Liquid fertilizer rate, Setting liquid fertilizer rate – Great Plains YP2425F-2470 Material Rate User Manual

Page 39

2013-09-23

401-406B

Great Plains Manufacturing, Inc.

37

Liquid Fertilizer Rate

Setting Liquid Fertilizer Rate

Note: YP2425F dry fertilizer rate charts are found in

Supplement manual 403-362M.

If your planter is equipped with one or both optional

fertilizer manifold systems, it does not include the tank.

If the planter has a Type 2

a

(formerly referred to as a

“starter”) manifold, it may rely on an off-planter pump, or

may use one or two ground drive pumps on the planter.

For example, a Great Plains SML cart would use a

ground drive pump on the planter.

See “Ground Drive Fertilizer Rate” on page 40 for

ground drive pump configuration.

If the planter has a Type 3

(formerly referred to as a

“hi rate”) manifold, it relies on an off-planter pump,

typically the pump on a Great Plains PFC1600 or

PFC2000 tank cart.

Rate setting for a PFC cart pump is found in the cart’s

Operator manual.

Rate is controlled by the pump. Consistent distribution

requires using the correct size orifices in the manifolds. If

the orifice size is too large, flow may not be even across

all rows. If the orifice size is too small, material may be

dumped at the relief valve.

See “Liquid Fertilizer Rate” on page 37 for orifice

information.

The YP2425 planter optionally includes one or two

fertilizer manifolds, and may include one or two

ground-driven pumps for the Type 2 manifold. Tank(s)

and any off-planter pump(s) are usually located on a

trailing tank cart.

The Great Plains PFC1600 (single tank) and PFC2000

(dual tank) tanks include a single pump. Refer to the tank

Operator’s Manual for pump settings at the tank.

Fertilizer rate is independent of seed rate. Fertilizer rates

are set by the pump systems. On-planter ground drive

pump operations are described on page 40 and in the

YP2425 Operator’s Manual. Off-planter pump operations

are described in the tank manual.

Manifold systems include orifice plates at each row unit

drop line. Each fertilizer system normally includes a

pressure relief valve and strainer. These components

affect consistency of flow across all rows.

Adjust the relief valve(s) per the YP2425 Operator

Manual and/or tank Operator Manual.

a. Type 2 and Type 3 are described in the YP2425 Operator manual, under Setup topic “Fertilizer Connections”.

34128

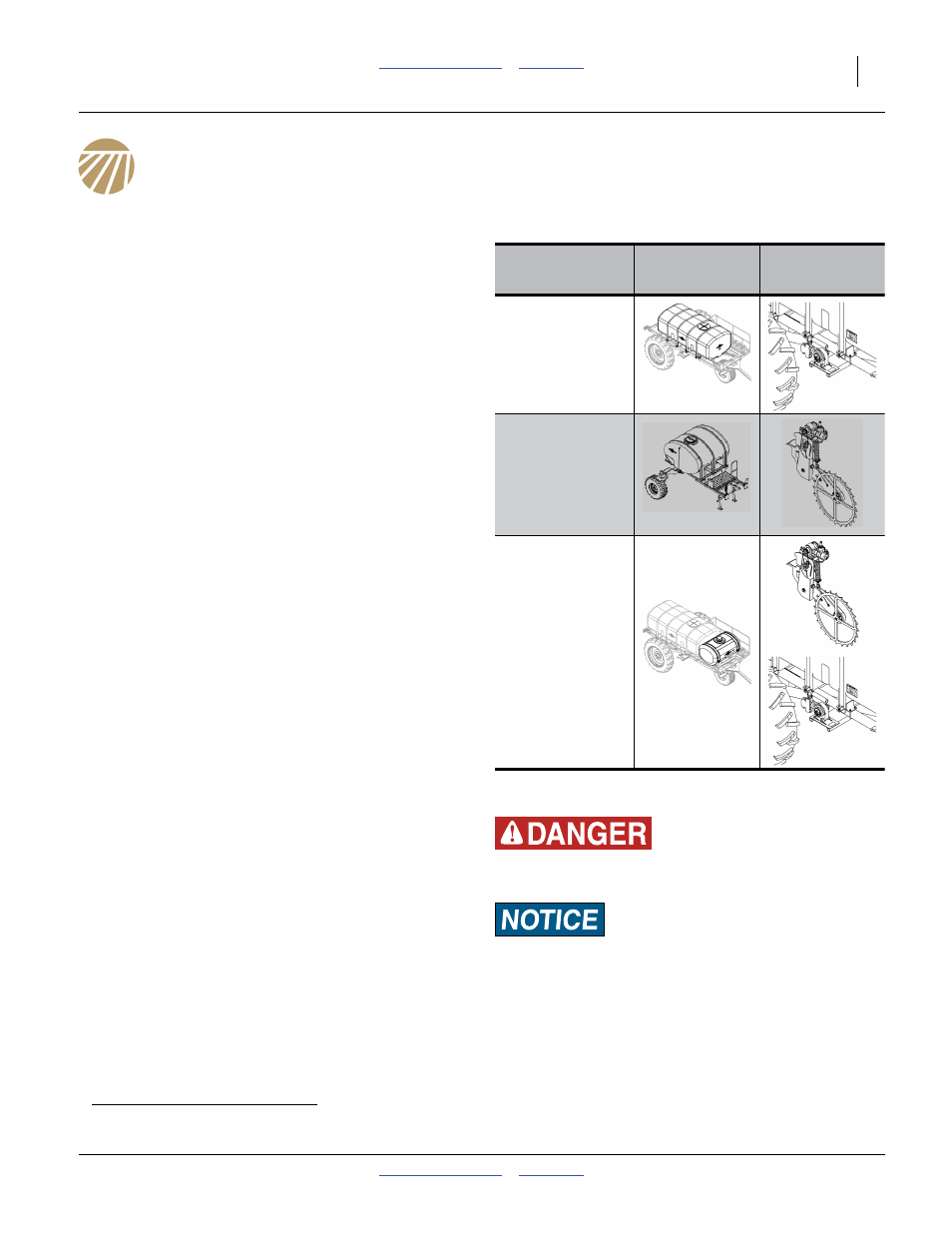

Installed

Manifold(s)

Source

(Tank)

Pump

Type 3

Type 2

Type 2

and

Type 3

Possible Chemical Hazard:

Wear protective gloves when changing orifice plates.

Material Loss/Equipment Damage Risk:

Set application rate at pump using pump drive chart., not by

orifice size. Orifice size is only used to create 15-65 PSI back

pressure to provide even flow between rows. An orifice size

too small causes material loss at relief valve. A size too large

can cause application imbalance across the planter.