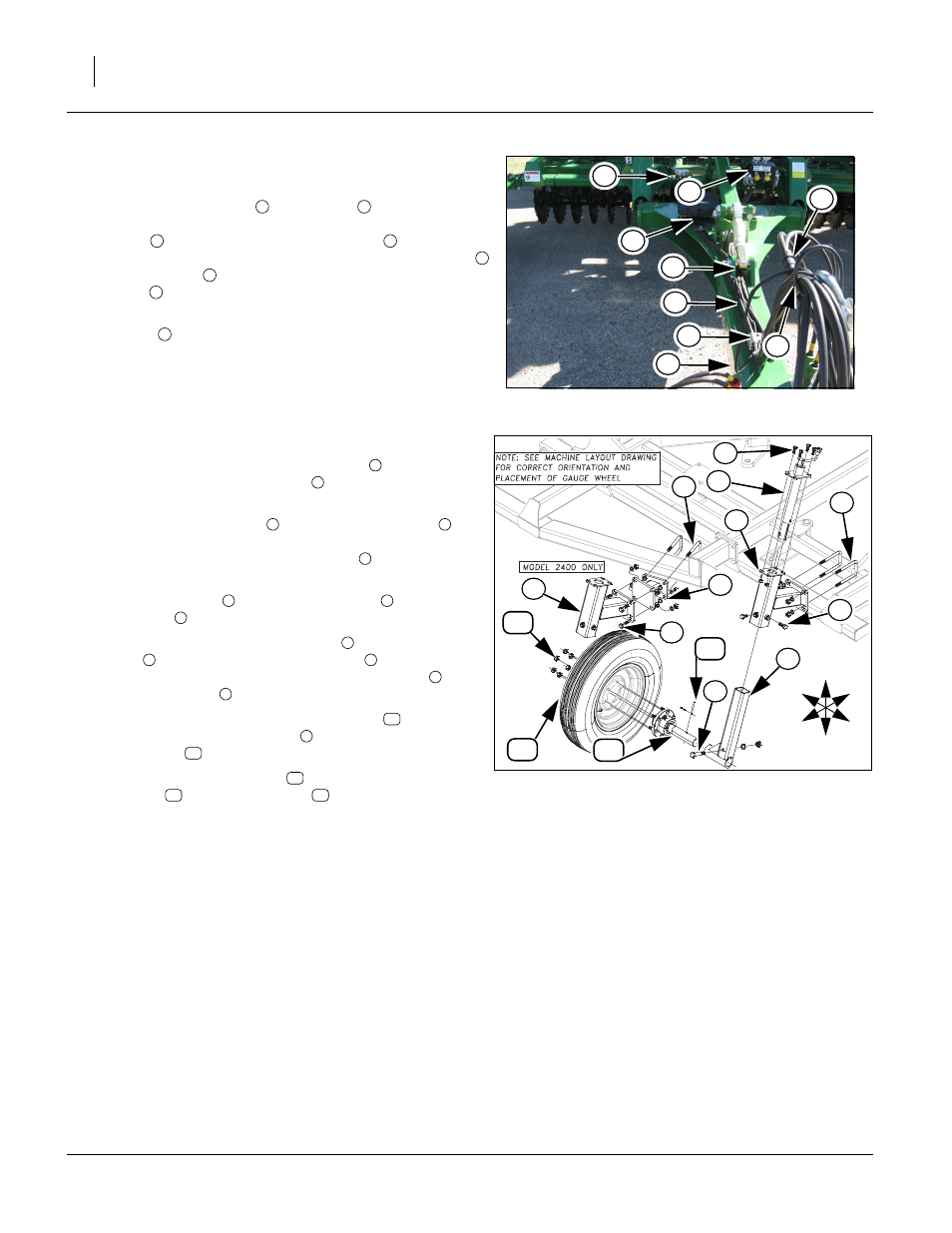

Hose Routing Hitch

Refer to Figure 28

120.Route hydraulic hoses

from valves

, on center brace

bar, gang hoses and light harness, under manual pak

bracket

, under front of hitch turnbuckle

along all

hose clamp blocks and through spring hose holder loop

to front of hitch

as shown. Secure hoses with hose

clamps

, 5/16 hex bolts and 5/16 lock washers.

Note: Be sure all hose clamp bolts are tight. Attach hose

wraps

as needed. Check that all hoses on machine

are fastened properly and they won’t get pinched at

hinge points or drag on ground. Check all connections

again for leaks.

Gauge Wheel (optional)

Refer to Figure 29

121.Model 2400, install gauge angle mount

to wing brace

with 5/8 x 3 1/32 x 6 1/2 u-bolts

, 5/8 lock washers and 5/

8 nuts

122.Install wheel arm mount

to gauge angle mount

on

wing brace with 5/8 x 2 hex bolts (Model 2400) or wing

frame with 5/8 x 3 1/32 x 6 1/2 u-bolts

(Models 1800 &

3000), secure with 5/8 lock washers and 5/8 nuts.

123.Attach screw jack

to wheel arm mount

with 1/2 x 1 1/

4 hex bolts

, 1/2 top lock nuts.

124.Slide gauge wheel spindle reciever

into wheel arm

mount

, secure with 3/4 x 4 hex bolts

, 3/4 lock wash-

ers and 3/4 nuts. Install the 5/8 x 1 1/4 hex bolts

to the

wheel arm mount

.

125.Align hole in 6-bolt hub/spindle assembly

with hole in

gauge wheel spindle reciever

, secure with 5/16 x 2 13/

16 clevis pin

and 1/8 x 1 cotter pin.

126.Attach wheel/tire assembly

to 6-bolt hub/spindle

assembly

with 9/16 lug nuts

.

127.Tighten all bolts with lock nuts snug, but do not torque.

The rest of the bolts may be tightened to specs, See

“Torque Values Chart” on page 38.

Figure 28

Hose Routing Hitch

42945

5

7

2

4

3

2

1

6

8

1

2

3

4

5

6

7

8

2

8

3

U

D

F

B

L

R

6

Figure 29

Gauge Wheel

43134

13

7

12

5

9

2

1

4

3

11

10

1

2

3

1

2

5

3

6

7

3

8

9

1

10

7

11

12

10

13