Center gang bar 2400-3000 – Great Plains 3000TM Assembly Manual User Manual

Page 26

22

1800-3000TM

Great Plains Manufacturing, Inc.

586-536Q-ENG

11/12/2013

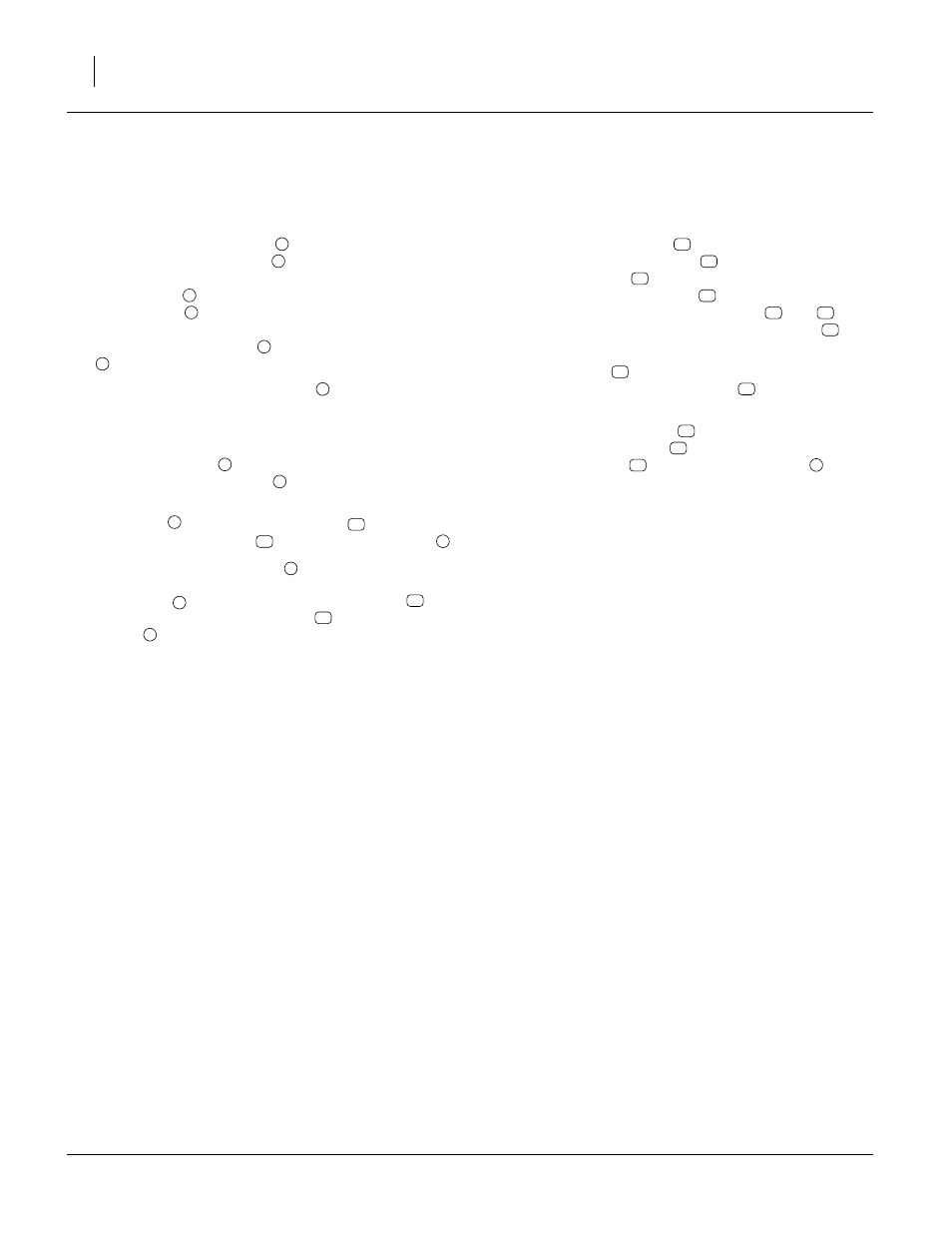

Center Gang Bar 2400-3000

Note: Refer to center gang bar assembly in “Parts Man-

ual” for correct part numbers of all components.

Refer to machine layout drawings in this manual

for correct gang assembly placement.

Refer to Figure 20

79. Position gang assemblies

in proper locations.

Install the gang pivot bolt

through tubes of gang

bars and tubes on center frame, secure with 1 1/4

flat washers

(one on top and one on bottom), 1 1/

4 slotted nut

(one on top and one on bottom).

Tighten bolts snug, torque to 350 to 400ft-lbs. Install

the 3/16 x 2 cotter pins

through 1 1/4 slotted nuts

and bend over to secure.

Note: Be sure turnbuckle assembly

is preset at 30 1/

4” before installing as shown below. See gang

angle adjustment in “Operator Manual” before

going to field.

80. Install rocker arm

to tube on center frame with 1 1/

4 x 10 special thread bolt

, secure with 1 1/4 top

lock nut.

81. Install link

with 1 x 3 1/4 clevis pin

, 1.5 x 1.00 x

0.075 machine washer

and 3/16 x 2 cotter pin

.

82. Install turnbuckle assembly

, adjustable end on ear

on front of rear gang bars and fixed end on rear of

rocker arm

. Secure with 1 x 3 1/4 clevis pin

, 1.5

x 1.00 x 0.075 machine washer

and 3/16 x 2 cot-

ter pin

.

83. Install the round tubes

(two on each gang bar)

between bottom front plate

(slotted hole toward

rear), rear plates

and plates on center frame.

Install the 3/4 x 6 hex bolts

, 3/4 lock washers and

3/4 nuts. Attach other ends of plates

and

to

bottom of center frame with 3/4 x 2 hex bolts

and

3/4 lock washers.

84. Install bracket

on bottom side of gang bar plate,

secure with 5/8 x 3 1/2 hex bolts

, 5/8 lock wash-

ers and 5/8 nuts.

85. Now the gang cylinders

may be hooked up with

the 1 x 3 1/8 clevis pin

, 1.5 x 1.00 x 0.075

machine washer

and 3/16 x 2 cotter pin

.

86. Hook gang cylinder hoses to gang cylinders, be sure

all fittings are tightened to specs, See “Hydraulic

Connector ID” on page 40. Now the gang system

may be purged of air, See “Purging Hydraulic Sys-

tem” on page 19.

87. Bolts may be tightened to specs, See “Torque Val-

ues Chart” on page 38 and all cotter pins may be

bent.

1

2

3

4

5

4

9

6

7

8

10

11

5

9

6

10

11

5

14

12

13

15

12

13

15

16

17

18

19

11

5