CCI Thermal Technologies G Series - Industrial Infrared Gas Catalytic Heater User Manual

Page 4

4

Separate Installation and Operation Instructions are available for industrial heating applications.

6.0 OPERATION

All Cata-Dyne™ heaters are supplied with a

Safety Shut-Off Valve/Thermocouple assembly

to ensure the safe operation of the heater. Under

no circumstances should the reset button be held

or locked into the depressed position by use of a

mechanical restraint. A tamper resistant model

SSOV is available if desired.

6.1

Start-up

(i) Ensure the heater has been installed

according to all instructions and

relevant codes.

(ii) Turn on the main gas supply to

the system.

(iii) a. If the heater is equipped with a

low-flow thermostatic temperature

controller (capable of flow capacities

below 30,000 Btu/hr), rotate the dial

completely clockwise to the fully

open position.

b. If the heater is equipped with a

high-flow thermostatic temperature

controller (capable of flow capacities

above 30,000 Btu/hr), rotate the dial

completely counterclockwise to the

fully open position.

(iv) Turn on the power to the electrical elements.

(v) After 15 minutes, depress the reset

button on the top of the 100% safety

shut-off valve. The button should return

to the original position and internally

open the valve and allow gas to flow

to the heater. If the valve does not stay

open when the reset button is released,

it may be necessary to wait an additional

few minutes and then depress the reset

button again. This will allow the electrical

elements additional time to warm up.

(vi) When the catalytic reaction is well

established, turn off the electrical power

to the elements.

(vii) If the heater is equipped with a

thermostatic temperature controller, it

can be set to the desired setting after the

catalytic reaction has been established

for at least one hour.

6.2

Shut Down

(i) Turn off the gas supply to the heater.

6.3

Multi-Heater Start-up

(i) Cata-Dyne™ heaters can also be

purchased/installed

in

multi-heater

assemblies. If these assemblies are 12V,

each heater must be started individually.

This ensures the correct voltage and

current will be reaching the heater from

the power supply.

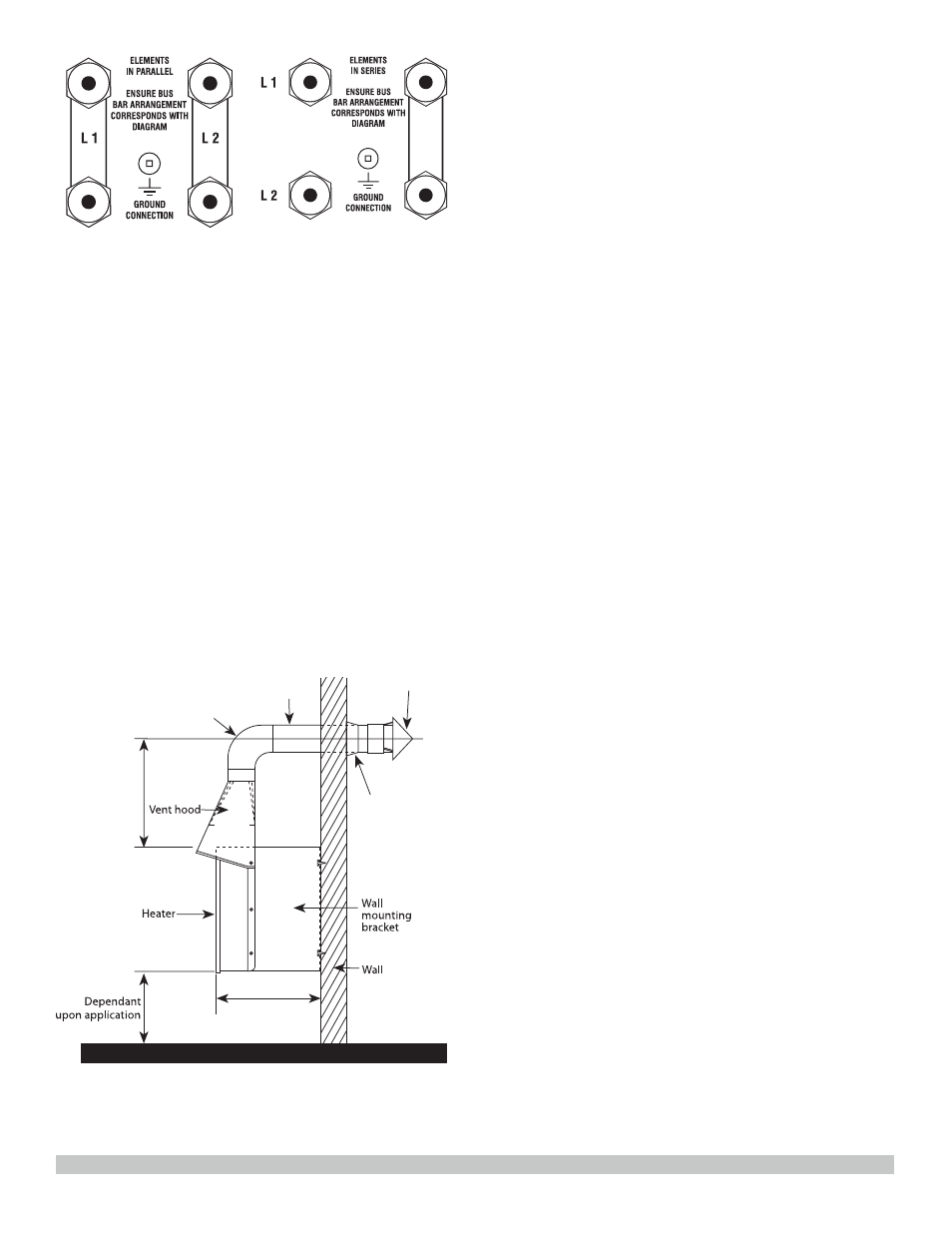

FIGURE 4 -

ELEMENTS IN PARALLEL

FIGURE 5 -

ELEMENTS IN SERIES

5.5

Ventilation

(i) The catalytic reaction in Cata-Dyne™

heaters occurs when natural gas or

propane reacts with oxygen to produce

water vapor, carbon dioxide and infrared

energy. Ventilation must be provided

to allow adequate supply of oxygen for

the reaction.

(ii) For every 1.0 ft

2

(0.093 m

2

) of heater

surface, 50 ft

3

/hr (1.42 m

3

/hr) of air

supply is required. For example, a WX 24

x 24 heater (20,000 Btu/hr / 5.857 kW)

would require 200 ft

3

/hr (5.66 m

3

/hr) of

air to ensure proper operation of the

Cata-Dyne™ heater.

(iii) To reduce the carbon dioxide and water

vapor concentrations in the building, a

vent hood assembly can be installed

to provide positive ventilation from the

heater (FIGURE 6).

15” approx.

11.5”

3” Flashing

3” Snow cap

3” Pipe

3” Elbow

FIGURE 6 - VENTILATION FROM HEATER